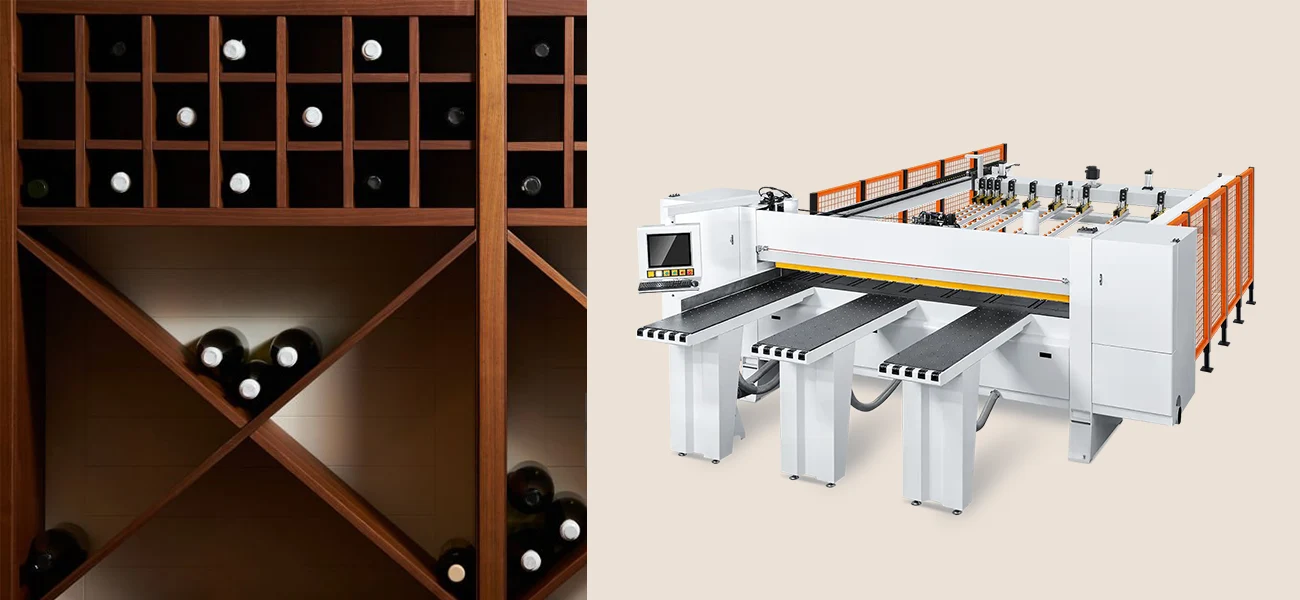

Streamline Wood Door Production: Panel Sizing Powerhouse - CNC Panel Saws for Sale

Wood door production is a multi-step process, and panel sizing is the crucial first step. Here at our company, we understand the importance of efficiency and precision in every stage. That’s why we offer a comprehensive range of CNC panel saws for sale, the perfect cutting machinery for your wood door production line.

From Forest to Function: The Journey of Plywood and Wooden Doors

The doors we take for granted in our daily lives undergo a fascinating transformation before reaching our homes. Here’s a glimpse into the multi-stage journey of plywood and wooden doors:

The Foundation: Selecting the Right Timber

The process starts with meticulous selection of wood. Popular choices for doors include pine, oak, cherry, mahogany, and maple, each offering unique aesthetics and properties. Plywood doors utilize thin layers of wood veneer, ensuring strength while optimizing resource usage.

Shaping the Vision: Cutting and Prepping the Wood

Skilled artisans meticulously cut the chosen wood into precise shapes based on the door design. Saws, routers, and other cutting tools transform raw timber into the building blocks of the final product.

Strength in Layers: Crafting the Plywood Core

For plywood doors, thin wood veneers become a symphony of strength. Each layer is meticulously glued with its grain running perpendicular to the adjacent layer, creating a cross-grain structure that boasts exceptional stability and resistance to warping. High pressure presses then forge these layers into a solid and robust panel.

Building the Frame: The Door’s Skeleton Takes Shape

The door’s skeletal frame takes form by joining stiles (vertical components) and rails (horizontal components). This framework provides crucial support and structure for the entire door. To further enhance the visual appeal, decorative moldings can be added during this stage.

Panel Integration: Adding Depth and Design (for paneled doors only)

If the door design incorporates panels, carefully selected pieces (solid wood, plywood, or other materials) are meticulously inserted into the pre-built frame. These panels contribute not only to aesthetics but can also offer additional soundproofing or insulation qualities.

Creating a Cohesive Unit: Joining the Elements

The frame and panels are then securely joined together using a combination of glue, dowels, or other fastening techniques. This stage creates the fundamental structure of the door.

A Flawless Finish: Sanding and Coating for Beauty and Protection

The door undergoes a meticulous sanding process to eliminate any roughness or imperfections. Following this, the door is adorned with a protective and aesthetically pleasing finish. This might include stains, paints, varnishes, or other coatings, depending on the desired look and functionality.

Adding Functionality: Hardware Installation

Hinges, doorknobs, locks, and other hardware components are installed at this stage, transforming the meticulously crafted structure into a fully functional door.

Quality Assurance: Ensuring Perfection

The finished door undergoes a rigorous inspection process to guarantee it meets stringent quality standards in terms of dimensions, finish, and functionality. This ensures a flawless user experience.

Ready for Their Journey: Packaging and Distribution

Once quality control procedures are complete, the doors are carefully packaged and prepared for shipment. They then embark on their final journey to distributors, retailers, or directly to customers, ready to adorn homes and buildings.

This overview provides a glimpse into the intricate process that transforms raw wood into the functional and beautiful doors we rely on every day. The specific steps and materials used may vary depending on the manufacturer, door type, and desired level of quality and aesthetics.

The Power of CNC Panel Saws:

CNC panel saws are the workhorses of panel sizing for plywood door production. They bring automation, computer control, and intelligent features to the process, delivering a wealth of benefits:

- Unmatched Accuracy: Computer-controlled precision ensures every panel is cut to exact dimensions, minimizing material waste and maximizing production yield.

- Streamlined Workflow: Automated cutting processes eliminate manual operations, saving time and labor costs.

- Increased Efficiency: Intelligent software optimizes cutting layouts to minimize scrap and maximize material utilization.

- Reduced Errors: Automated processes minimize human error, leading to consistent quality and fewer production delays.

- Proven Performance: Our CNC panel saws boast a long history of reliable operation in demanding wood door production environments.

Finding the Perfect Fit: A Range of Panel Saw Options

We understand that different door manufacturers have diverse needs. That’s why we offer a variety of CNC panel saw models to suit your specific production requirements:

- Cutting Capacity: Choose from sizes including 2800mm, 3300mm, 3800mm, 4200mm, and 4600mm to accommodate your typical panel dimensions.

- Loading Style: Select between front-loading and back-loading models to fit your workflow preferences.

- Ultimate Efficiency: For the most efficient cutting solution, consider our angular panel saw. This innovative machine combines horizontal and vertical cutting in one step, maximizing throughput and saving valuable floor space.

Proven Performance and Trusted Quality:

Our angular panel saws deliver exceptional value, featuring performance comparable to industry leaders like Homag and Schelling. We utilize a meticulous manufacturing process that includes:

- High-Strength Steel Construction: Ensuring long-lasting durability and maintaining cutting accuracy over time.

- Precise Engineering: Every component is meticulously designed and manufactured for optimal performance.

- Advanced Technology: We incorporate cutting-edge software and automation features for a seamless user experience.

Invest in Efficiency and Quality: CNC Panel Saws for Your Success

Explore our diverse range of CNC panel saws for sale today and find the perfect solution to revolutionize your wood door production line. Contact us to discuss your specific needs and let our experienced team guide you towards achieving optimal panel sizing efficiency.