Revolutionize LVL Processing: High-Quality CNC Saws from Your Leading Computerized Panel Cutter Machine Factory

Improve your woodworking projects with the power of Computerized Panel Cutter Machine (CNC Saw)

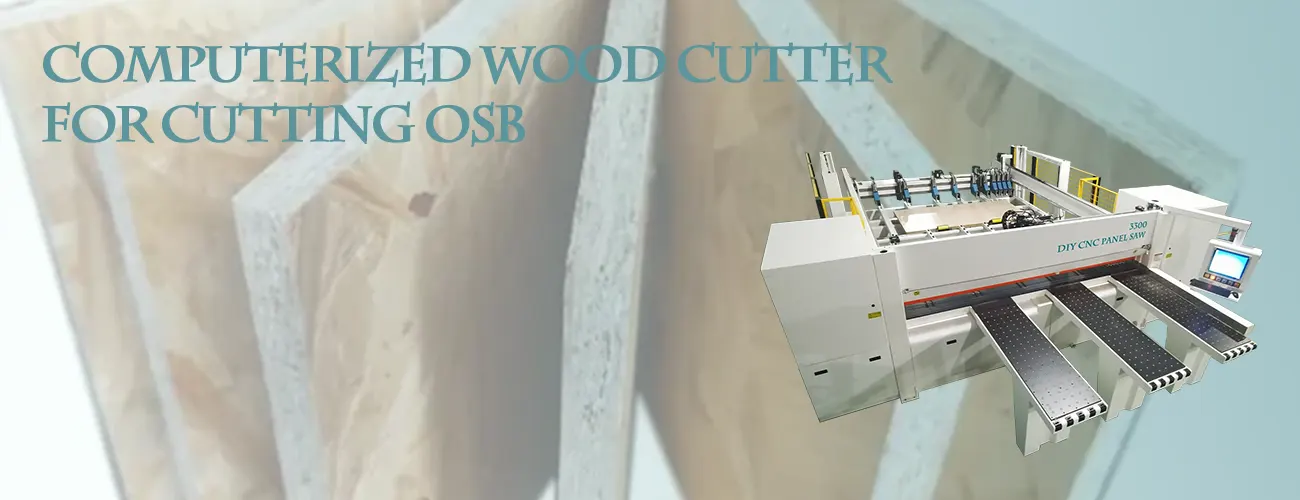

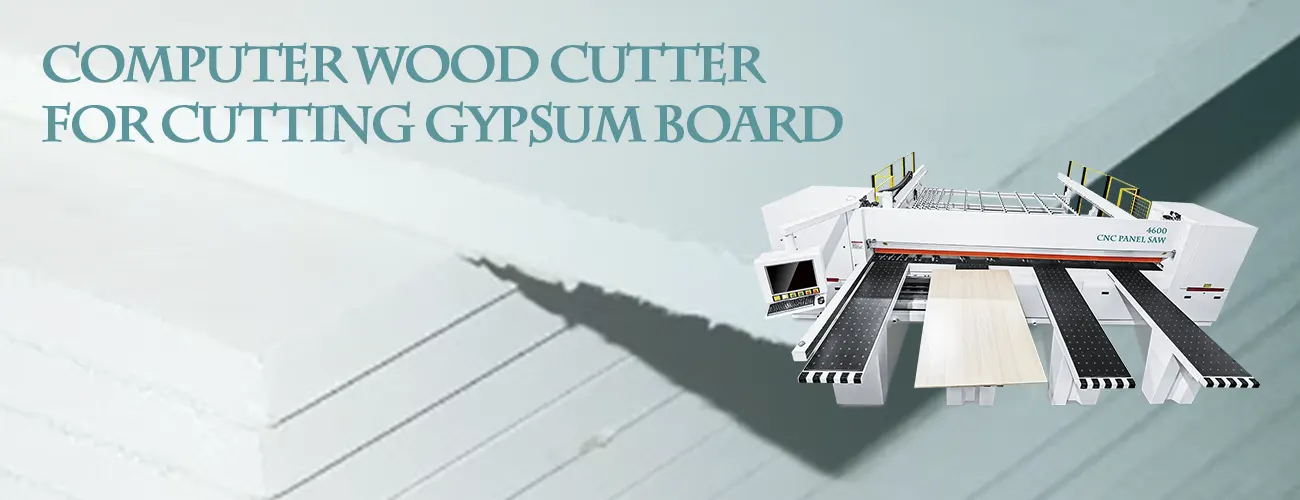

LVL (Laminated Veneer Lumber) is a high-strength engineered wood product gaining significant traction in construction applications. While traditional panel cutting saws might seem like a viable option, they often lack the precision and control needed to achieve clean, efficient cuts in LVL. Here’s where a computerized panel cutter machine (CNC saw) from a reputable factory like ours comes in, offering a superior solution for LVL sizing. CNC panel cutting machines are revolutionizing the woodworking industry, and for good reason.

What is LVL?

LVL is an engineered wood product composed of thin wood veneers bonded together with adhesive, typically in a layered formation with alternating grain directions. This unique construction process creates a strong, dimensionally stable material that offers distinct advantages over traditional solid wood. LVL is a preferred choice for various construction projects due to its:

- Superior Strength: The layered structure and alternating grain orientation provide exceptional strength and load-bearing capacity, making it ideal for beams, headers, and other structural applications.

- Dimensional Stability: LVL exhibits minimal shrinkage and warping compared to solid wood, making it ideal for applications requiring precise dimensions, such as door and window frames.

- Versatility: Available in various thicknesses and lengths, LVL can be used for a wide range of structural applications, from beams and headers to studs and trusses.

- Eco-Friendly Alternative: LVL utilizes smaller wood pieces, promoting efficient wood resource utilization and sustainability in construction projects.

Features of LVL:

- High Strength-to-Weight Ratio: LVL offers excellent strength without excessive weight, making it ideal for applications where weight reduction is crucial, such as floor joists and roof trusses.

- Uniformity: The controlled manufacturing process ensures consistent material properties throughout the LVL panel, guaranteeing reliable performance.

- Workability: LVL can be easily cut, drilled, and fastened using standard woodworking tools, making it a versatile material for construction projects.

- Moisture Resistance: Modern adhesives enhance the moisture resistance of LVL compared to traditional solid wood, making it suitable for some exterior applications.

How Computerized Panel Cutter Machines (CNC Saws) are Utilized in Cutting LVL?

Computerized panel cutter machines (CNC saws) revolutionize LVL processing by offering unparalleled precision and efficiency, empowering you to unlock the full potential of this versatile building material:

- Computer-Aided Design (CAD) Compatibility: Import your precise cutting plans directly into the CNC panel cutting machine’s software. This ensures every cut is accurate and repeatable, minimizing waste and maximizing material utilization. No more relying on manual measurements and potential human error, leading to consistent, high-quality results.

- Automated Cutting Processes: Eliminate manual cutting and its inherent potential for errors. Automated cutting with a CNC saw saves valuable time and ensures consistent, professional results, even for complex designs. This translates to increased productivity and efficiency in your LVL processing workflow.

- Variable Cutting Speeds and Depths: Precise control over cutting parameters allows for optimal results on various LVL thicknesses. This ensures clean cuts that minimize chipping and delamination of the layered structure, preserving the material’s strength and integrity.

- Dust Extraction Systems: Most computerized panel cutter machines come equipped with integrated dust extraction systems, promoting a clean and healthy work environment. This minimizes airborne particles during the cutting process, protecting both your health and the surrounding environment.

Advantages of Our High-Quality CNC Saws in Sizing LVL

Investing in a high-quality CNC panel cutting saw from our factory offers several advantages for LVL sizing, propelling your woodworking projects to the next level:

- Enhanced Precision: Achieve perfectly sized LVL components every time with computer-controlled accuracy. This eliminates human error and ensures seamless integration during construction, saving time and minimizing rework costs. CNC panel cutting saws guarantee precision cuts, leading to a professional finish in your projects.

- Increased Efficiency: Automated cutting processes significantly reduce production time compared to traditional panel cutting saws, allowing you to complete projects faster and meet deadlines efficiently. This translates to increased productivity and cost savings overall, making CNC saws a valuable investment for high-volume LVL processing.

- Reduced Material Waste: Optimized cutting layouts with CNC panel cutting machines minimize scrap material. This saves you money on LVL and minimizes environmental impact by promoting sustainable resource utilization. By maximizing material utilization, CNC saws contribute to a more eco-friendly woodworking process.

- Improved Workpiece Quality: Clean and precise cuts minimize damage to the layered structure of LVL, ensuring optimal strength and performance in the final application. This translates to structurally sound and long-lasting results in your construction projects.

- Simplified Workflows: User-friendly interfaces and automated features streamline the cutting process with CNC panel cutting machines. This frees you to focus on project management and assembly tasks, maximizing your time and resources. CNC saws empower a more efficient workflow in your LVL processing.

- Enhanced Safety: Automated cutting with CNC saws minimizes operator interaction with blades, enhancing safety in your workshop. This reduces the risk of accidents and ensures a safer working environment for everyone involved.

Invest in a Reliable Partner for Your LVL Cutting Needs

As a leading computerized panel cutter machine factory, we understand the importance of precision, efficiency, and safety in LVL processing. Our high-quality CNC panel cutting saws empower you to achieve superior results, optimize your workflow, and elevate your construction projects. Contact us today to learn more about how our CNC saws can revolutionize your approach to LVL cutting and unlock the full potential of this versatile building material!

Here at [Your Factory Name], we are committed to providing our customers with the latest advancements in CNC technology. We offer a wide range of CNC panel cutting machines to suit your specific needs and budget. Contact us today to discuss your LVL cutting requirements and experience the difference that CNC saws can make in your woodworking projects!