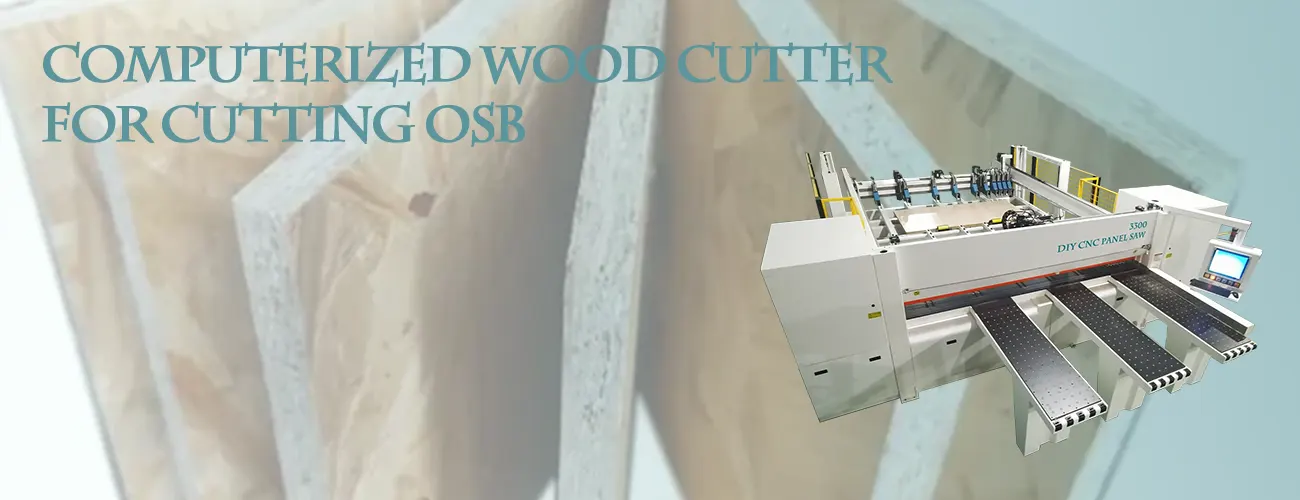

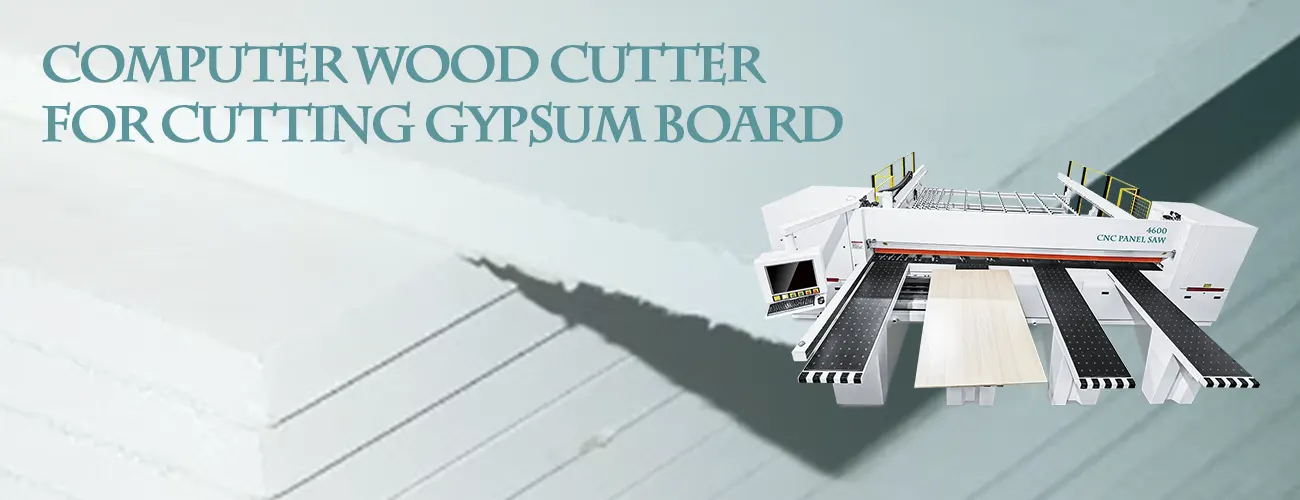

CNC Beam Saw Machines for Wood Wool Panel Processing

Improve your woodworking projects with the power of CNC Beam Saw Machine

Wood wool panels, a rapidly growing eco-friendly building material, offer a unique combination of sustainability, functionality, and aesthetics. However, achieving clean and precise cuts in this versatile yet delicate material requires specialized equipment. This is where CNC beam saw machines come into play. As a leading manufacturer of innovative cutting machinery, we offer advanced automatic beam saws and flexible beam saws specifically designed for efficient and accurate processing of wood wool panels, elevating your commitment to sustainable construction practices.

What is a Wood Wool Panel?

Wood wool panels are prefabricated building components composed primarily of thin, shredded wood strands bonded with a natural or synthetic binder. These panels offer a viable alternative to traditional materials like plywood or gypsum board while promoting eco-friendly construction practices.

Features of Wood Wool Panels:

- Sustainability: Wood wool panels utilize recycled wood waste, minimizing environmental impact and promoting the use of renewable resources.

- Thermal and Acoustic Insulation: The air trapped within the wood wool fibers provides excellent thermal and acoustic insulation properties, contributing to energy efficiency and soundproofing in buildings.

- Fire Resistance: Many wood wool panels offer inherent fire resistance properties, enhancing building safety.

- Breathability: Wood wool panels allow for natural vapor diffusion, helping regulate indoor humidity and creating a healthier living environment.

- Lightweight and Versatile: Wood wool panels are lightweight and easy to handle while offering good structural integrity. They can be used for various applications in building construction.

How CNC Beam Saw Machines (Automatic Beam Saws and Flexible Beam Saws) are Utilized in Cutting Wood Wool Panel

CNC beam saw machines, encompassing both automatic beam saws and flexible beam saws, are specifically designed for efficient and precise cutting of large sheet materials like wood wool panels. Here’s how these advanced machines excel in handling this eco-friendly building material:

- Industrial-Grade Saw Blades with Specialized Designs: CNC beam saw machines utilize high-quality saw blades specifically designed for cutting wood wool panels. These blades minimize dust generation and chipping, ensuring clean and precise cuts that preserve the integrity of the delicate wood wool fibers.

- Computerized Numerical Control (CNC): Advanced CNC beam saw machines incorporate CNC technology. This allows for precise programming of cutting paths. Complex shapes or intricate designs for walls, ceilings, or custom acoustic panels can be programmed with ease and repeatedly cut with unparalleled accuracy for your wood wool panel projects.

- Vacuum Clamping Systems: Many CNC beam saw machines integrate vacuum clamping systems. This ensures that the wood wool panel sheet remains securely fixed during the cutting process, preventing movement or vibration that could damage the material or compromise cutting accuracy.

- Dust Extraction Systems: Integrated dust extraction systems effectively capture dust particles generated during cutting. This maintains a clean working environment for operators, minimizes the risk of respiratory irritation, and allows for better visibility during cutting operations, crucial for achieving precise results with wood wool panels.

- Automatic Tool Change Systems (For Select Models): Some advanced CNC beam saw machines, particularly automatic models, boast automatic tool change systems. This allows for seamless switching between cutting blades and scoring discs, optimizing the cutting process for clean and chip-free edges on wood wool panels.

- Flexible Cutting Capabilities (For Select Models): Flexible beam saws, a specific type of CNC beam saw machine, offer additional functionalities. These saws incorporate a movable saw carriage that can tilt or rotate on multiple axes. This allows for angled cuts, bevels, and even complex curved shapes on wood wool panels, expanding design possibilities for creative applications.

Advantages of Our CNC Beam Saw Machines (Automatic Beam Saws and Flexible Beam Saws) in Sizing Wood Wool Panel

Choosing a CNC beam saw machine, whether an automatic beam saw or a flexible beam saw, from our company offers several advantages for efficient and precise sizing of wood wool panels:

- Superior Cutting Performance: Our industrial-grade machines ensure clean and accurate cuts, minimizing material waste and preserving the integrity of your wood wool panels. This translates to professional-looking finished parts with minimal rework required, saving you time and resources on your sustainable construction projects.

- Enhanced Production Efficiency: The automation, precision, and advanced features of our CNC beam saw machines significantly reduce cutting times compared to manual methods. This translates to faster project completion, improved production throughput, and increased productivity for your wood wool panel processing.

- Reduced Material Waste: Precision cutting systems and optimized processes with automatic tool changes (on select models) minimize scrap material, allowing you to optimize the use of your wood wool panels. This not only reduces material costs but also aligns with responsible resource management practices in the construction industry.

- Versatility for Diverse Applications: Our CNC beam saw machines can handle various wood wool panel sizes, thicknesses, and densities. They can also navigate intricate shapes and complex designs with ease. This versatility makes them suitable for a wide range of applications in sustainable construction projects, including:

- Wall and Ceiling Systems: CNC beam saw machines ensure precise cutting of wood wool panels for walls and ceilings. Clean cuts and a smooth finish contribute to a modern aesthetic and efficient installation in residential or commercial buildings.

- Acoustic Panels: The sound absorption properties of wood wool make it ideal for acoustic panels. CNC beam saws, particularly those with flexible cutting capabilities, allow for precise cutting of custom shapes and intricate designs for effective acoustic dampening solutions.

- Non-Load Bearing Interior Partitions: Wood wool panels, due to their lightweight nature and good structural integrity, are suitable for non-load-bearing interior partitions. CNC beam saws ensure accurate cuts for a seamless and visually appealing finish.

- Sustainable Furniture Design: Wood wool panels can be incorporated into sustainable furniture design elements. CNC beam saws enable precise cutting of components for eco-friendly furniture pieces or custom decorative elements.

- Proven Reliability – Built on Decades of Expertise: As a leading manufacturer of innovative cutting machinery, we possess extensive experience in crafting reliable and high-performance CNC beam saw machines. Our saws are renowned for their durability, minimal maintenance requirements, and long-lasting performance. This translates to a reliable production tool you can depend on for years of efficient and sustainable wood wool panel processing on your construction projects.

Creative Potential of CNC Beam Saw Machines

While efficiency remains a critical aspect, CNC beam saw machines offer more than just fast and precise cutting for wood wool panel processing. These machines unlock a world of creative possibilities in sustainable construction:

- Complex Design Fabrication: The precise cutting capabilities and, in some models, the flexible cutting functionalities of CNC beam saw machines empower the creation of intricate design elements and bespoke architectural features from wood wool panels. This opens doors for innovative and visually striking wall or ceiling designs, or even custom acoustic panel configurations for various applications.

- Customization and Personalization: CNC beam saws allow for precise cutting of custom shapes and features, enabling the creation of personalized design elements for wood wool panels. This could include ventilation grilles with unique patterns or decorative cutouts for a touch of individuality in sustainable building projects.

- Integration with Sustainable Construction Techniques: CNC beam saw machines can be seamlessly integrated into a broader sustainable construction workflow. Precisely cut wood wool panel components can be further joined using techniques like natural adhesives or eco-friendly fasteners, creating complex and functional building elements with minimal environmental impact.

Investing in the Future of Sustainable Construction with Wood Wool Panels

By incorporating a CNC beam saw machine (automatic beam saw or flexible beam saw) from our leading company, you gain a powerful tool for efficient, precise, and versatile processing of wood wool panels. Our advanced machines not only improve your construction project workflow and minimize waste but also unlock a world of creative possibilities for your sustainable building endeavors. Contact us today to learn more about how our cutting-edge technology can revolutionize your approach to wood wool panel processing and empower you to bring your eco-friendly construction visions to life.