Stable clamping with 12 sets of clamps

12 sets of clamps, stable clamping, servo control and precise material pushing

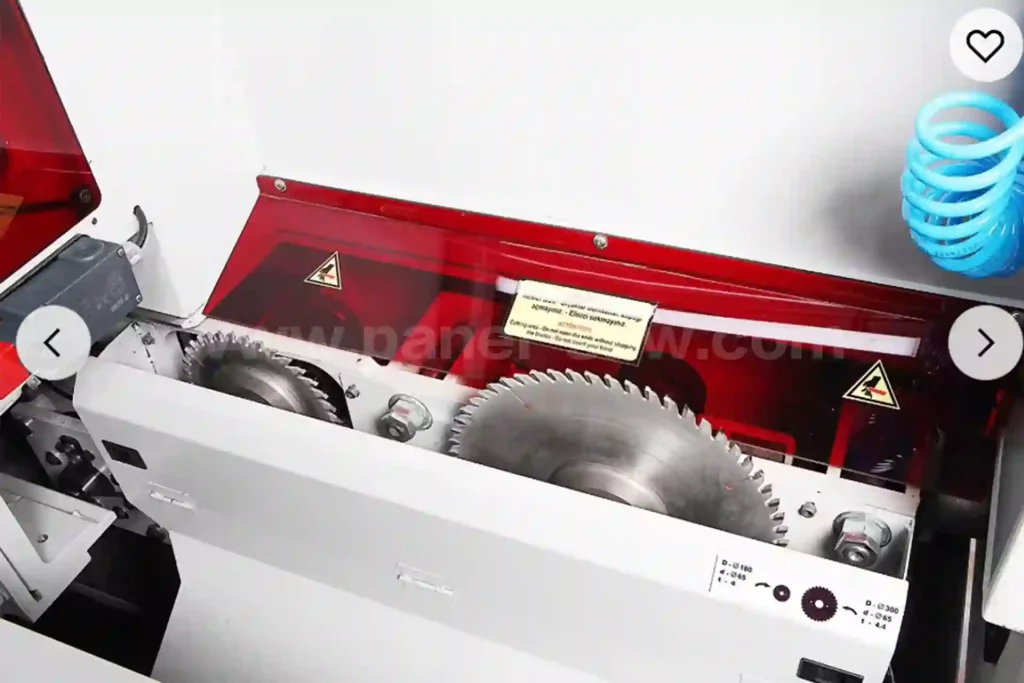

German-type Saw Shaft:

This high-quality saw shaft ensures clean and precise cuts.

Large and Small Saw with Separate Structures

This configuration offers optimal cutting performance for various material thicknesses.

Double pushing beams mechanism

One pushing beam for panel boards loading, one pushing beam for feeding boards. Automatic and high efficient