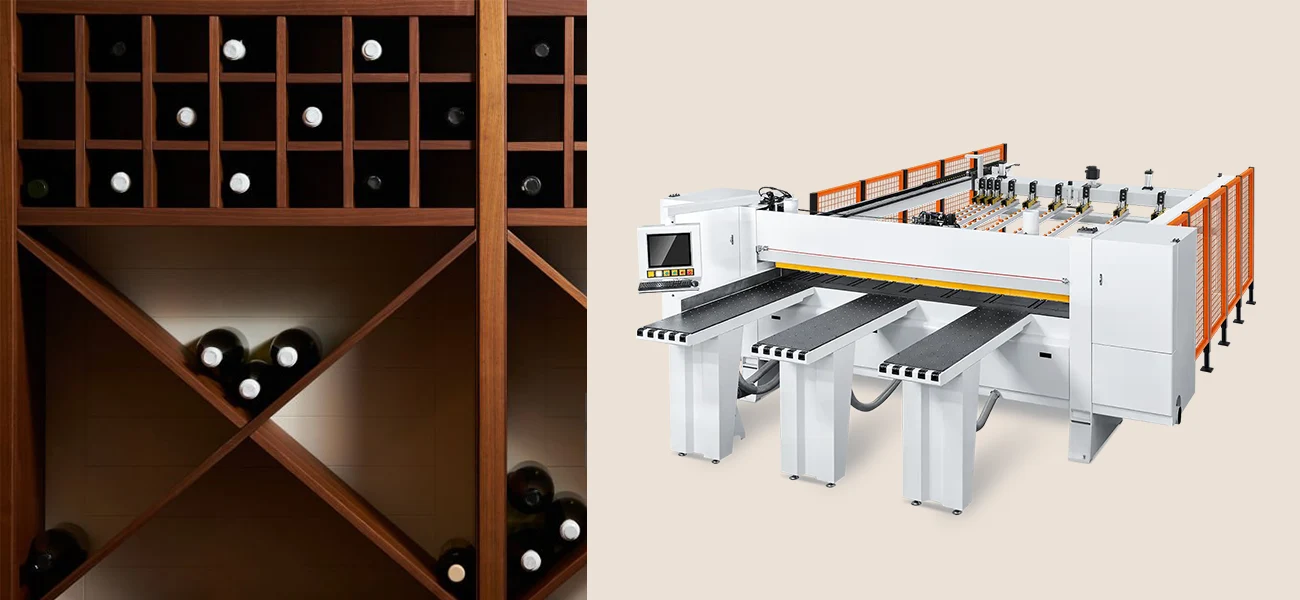

Support Your Office Furniture Production: Powerful Industrial Panel Saws from the Original Manufacturer

Streamline your wooden office furniture production with high-performance industrial panel saws from our factory. We understand the importance of efficiency and precision in every stage of furniture making, particularly during material preparation, the first and critical step in production.

From Blueprint to Boardroom: The production process of Office Furniture

The magic of transforming raw materials into functional and stylish office furniture involves a captivating journey. Here’s a breakdown of the key stages:

- Design and Engineering: The process begins with brainstorming creative ideas. Designers translate these concepts into detailed blueprints, taking into account ergonomics, aesthetics, and functionality. Engineers then meticulously plan the construction process, ensuring structural integrity and efficient material usage.

- Prototyping: Before large-scale production commences, a prototype is often created. This physical model allows for design refinement, testing functionality, and identifying any potential issues before full production.

- Production: The Heartbeat of Manufacturing

Production is the bustling center of furniture creation, involving several crucial steps:

- Material Preparation: Raw materials like wood, metal, or fabric are meticulously cut, shaped, and sanded according to pre-defined specifications. This stage sets the foundation for every piece.

- Assembly: Skilled workers or automated machinery bring the components together, assembling the furniture based on the technical drawings. Legs, frames, and hardware are meticulously attached to create the final structure.

- Finishing: A touch of artistry! Here, the furniture is adorned with a protective and aesthetically pleasing finish. Paint, varnish, or stain are applied, enhancing the visual appeal and durability of each piece.

- Quality Control: Trained inspectors ensure every piece meets stringent quality standards. Visual inspections, functionality tests, and even load-bearing tests are conducted to guarantee the furniture is safe, functional, and built to last.

- Packaging and Shipping: Once deemed flawless, the furniture is carefully packaged to prevent damage during transportation. It then embarks on its journey to distributors, retailers, or directly to customers.

- After-Sales Service: The commitment often extends beyond delivery. Some manufacturers offer after-sales services like installation, repair, or replacement of defective parts, ensuring customer satisfaction and maintaining a strong reputation.

This glimpse into the captivating journey showcases the intricate processes that transform raw materials into the furniture that graces our offices, fostering productivity and comfort in the workplace.

Industrial Panel Saws: The Cutting Edge of Efficiency

Our industrial panel saws play a pivotal role in your office furniture production process. Here’s how they empower you:

- Unmatched Precision: Computer-controlled cutting ensures every board is sized to exact specifications, minimizing material waste and maximizing production yield.

- Streamlined Workflow: Automated cutting processes eliminate manual operations, saving time and labor costs.

- Unparalleled Efficiency: Intelligent software optimizes cutting layouts to minimize scrap and maximize material utilization.

- Reduced Errors: Automated processes minimize human error, leading to consistent quality and fewer production delays.

- Proven Performance: Our industrial panel saws boast a long history of reliable operation in demanding furniture manufacturing environments.

Finding the Perfect Fit: A Range of Panel Saw Options

We understand that furniture makers have diverse needs. That’s why we offer a variety of industrial panel saw models to suit your specific production requirements:

- Cutting Capacity: Choose from sizes including 2800mm, 3300mm, 3800mm, 4200mm, and 4600mm to accommodate your typical office furniture panel dimensions.

- Loading Style: Select between front-loading and back-loading models to fit your workflow preferences.

- Ultimate Efficiency: For the most efficient cutting solution, consider our innovative angular panel saw. This groundbreaking machine combines horizontal and vertical cutting in one step, maximizing throughput and saving valuable floor space.

Invest in Quality, Reap the Rewards:

Our industrial panel saws are built to last, featuring:

- High-Strength Steel Construction: Ensuring long-lasting durability and maintaining cutting accuracy over time.

- Advanced Automation: Experience seamless user experience with cutting-edge software and automation features.

- Proven Reliability: We utilize a meticulous manufacturing process that guarantees reliable performance, keeping your production running smoothly.

Elevate your office furniture production today! Explore our range of industrial panel saws for sale and discover the perfect solution to revolutionize your material preparation process. Contact us to discuss your specific needs and let our experienced team guide you towards achieving optimal cutting efficiency. Together, let’s create high-quality office furniture with maximum efficiency.