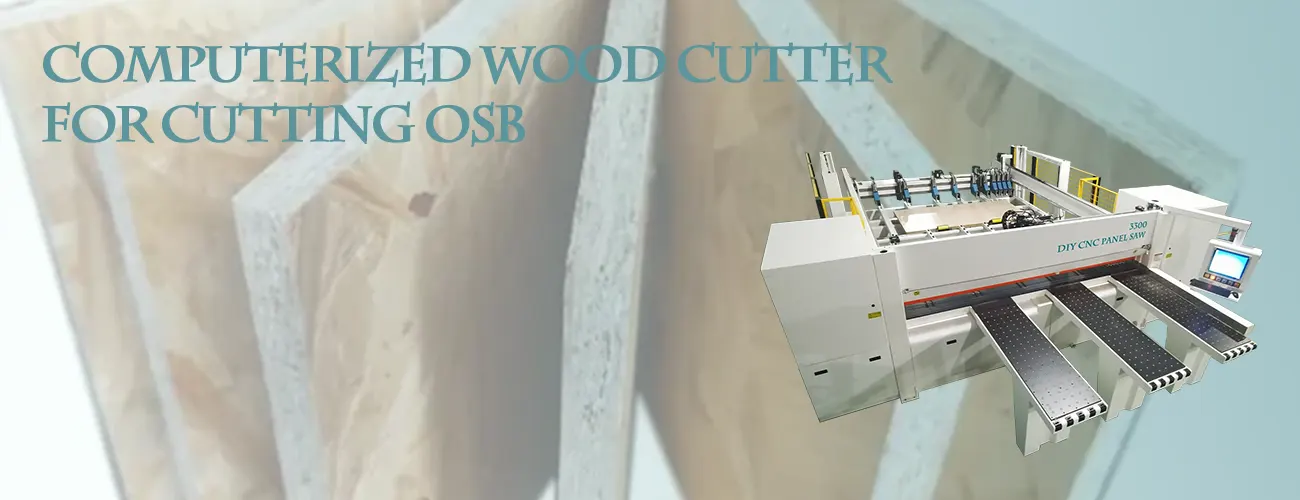

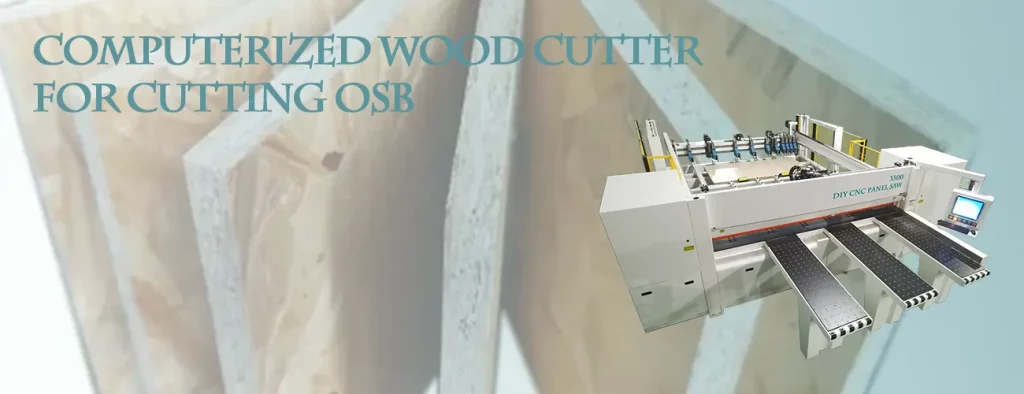

Unleash Efficiency: Computerized Wood Cutter Optimizes OSB Cutting

Improve your woodworking projects with the power of CNC technology.

OSB (Oriented Strand Board) is a versatile and cost-effective wood panel product widely used in construction projects. However, traditional cutting methods for OSB can be time-consuming, labor-intensive, and prone to errors. These inefficiencies can translate to wasted materials, increased project timelines, and potential safety hazards. Here’s where a computerized wood cutter steps in, offering a revolutionary approach to OSB processing, optimizing efficiency, and boosting overall project success.

What is OSB?

OSB is an engineered wood product composed of wood strands strategically oriented and bonded with resin. This strategic orientation creates a strong and dimensionally stable panel, offering several advantages over traditional solid wood options. OSB is a popular choice in construction applications due to its:

- Affordability: Compared to solid wood, OSB offers a more budget-friendly option for construction projects.

- Strength and Stability: The strategic orientation of wood strands provides good structural performance, making it suitable for load-bearing applications.

- Moisture Resistance: OSB offers improved moisture resistance compared to traditional particle board, making it suitable for use in exterior walls and roof sheathing.

- Versatility: Available in various thicknesses and panel sizes to meet diverse construction needs, from wall sheathing to subflooring and furniture components.

Beyond the Basics: Unveiling the Potential of OSB with Computerized Cutting

The benefits of OSB extend far beyond its core functionalities. With the precision and flexibility offered by computerized wood cutters, OSB can be transformed into a variety of unique design elements, pushing the boundaries of construction and design. Here are some examples:

- Curved Wall Features: Computerized wood cutters allow for the creation of curved wall features using OSB, adding a touch of modern elegance to interior spaces.

- Customizable Built-Ins: Precise cutting enables the creation of custom-designed built-in shelves, cabinets, and other storage solutions, maximizing space utilization and adding a touch of personalization to any room.

- Geometric Design Elements: OSB panels can be cut into intricate geometric shapes to create decorative wall panels, headboards, or architectural accents, adding visual interest and a unique touch to your design.

How Computerized Wood Cutter is Utilized in Cutting OSB?

Computerized wood cutters, also known as automatic wood cutting machines (maquina cortadora), transform OSB processing by offering a multitude of benefits:

- Computer-Aided Design (CAD) Compatibility: Import your precise cutting plans directly into the machine’s software. This ensures every cut is accurate and repeatable, minimizing waste and maximizing material utilization. No more relying on manual measurements and potential human error.

- Automated Cutting Processes: Eliminate manual cutting and its inherent potential for error. Automated cutting with a computerized wood cutter saves valuable time and ensures consistent, professional results, even for complex designs.

- Variable Cutting Speeds and Depths: Precise control over cutting parameters allows for optimal results on various OSB thicknesses. This ensures clean cuts that minimize chipping and damage to the material, reducing the need for post-cutting finishing.

- Dust Extraction Systems: Most computerized wood cutters come equipped with integrated dust extraction systems, promoting a clean and healthy work environment. This minimizes airborne particles during the cutting process, protecting both your health and the surrounding environment.

Advantages of Our Computerized Wood Cutter in Sizing OSB

Investing in a computerized wood cutter for your OSB cutting needs offers several advantages:

- Enhanced Precision: Achieve perfectly sized OSB panels every time with computer-controlled accuracy. This eliminates human error and ensures seamless installation during construction, saving time and minimizing rework.

- Increased Efficiency: Automated cutting processes significantly reduce production time compared to manual methods, allowing you to complete projects faster and meet deadlines efficiently. This translates to increased productivity and cost savings overall.

- Reduced Material Waste: Optimized cutting layouts with computerized wood cutters minimize scrap material. This saves you money on materials and minimizes environmental impact by promoting sustainable resource utilization.

- Simplified Workflows: User-friendly interfaces and automated features streamline the cutting process. This frees you to focus on project management and assembly tasks, maximizing your time and resources.

- Improved Safety: Automated cutting minimizes operator interaction with blades, enhancing safety in your workshop. This reduces the risk of accidents and ensures a safer working environment for everyone involved.

Invest in a Smarter Approach to OSB Cutting

Upgrade your OSB cutting processes with a computerized wood cutter. Our machines offer unmatched precision, efficiency, and safety, empowering you to take your construction projects to the next level. Contact us today to learn more about how a computerized wood cutter can revolutionize your approach to OSB processing!