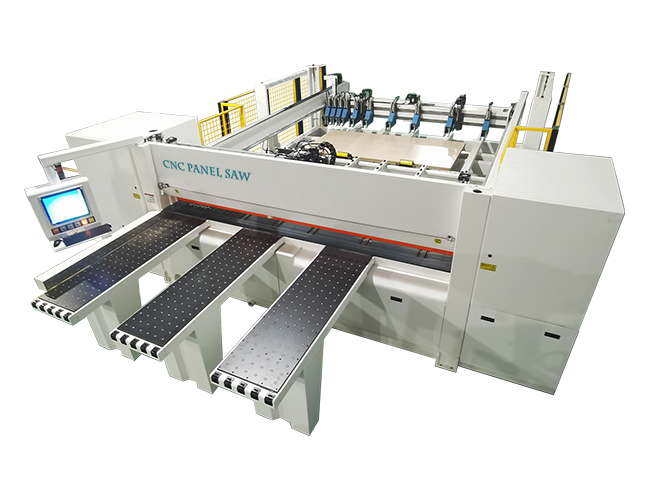

The manufacturing of our rear loading CNC beam saws follows a precise and robust process to ensure quality and durability. The first step is custom designing the panel saw structure based on customer specifications. This is followed by the preparation of high-strength steel, which is then cut to size. After the steel cutting phase, the framework undergoes welding and annealing processes to ensure structural integrity. Machining is done to fine-tune the frame, followed by another welding step to finalize the structure. The framework is then painted to protect it from wear and corrosion. In parallel, other sheet metal components such as the panel pressing beam and manipulator beams are shaped and surface-treated through methods like phosphating, powder coating, or painting.

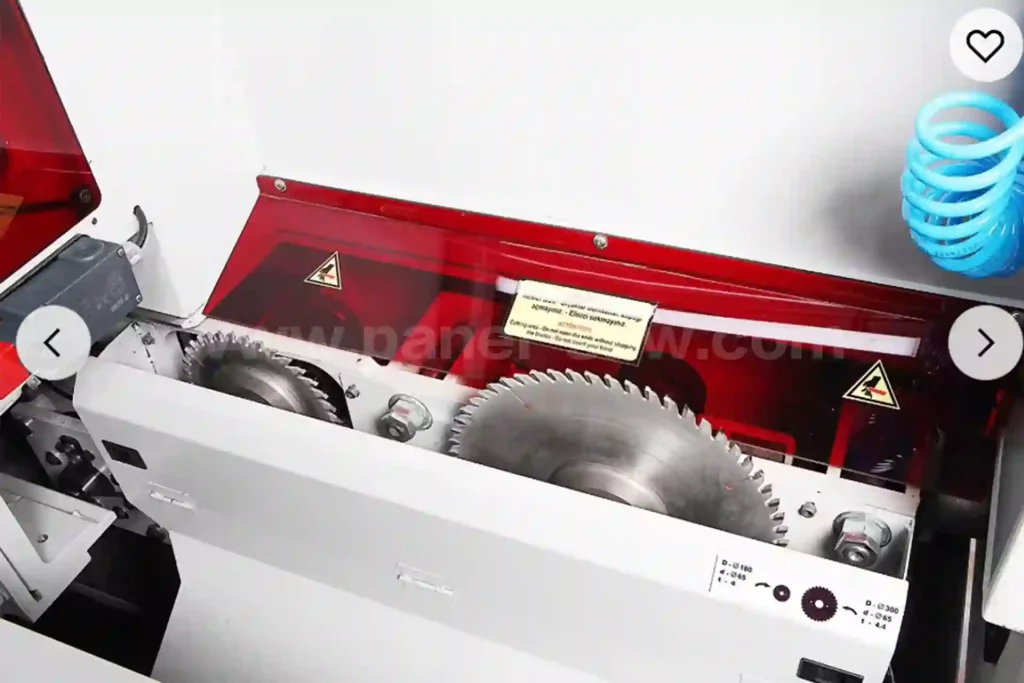

Once all mechanical components are ready, the electrical parts and software systems are integrated. This includes assembling the saw motors, sensors, and control systems. Finally, the machine undergoes software preparation and commissioning to ensure all functions are operating smoothly. Once all these steps are completed, the computer beam saw is fully assembled, tested, and ready for customer use. This meticulous process ensures each CNC beam saw meets the highest standards of quality and performance.

The manufacturing process of our CNC saw machines involves several meticulous steps to ensure top-notch quality and performance:

- Custom Designing: The panel saw structure and other components are custom-designed to meet specific requirements.

- High Strength Steel Preparation: High-quality steel is prepared to ensure durability and strength.

- Steel Cutting: Precise cutting of steel to form the framework and other essential parts.

- Welding: Robust welding processes to assemble the structure securely.

- Annealing: Heat treatment to relieve stress and enhance material properties.

- Machining: Precision machining to achieve the required dimensions and tolerances.

- Welding (Again): Additional welding for any secondary components or reinforcements.

- Painting: High-quality painting or coating to protect against corrosion and wear.

For other sheet metal parts like the panel pressing beam and beams with manipulators, the following steps are undertaken:

– Precision Shaping: Parts are processed and shaped according to precise drawings.

– Surface Treatment: Includes phosphating, powder coating, or painting for enhanced durability.

Finally, all electrical parts and accessories are prepared, followed by the final assembly. The software is then installed and the machine is commissioned to ensure everything is functioning perfectly. This comprehensive manufacturing procedure guarantees a high-quality computer wood saw ready for our customers.