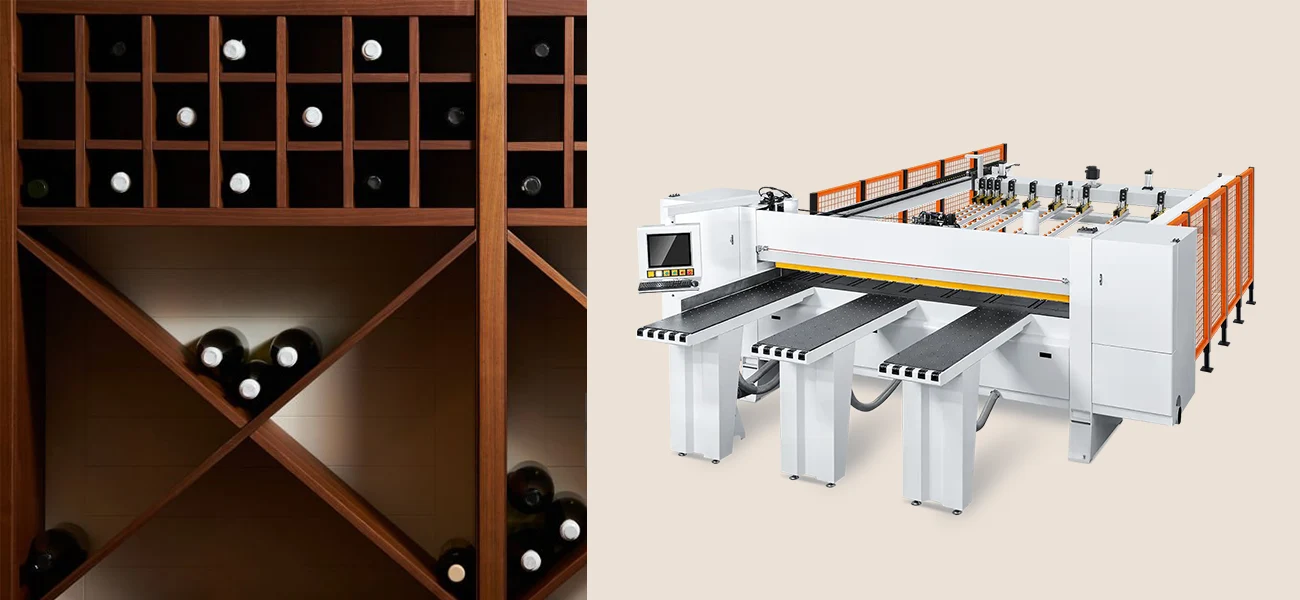

Streamline Wood Wardrobe Production: Top China CNC Wood Cutter Machine Manufacturer

Elevate your wood wardrobe production with cutting-edge technology from China’s leading CNC wood cutter machine manufacturer. Here at our factory we understand the importance of precision and efficiency in every stage of furniture making, particularly during material preparation, the first and critical step.

Making your home sweet and nice: The production process of wooden wardrobe

The wood wardrobe manufacturing process involves several stages, including design, engineering, prototyping, production, quality control, and shipping:

Production is a crucial part of the furniture manufacturing process as it involves the actual manufacturing and assembly of the furniture. The production process includes several steps:

- Materials Preparation: The initial step in production is preparing the materials needed to create the furniture. This involves cutting, shaping, and sanding raw materials such as wood, metal, or upholstery fabric.

- Assembly: Once the materials are prepared, the furniture is assembled according to the final design. This step uses tools, machines, and manual labor to put the furniture together, including attaching legs, frames, and hardware.

- Finishing: After assembly, the furniture undergoes finishing, which involves applying a protective coating—such as paint, varnish, or stain—to enhance its appearance and protect it from wear and tear.

- Quality Control: Throughout the production process, the furniture undergoes quality control checks to ensure it meets required standards for safety, functionality, and durability. These checks include visual inspections, functional testing, and load-bearing tests.

- Packaging and Shipping: Once the furniture passes quality control, it is packaged and shipped to customers. Packaging involves wrapping the furniture in protective materials to prevent damage during transit.

- After-Sales Service: After delivery, manufacturers may offer after-sales services such as installation, repair, or replacement of defective parts to ensure customer satisfaction and maintain their reputation.

In summary, production is a vital part of the furniture manufacturing process, encompassing the actual creation and assembly of the furniture.

The Power of CNC Cutting: Redefining Efficiency

CNC wood cutter machines are revolutionizing wood wardrobe production. These innovative machines offer a multitude of benefits for your business:

- Unmatched Accuracy: Computer-controlled cutting ensures every wood component is sized to exact specifications, minimizing material waste and maximizing production yield.

- Effortless Workflow: Automated cutting processes eliminate manual operations, saving valuable time and labor resources.

- Intelligent Optimization: Advanced software optimizes cutting layouts to minimize scrap and maximize material utilization.

- Reduced Errors: Automated processes minimize human error, leading to consistent quality and fewer production delays.

- Proven Performance: Our CNC wood cutter machines boast a long history of reliable operation in demanding furniture manufacturing environments.

Finding the Perfect Fit: A Spectrum of CNC Wood Cutters

We understand that furniture makers have diverse needs. That’s why we offer a comprehensive range of CNC wood cutter machine models to suit your specific production requirements:

- Variable Cutting Capacities: Choose from sizes including 2800mm, 3300mm, 3800mm, 4200mm, and 4600mm to accommodate your typical wood wardrobe panel dimensions.

- Flexible Loading Options: Select between front-loading and back-loading models to seamlessly integrate with your existing production layout.

- Unparalleled Efficiency: For the ultimate cutting speed and throughput, consider our innovative angular panel saw. This groundbreaking machine combines horizontal and vertical cutting in a single step, saving valuable floor space and maximizing production output.

Invest in Quality, Reap the Rewards:

Our CNC wood cutter machines are built to last, featuring:

- High-Strength Steel Construction: Ensuring exceptional durability and maintaining cutting accuracy over years of operation.

- Advanced Automation: Experience a user-friendly experience with cutting-edge software and automation features.

- Proven Reliability: We utilize a meticulous manufacturing process that guarantees reliable performance, keeping your production line running smoothly.

Elevate your wood wardrobe production today! Explore our diverse selection of CNC wood cutter machines and discover the perfect solution to revolutionize your material preparation process. Contact us to discuss your specific needs and let our experienced team guide you towards achieving optimal cutting efficiency. Together, let’s create high-quality wood wardrobes with cutting-edge technology.