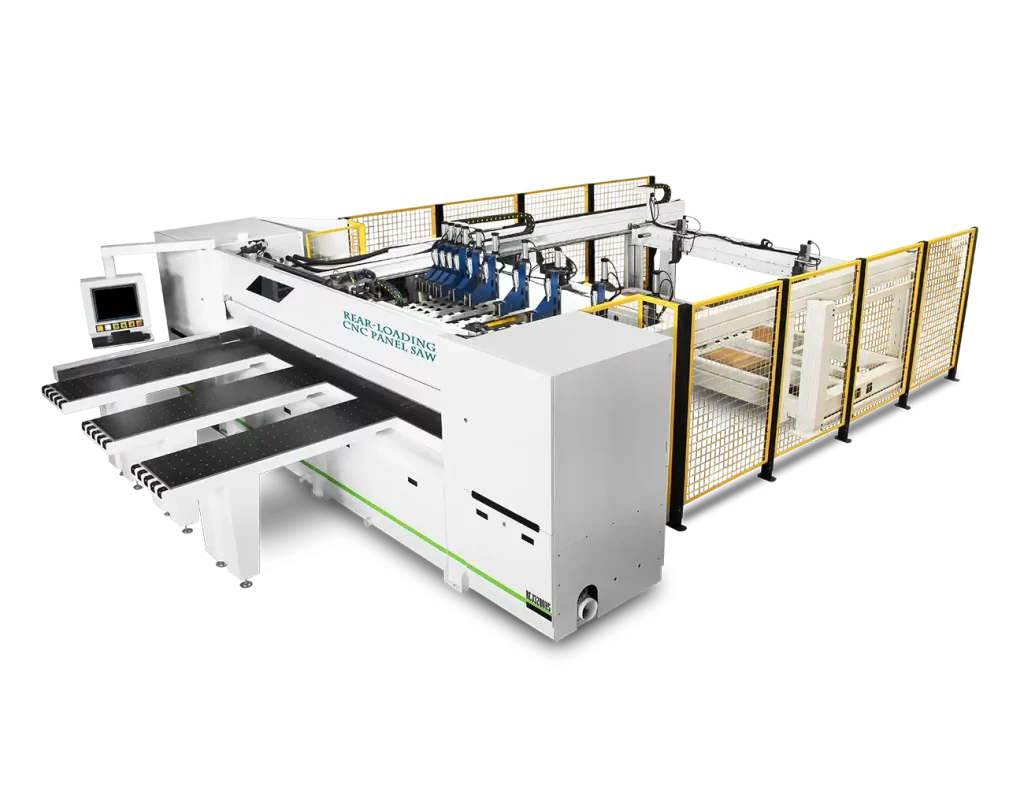

Advanced Technology

Built with cutting-edge technology, this machine is built to withstand demanding workloads and deliver long-term performance.

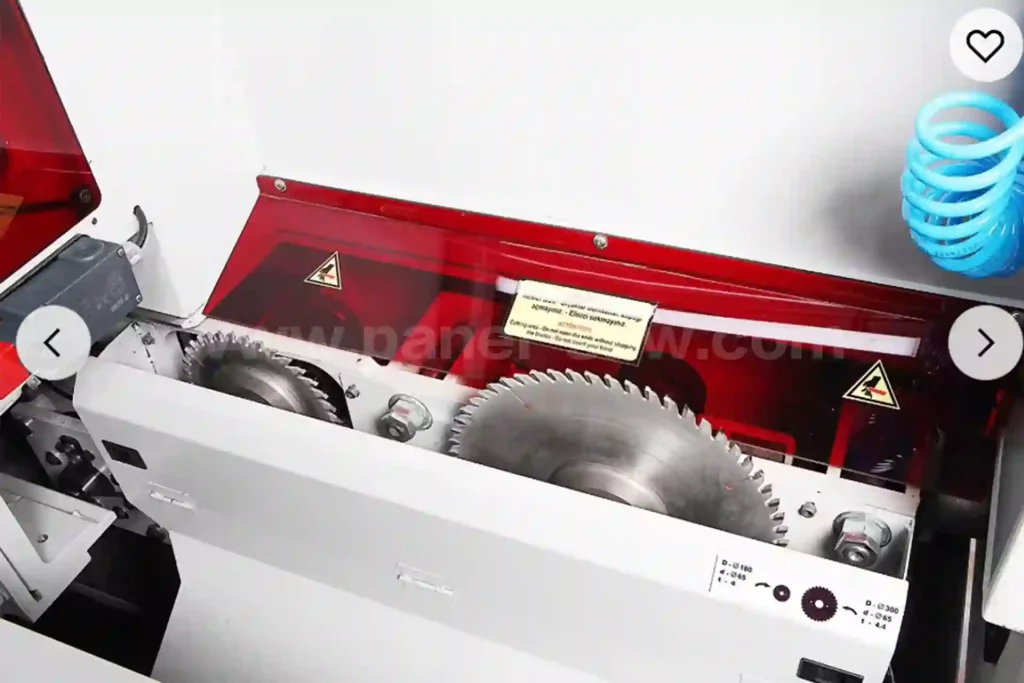

German-type Saw Shaft:

This high-quality saw shaft ensures clean and precise cuts.

Large and Small Saw with Separate Structures

This configuration offers optimal cutting performance for various material thicknesses.

Overall Trolley Design

This design enhances stability and cutting accuracy.