Engineered Precision: steel beam cutting saws for Multilayer Solid Wood Processing

Improve your woodworking projects with the power of Steel Beam Cutting Saws

Multilayer solid wood, also known as Glulam (Glued Laminated Timber), is an increasingly popular building material offering superior strength, stability, and design flexibility. However, processing these large and robust beams requires specialized cutting equipment. Here’s where steel beam cutting saws, also known as post and beam saws, excel. These industrial-grade saws provide the power and precision needed to efficiently and accurately cut multilayer solid wood, ensuring seamless integration into your construction projects.

What is Multilayer Solid Wood (Glulam)?

Multilayer solid wood, or Glulam, is an engineered wood product composed of multiple layers of solid wood lumber bonded together with structural adhesives. The individual layers, typically made from finger-jointed boards of spruce, pine, or other suitable wood species, are arranged in a specific orientation to achieve optimal strength and dimensional stability. This engineered approach offers several advantages compared to traditional solid wood beams.

Features of Multilayer Solid Wood (Glulam):

- Superior Strength: The layered structure of Glulam beams allows them to achieve significantly higher load-bearing capacity compared to solid wood beams of the same size. This makes them ideal for applications requiring long spans or heavy weight support, such as beams in large buildings, bridges, or roof structures.

- Dimensional Stability: Glulam exhibits minimal shrinkage and warping compared to solid wood. This dimensional stability is crucial for maintaining structural integrity and preventing cracking or distortion in the finished building.

- Design Flexibility: Glulam beams can be manufactured in various lengths, widths, and curved shapes to accommodate diverse architectural designs. This allows for the creation of visually striking and structurally sound elements that complement modern building aesthetics.

- Sustainable Choice: Glulam offers an environmentally friendly alternative to solid wood beams. By utilizing smaller wood pieces and maximizing material utilization, it promotes sustainable forestry practices and reduces reliance on clear-cutting large trees.

How Steel Beam Cutting Saws (Post and Beam Saws) are Utilized in Cutting Multilayer Solid Wood (Glulam)

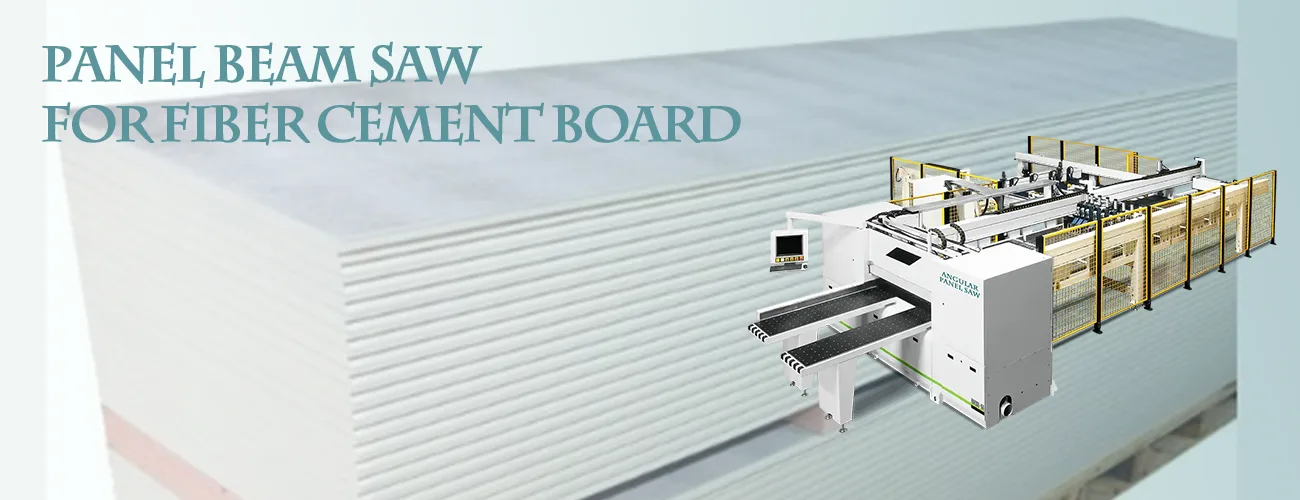

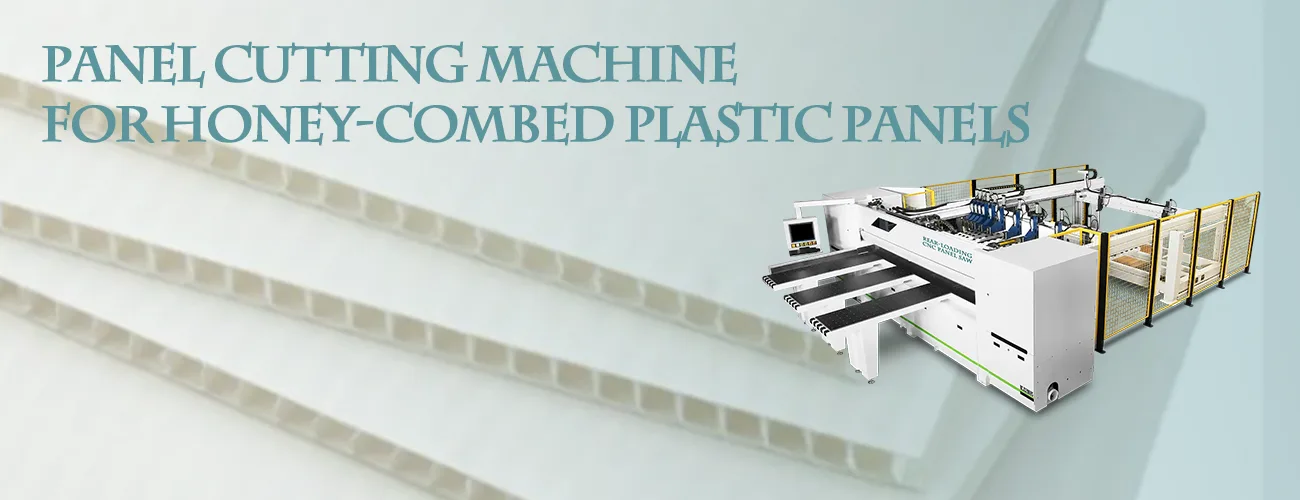

Steel beam cutting saws (steel beam saw), also known as post and beam saws, are specifically designed for the demanding task of cutting multilayer solid wood (Glulam) beams. Here’s how these powerful saws ensure efficient and precise processing:

- Industrial-Grade Construction: Steel beam cutting saws are built for heavy-duty use with robust steel frames and powerful motors. This ensures they can handle the large size and weight of Glulam beams without compromising on cutting performance.

- High-Capacity Blades: These saws utilize specialized blades designed for cutting dense wood materials. These blades are typically large in diameter and made from high-quality steel alloys to ensure clean and chip-free cuts through multiple layers of Glulam.

- Precise Cutting Systems: Advanced cutting systems with features like laser guides and adjustable feed rates allow for precise control over the cutting process. This minimizes deviations and ensures all Glulam beams are cut to exact specifications, crucial for maintaining structural integrity in your building project.

- Automated Features (Optional): Some advanced steel beam cutting saws offer optional automation features, such as automatic feed systems and CNC (Computer Numerical Control) programming. These features streamline repetitive cutting processes, boosting productivity and minimizing human error for complex cuts.

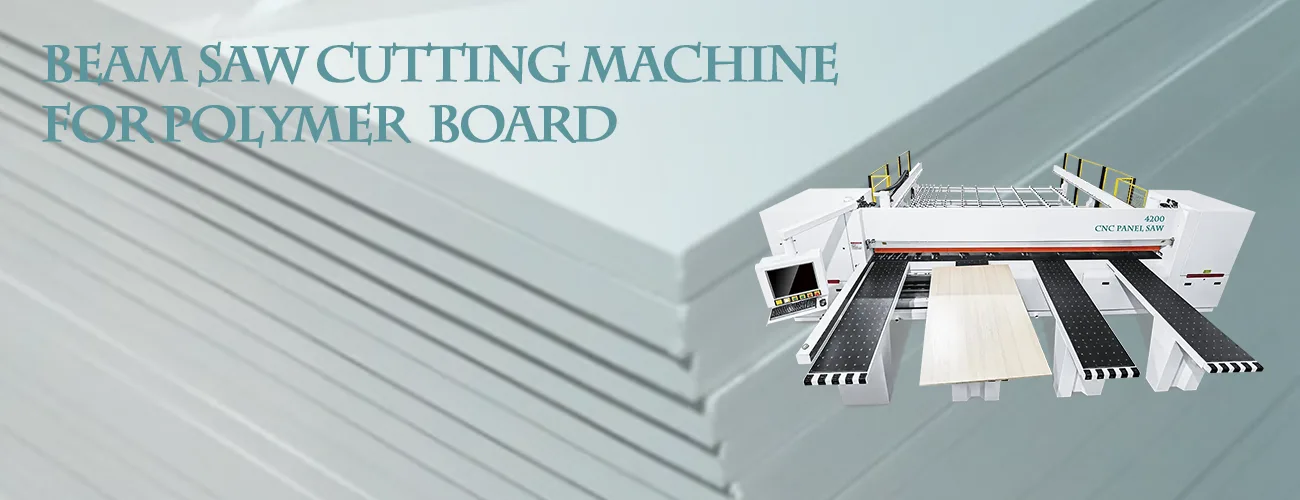

Advantages of Our Steel Beam Cutting Saws (Post and Beam Saws) in Sizing Multilayer Solid Wood (Glulam)

Investing in a dedicated steel beam cutting saw (post and beam saw) from our company offers several advantages for efficient and reliable processing of multilayer solid wood (Glulam):

- Effortless Cutting Performance: Our industrial-grade saws handle even the most challenging Glulam beams with ease, ensuring clean and precise cuts every time. This translates to less rework, reduced waste, and a professional-looking finished product for your construction projects.

- Enhanced Workflow Efficiency: The power and efficiency of our steel beam cutting saws significantly reduce cutting times compared to traditional methods. This translates to faster project completion, increased production capacity, and improved overall workflow on your construction site.

- Dimensional Accuracy: Precision cutting systems and user-friendly controls ensure all Glulam beams are cut to exact specifications. This minimizes the risk of errors during construction and guarantees the structural integrity of your building.

- Versatility for Diverse Projects: Our steel beam cutting saws can handle a wide range of Glulam beam sizes and thicknesses, accommodating various construction projects. This versatility allows you to handle everything from standard Glulam beams to custom-sized elements for unique architectural designs.

- Safety Features: Our saws prioritize safety with features like blade guards, dust extraction systems, and emergency shut-off switches. These features create a safe working environment for your operators, minimizing the risk of accidents and injuries during the cutting process.

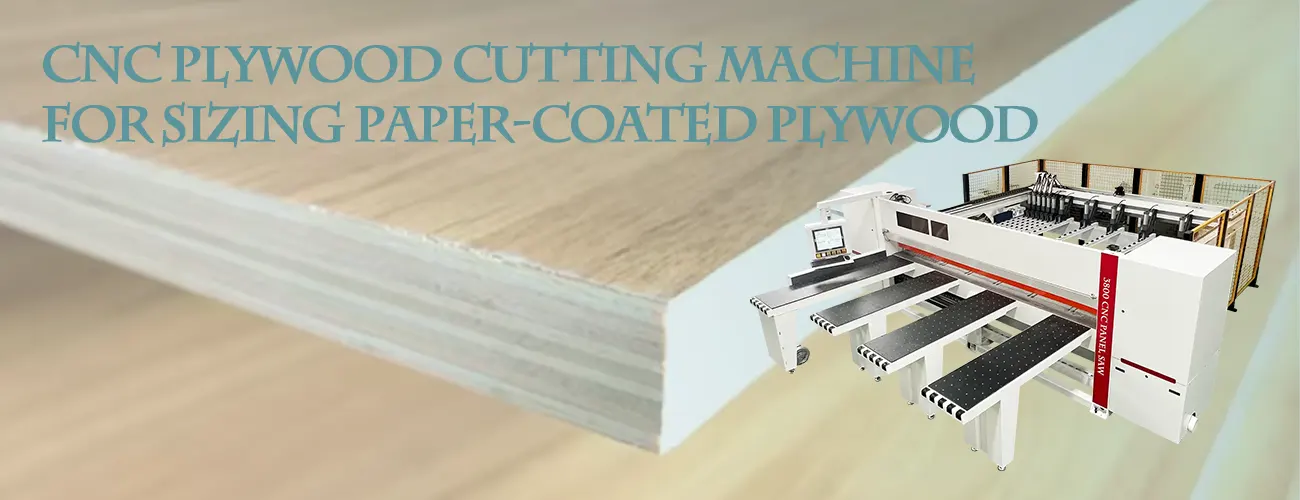

Beyond Efficiency: The Creative Potential of Steel Beam Cutting Saws

While the focus lies on efficient and precise cutting, steel beam cutting saws (post and beam saws) offer additional possibilities for builders and architects working with Glulam:

- Complex Beam Fabrication: The precise cutting capabilities of these saws allow for the creation of complex beam shapes with angled cuts, notches, or integrated connector elements. This eliminates the need for additional fabrication steps and streamlines the overall construction process.

- Curved Beam Designs: Advanced steel beam cutting saws with specialized attachments can handle curved cuts in Glulam beams. This opens doors for incorporating aesthetically pleasing curved elements into building designs, such as arched beams or vaulted ceilings.

- Prefabrication Potential: The ability to precisely cut and prepare Glulam beams off-site using steel beam cutting saws allows for efficient prefabrication. This translates to faster on-site construction and minimizes disruption at the building location.

The Future of Sustainable Construction with Multilayer Solid Wood

Multilayer solid wood (Glulam) is a key material shaping the future of sustainable construction. By offering superior strength, design flexibility, and efficient utilization of wood resources, Glulam promotes environmentally responsible building practices. Steel beam cutting saws, with their capability for precise and efficient processing, play a crucial role in unlocking the full potential of this sustainable building material.

Contact us today to learn more about how our industrial-grade steel beam cutting saws (post and beam saws) can empower your construction projects with efficient Glulam processing and precise cutting solutions. Invest in the future of sustainable building and elevate your construction projects with confidence.