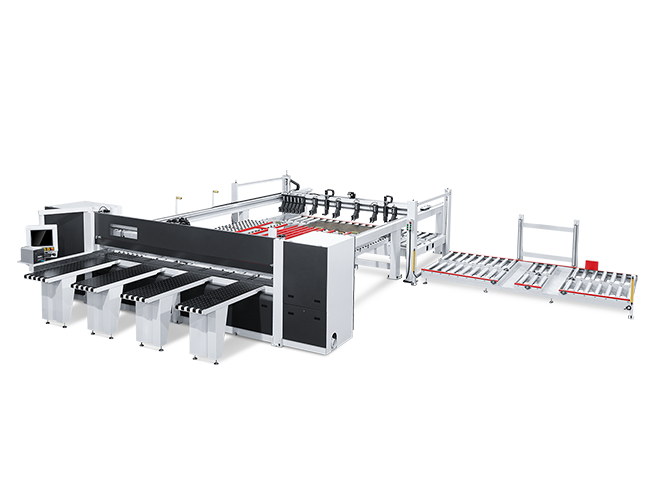

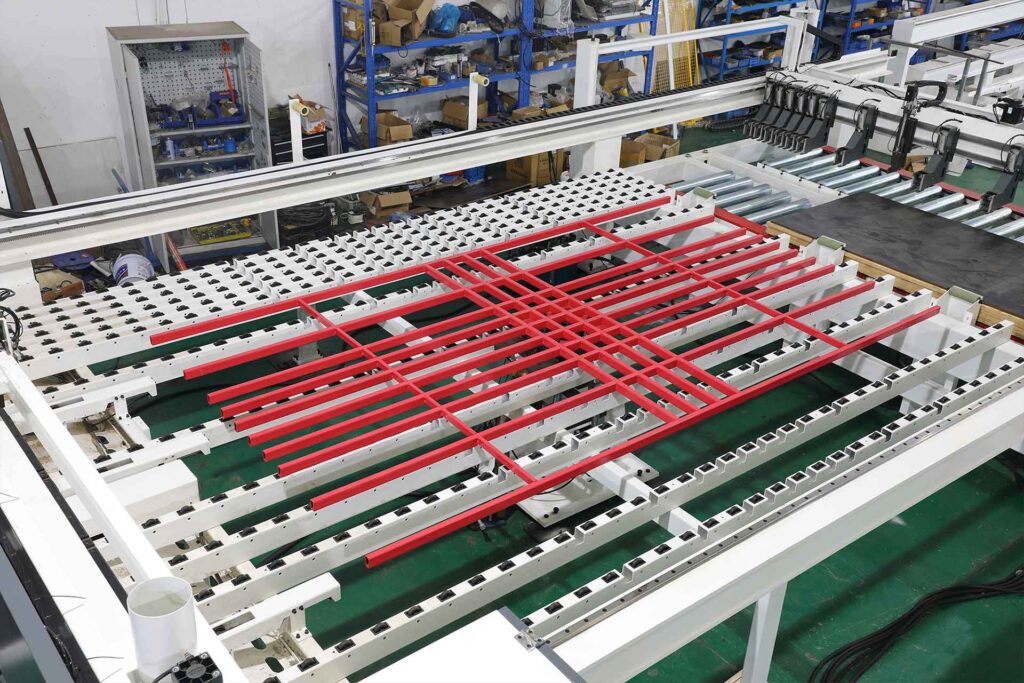

Innovative Design of Back Rotation

Innovative back rotation platform design, highly improve the meterial ultilization rate.

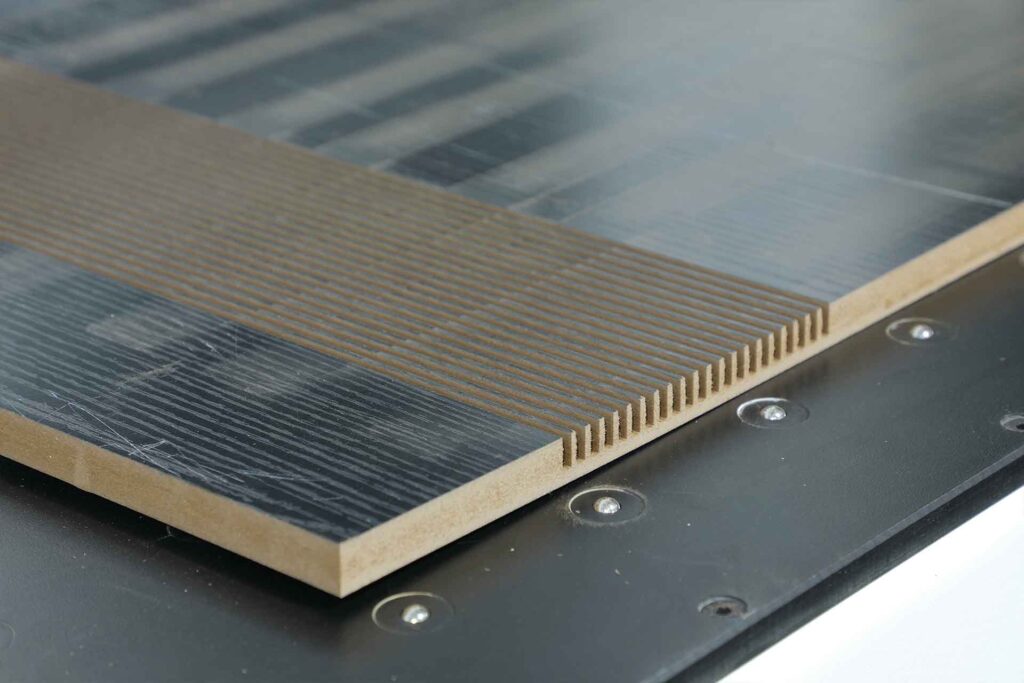

Servo controled large saw blade

Sawing height precision reaches ±0.1mm, suitable for the process of kitchen and wardrobe corner arc, etc.

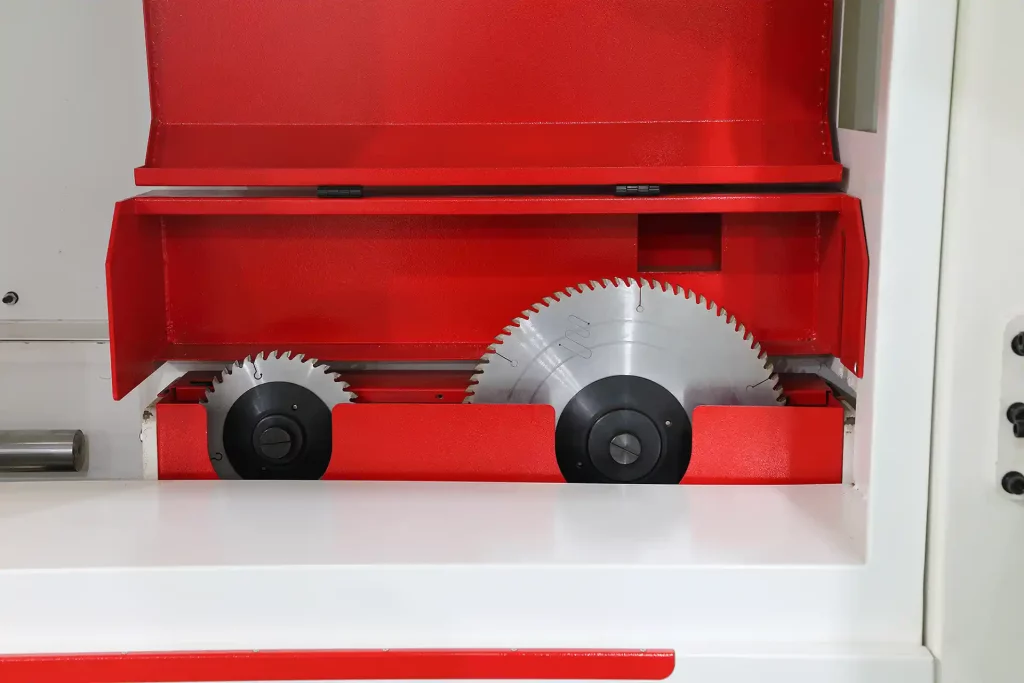

Large and Small Saw with Separate Structures

This configuration offers optimal cutting performance for various material thicknesses.

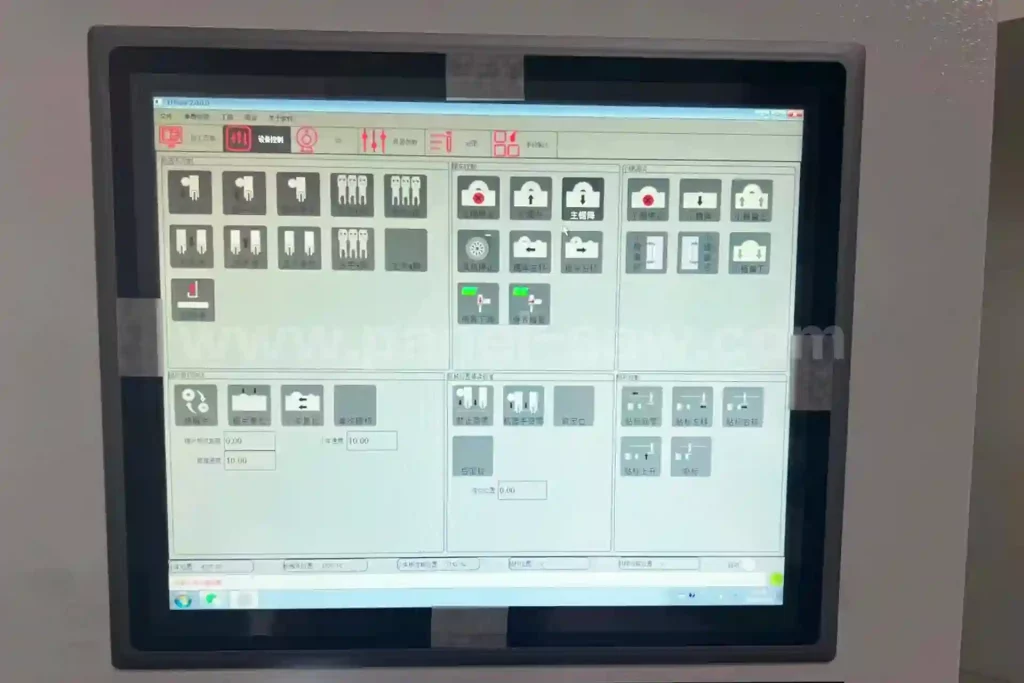

Professional industrial computer

Clear and easy-to-understand interface, automatic optimization, efficient production