The Benefits of Smart Factories for Furniture and Cabinet Shops

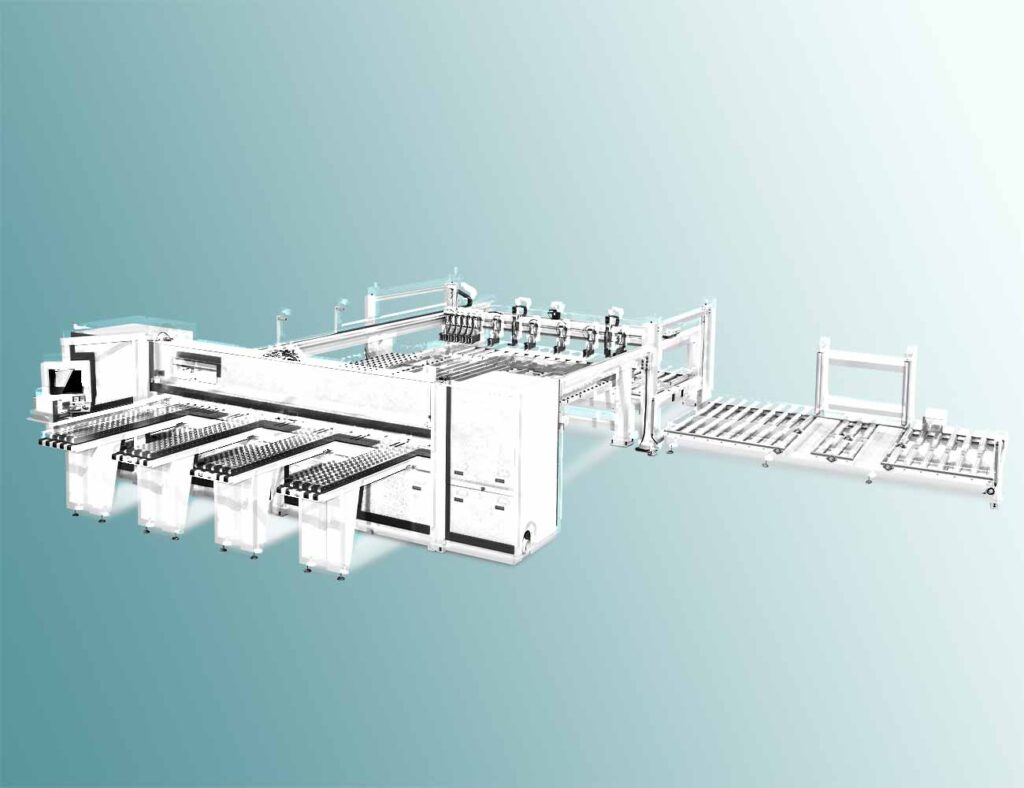

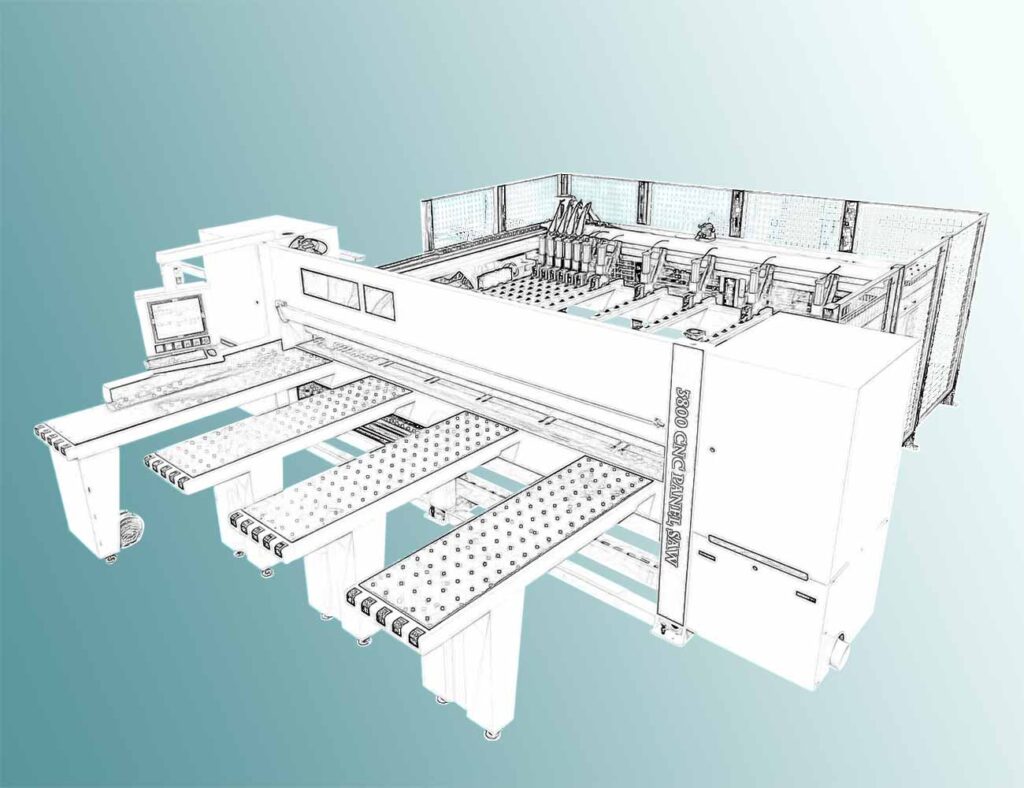

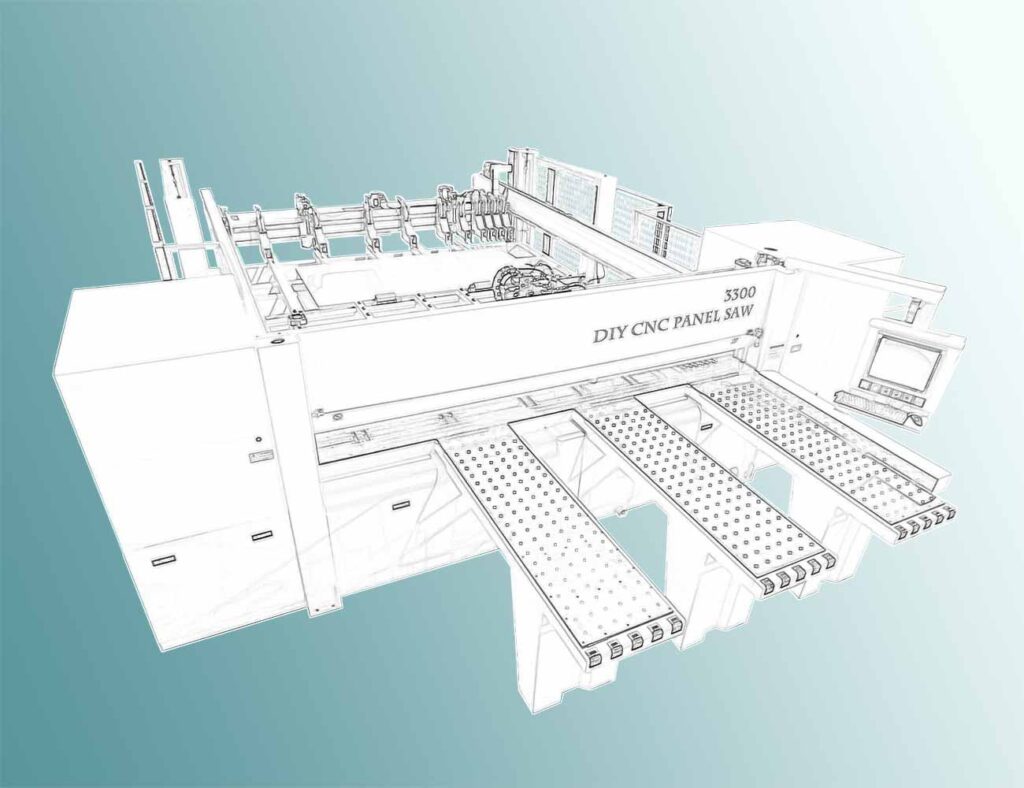

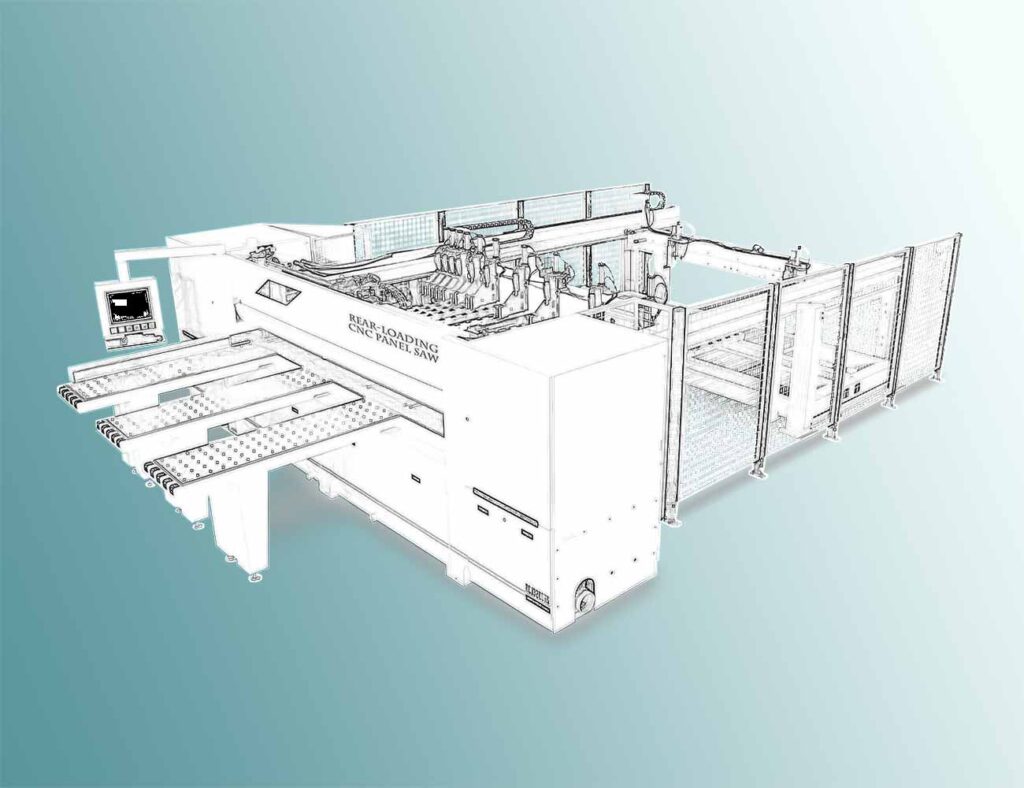

- Increased Efficiency: Smart factories streamline production processes, reducing manual labor and minimizing bottlenecks. This leads to increased output and faster turnaround times.

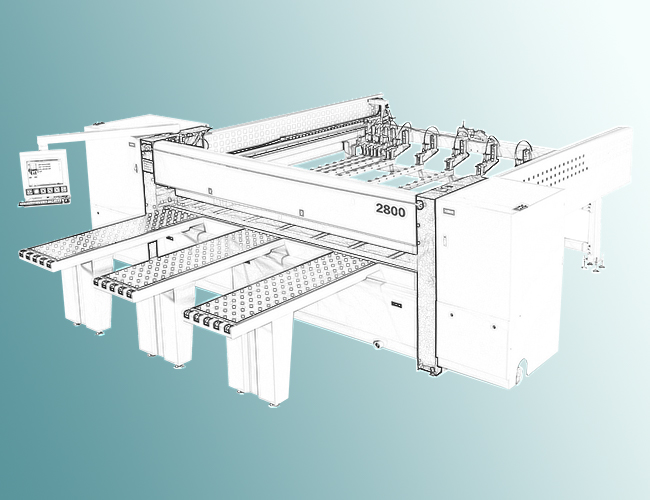

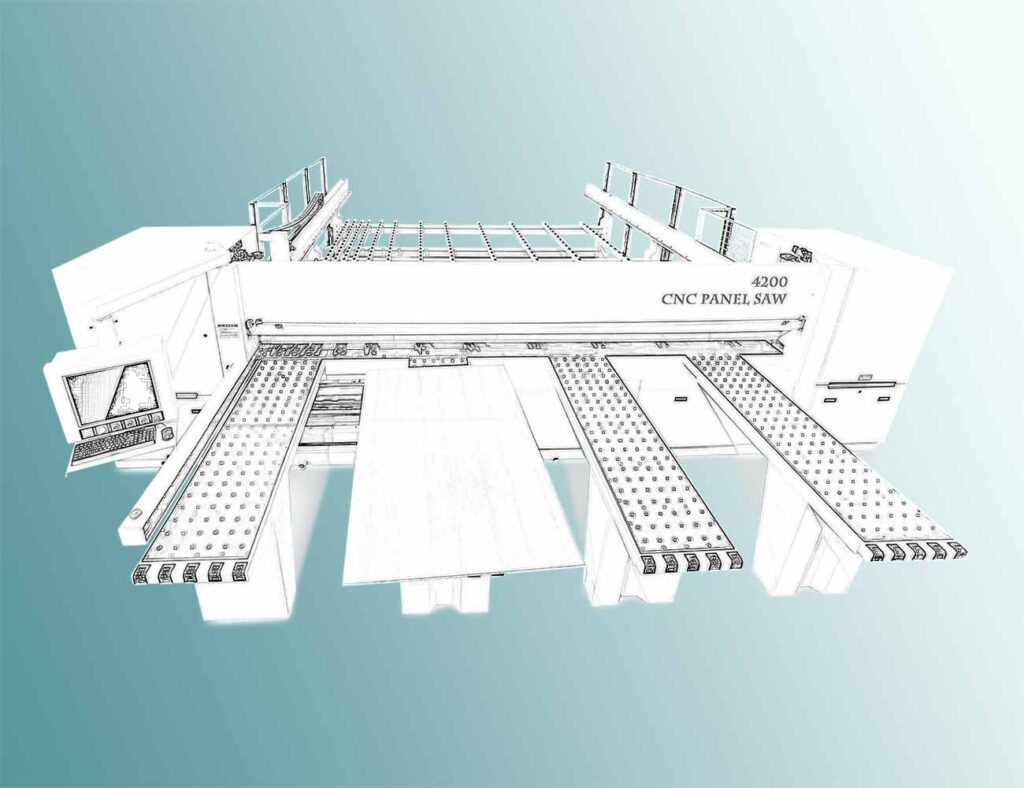

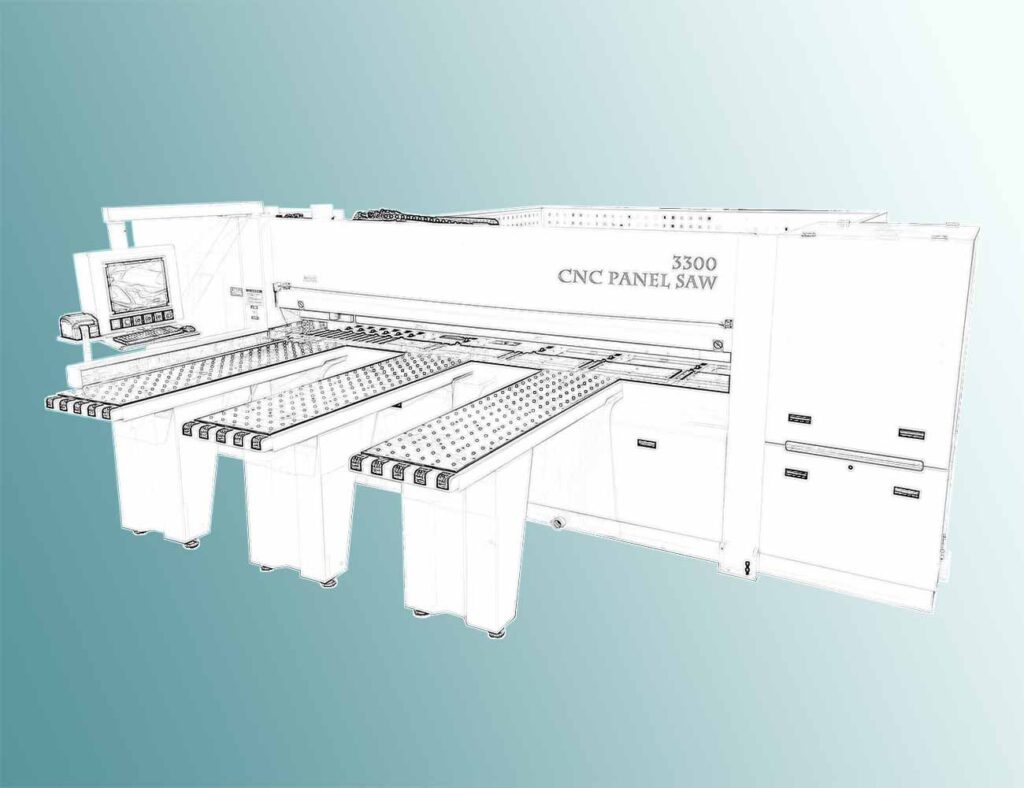

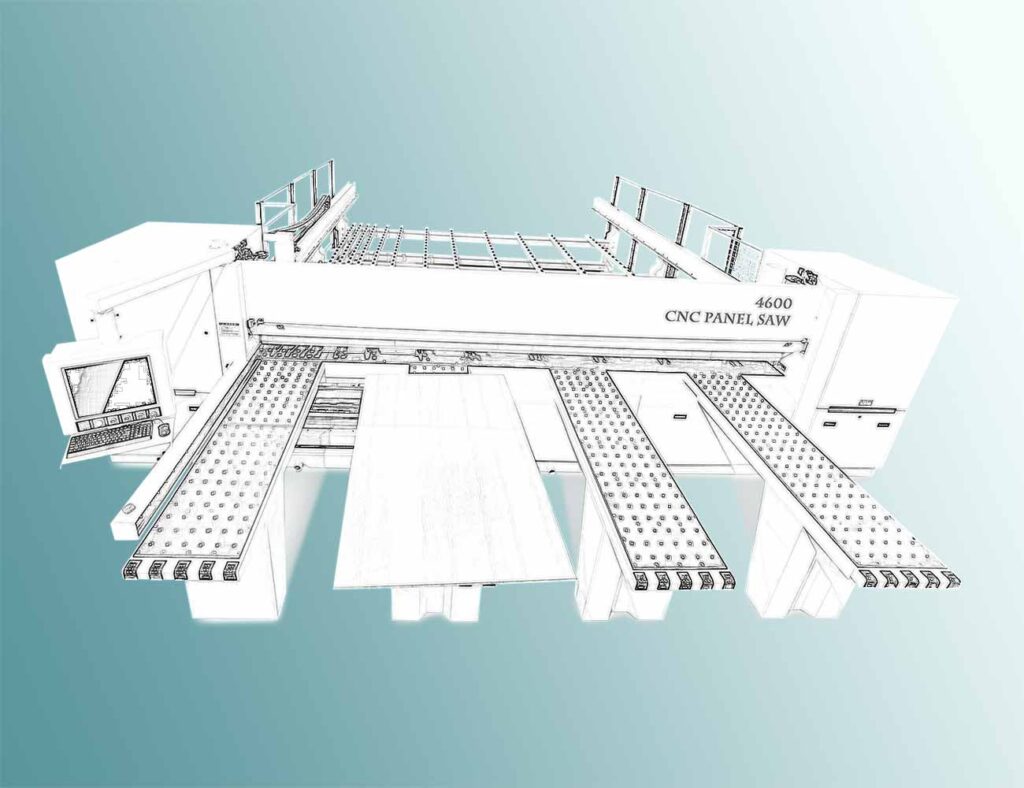

- Improved Quality: CNC machines ensure precise and consistent cuts, reducing errors and improving the overall quality of furniture and cabinets.

- Enhanced Flexibility: Smart factories can easily adapt to changing production requirements, allowing for customization and flexibility in product design.

- Cost Reduction: Automation can help reduce labor costs and material waste, leading to improved profitability.

- Improved Safety: By automating repetitive and hazardous tasks, smart factories can create a safer working environment for employees.