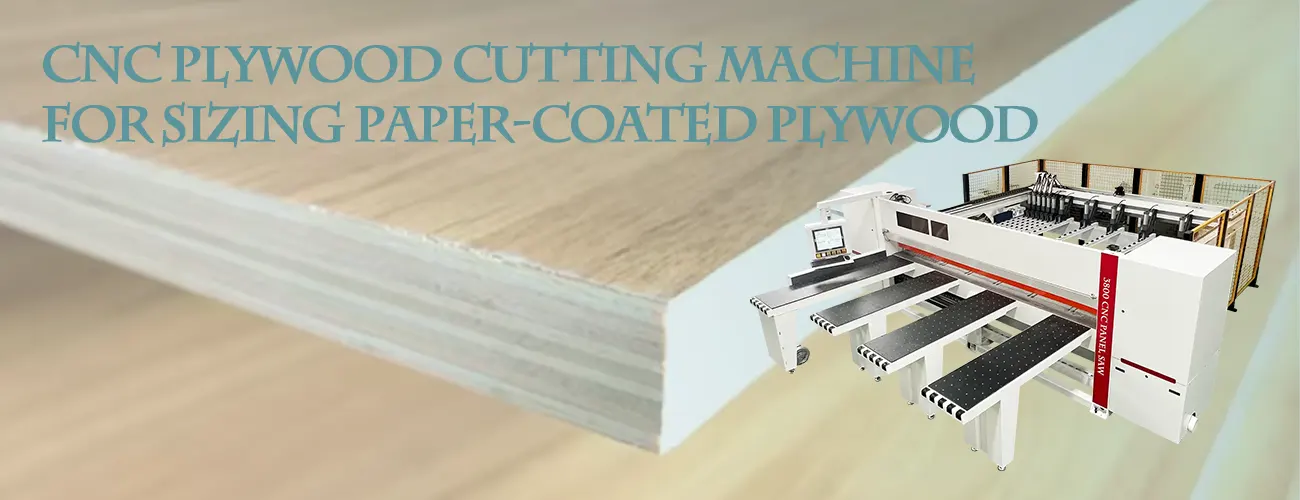

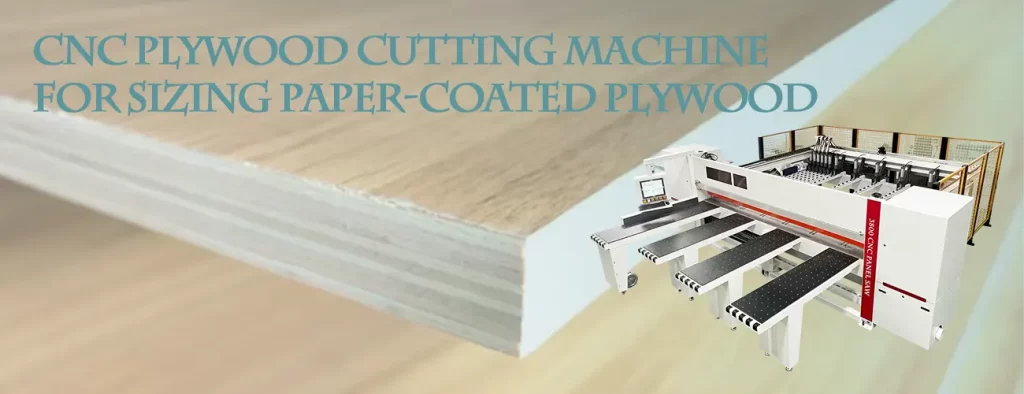

Streamline Production: CNC Plywood Cutting Machines for Paper-Coated Plywood Processing

Improve your woodworking projects with the power of CNC Plywood Cutting Machine

Paper-coated plywood, a versatile material gaining popularity in various applications, combines the strength and stability of plywood with the smooth, printable surface of paper. However, achieving precise cuts for this unique material requires specialized equipment. Here’s where a CNC plywood cutting machine, also known as a CNC plywood cutter or plywood CNC panel saw, comes in. These advanced machines offer unmatched precision, efficiency, and control for cutting paper-coated plywood, ensuring clean edges and flawless project execution.

What is Paper-Coated Plywood?

Paper-coated plywood is a composite material manufactured by permanently bonding a layer of high-quality paper to a plywood core. The paper layer, typically melamine paper, offers several benefits:

- Smooth and Printable Surface: The paper layer provides a smooth and even surface, ideal for printing designs, logos, or branding elements directly onto the plywood. This eliminates the need for additional laminates or veneers, streamlining the production process.

- Enhanced Durability: The paper layer acts as a protective barrier, enhancing the scratch and stain resistance of the plywood. This makes paper-coated plywood suitable for applications requiring a durable aesthetic finish, such as furniture, signage, or retail displays.

- Moisture Resistance: The melamine paper used in many paper-coated plywood options offers improved moisture resistance compared to untreated plywood. This makes it a viable option for applications with moderate humidity exposure, such as kitchens or bathrooms.

Features of Paper-Coated Plywood:

- Versatility: Paper-coated plywood comes in various plywood core options, including birch, poplar, and MDF (Medium-Density Fiberboard), allowing for customization based on project needs. The paper layer can also be available in a variety of colors and finishes, offering design flexibility.

- Machinability: The combination of paper and plywood core allows for clean and precise cutting using woodworking tools. However, due to the paper layer’s delicate nature, specialized cutting equipment like CNC plywood cutting machines is recommended for optimal results.

- Lightweight (compared to solid wood): The paper layer contributes to a slightly lighter weight compared to solid wood panels of the same size. This can be an advantage for certain applications where weight reduction is desirable.

How CNC Plywood Cutting Machines (CNC Plywood Cutters or Plywood CNC Panel Saws) are Utilized in Cutting Paper-Coated Plywood

CNC plywood cutting machines, also known as CNC plywood cutters or plywood CNC panel saws, offer unparalleled advantages for cutting paper-coated plywood:

- Computerized Control (CNC): These machines are computer-controlled, allowing for precise programming of cutting paths. This ensures consistent and repeatable cuts for all your paper-coated plywood components, regardless of complexity.

- High-Precision Cutting Systems: Advanced cutting systems with high-quality cutting tools, such as router bits or specialized blades optimized for paper-coated materials, are employed. This minimizes chipping or delamination of the paper layer, preserving the integrity of the material and ensuring a clean, professional finish.

- Vacuum Hold-Down Systems: Many CNC plywood cutting machines utilize integrated vacuum hold-down systems. This ensures that the paper-coated plywood sheet remains securely fixed during the cutting process, preventing movement or warping, which could damage the paper layer.

- Dust Extraction Systems: Dust extraction systems effectively capture dust particles generated during cutting. This maintains a clean working environment, minimizes the risk of respiratory irritation, and allows for better visibility during cutting operations, crucial for achieving precise results.

- Nesting Capabilities: Advanced CNC plywood cutting machines often boast nesting software features. This functionality optimizes material usage by arranging multiple cuts within the paper-coated plywood sheet, minimizing scrap and maximizing material utilization.

Advantages of Our CNC Plywood Cutting Machines (CNC Plywood Cutters or Plywood CNC Panel Saws) in Sizing Paper-Coated Plywood

Investing in a dedicated CNC plywood cutting machine (CNC plywood cutter or plywood CNC panel saw) from our company offers several advantages for efficient and precise paper-coated plywood processing:

- Superior Cutting Performance: Our industrial-grade CNC machines ensure clean and accurate cuts, minimizing waste and preserving the integrity of your paper-coated plywood. This translates to a professional-looking finished product with minimal rework required, saving you time and resources.

- Enhanced Workflow Efficiency: The automation, precision, and nesting capabilities of our CNC plywood cutting machines significantly reduce cutting times compared to manual methods. This translates to faster project completion, improved production throughput, and increased productivity for your operation.

- Reduced Material Waste: Precision cutting systems and nesting features minimize scrap material, allowing you to optimize the use of your paper-coated plywood sheets.

- Reduced Material Waste: Precision cutting systems and nesting features minimize scrap material, allowing you to optimize the use of your paper-coated plywood sheets. This not only reduces material costs but also aligns with responsible resource management practices.

- Versatility for Diverse Projects: Our CNC plywood cutting machines can handle various paper-coated plywood sizes and thicknesses. They can also navigate intricate shapes and complex designs with ease. This versatility makes them suitable for a wide range of applications, from signage and displays to furniture components and bespoke design projects.

- Scalability for Growing Businesses: CNC plywood cutting machines offer scalability for businesses of all sizes. As your production demands increase, these machines can adapt to handle larger workloads and more intricate projects, supporting your business growth.

Beyond Efficiency: Unleashing the Creative Potential of CNC Plywood Cutting Machines

While the efficiency gains are undeniable, the benefits of CNC plywood cutting machines extend beyond simply cutting paper-coated plywood faster and with less waste. These machines unlock a whole new realm of creative possibilities for designers and fabricators:

- Intricate Designs and Lettering: The precise control of CNC cutting allows for the creation of intricate designs, lettering, or logos directly onto the paper surface of the plywood. This eliminates the need for additional processes like stenciling or hand-painting, streamlining production and creating unique visual elements for your projects.

- Precise Cutouts for Inlays and Overlays: CNC machines excel at creating precise cutouts for inlays and overlays on paper-coated plywood. This allows for the incorporation of contrasting wood pieces, veneers, or even acrylic elements into the design, adding depth and visual interest to your creations.

- Customized Signage and Displays: The ability to print directly onto the paper surface combined with precise CNC cutting makes paper-coated plywood ideal for creating customized signage and displays. This allows for high-quality, durable, and visually impactful presentations for branding, advertising, or point-of-purchase displays.

- Efficient Prototyping: The ability to quickly and accurately cut prototypes from paper-coated plywood makes CNC machines ideal for product development and design exploration. This allows designers and fabricators to experiment with different shapes, sizes, and design elements before committing to final production runs, saving time and material during the design process.

Investing in the Future of Paper-Coated Plywood Fabrication

By incorporating a CNC plywood cutting machine (CNC plywood cutter or plywood CNC panel saw) into your fabrication process, you gain a powerful tool for efficient and precise paper-coated plywood processing. Our industrial-grade CNC machines not only streamline your workflow and minimize waste but also unlock a world of creative possibilities. Contact us today to learn more about how our advanced CNC technology can revolutionize your approach to paper-coated plywood cutting and empower you to bring your design visions to life.