Front Loading Beam Saws mainly differs due to the cutting size of the materials

All Models of Front Loading Beam Saws

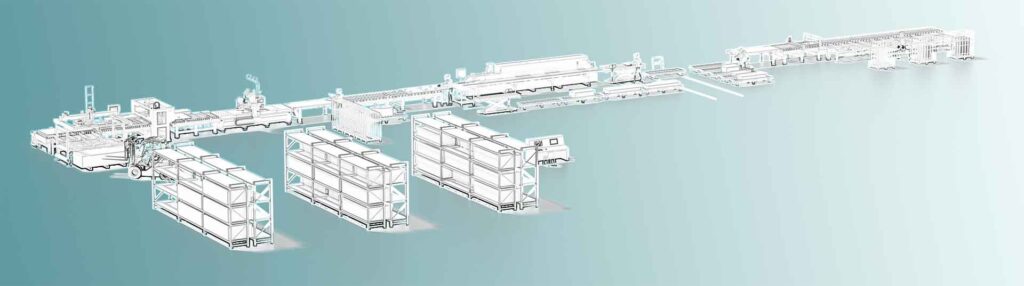

Customized beam machines for cutting large panel sizes

Front Loading Beam Saws are the most commonly used wood cutting machines. We have all models and sizes of front loading beam saws for sale with competitive price and quality. Conact now for getting beam machines quotation for your business.

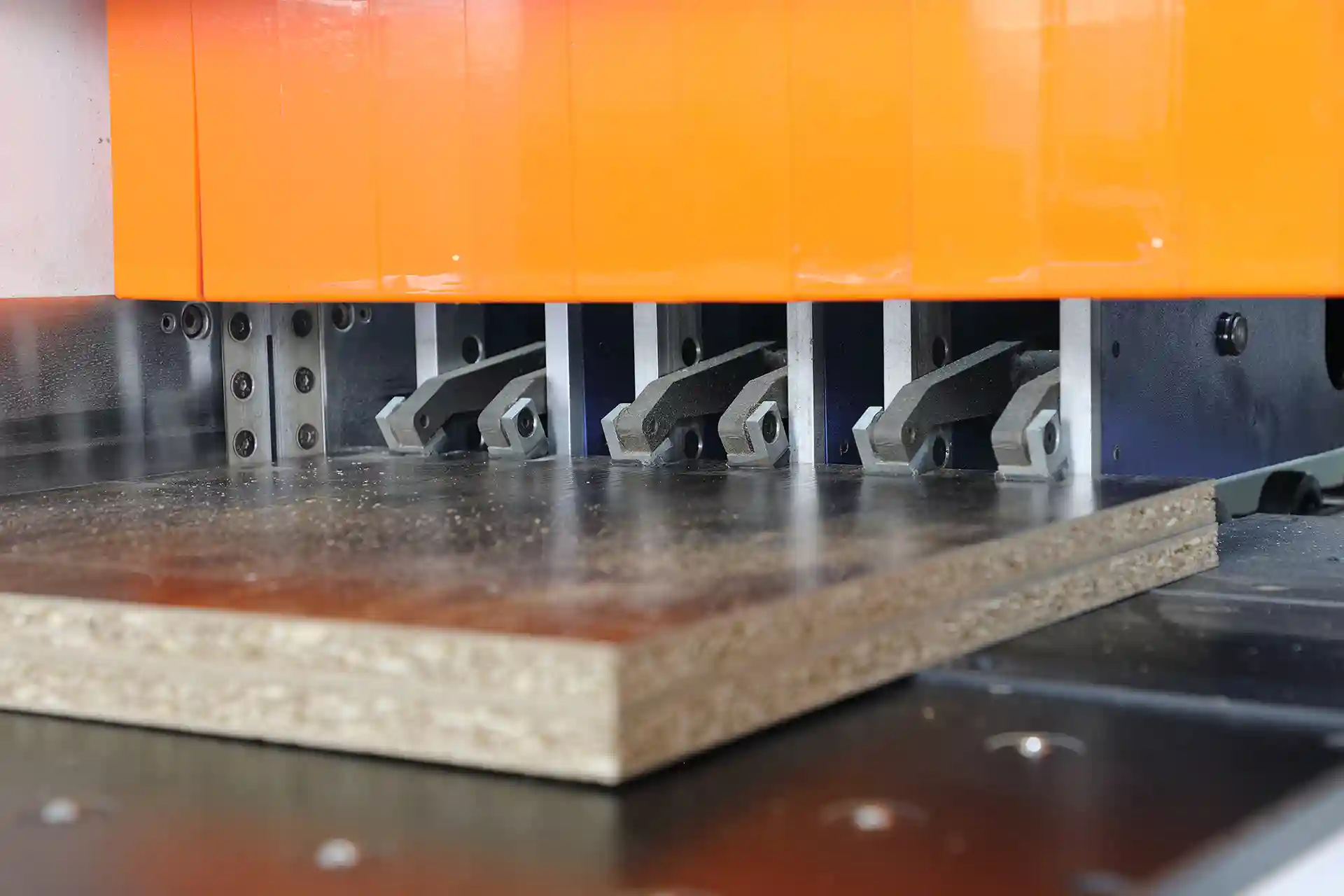

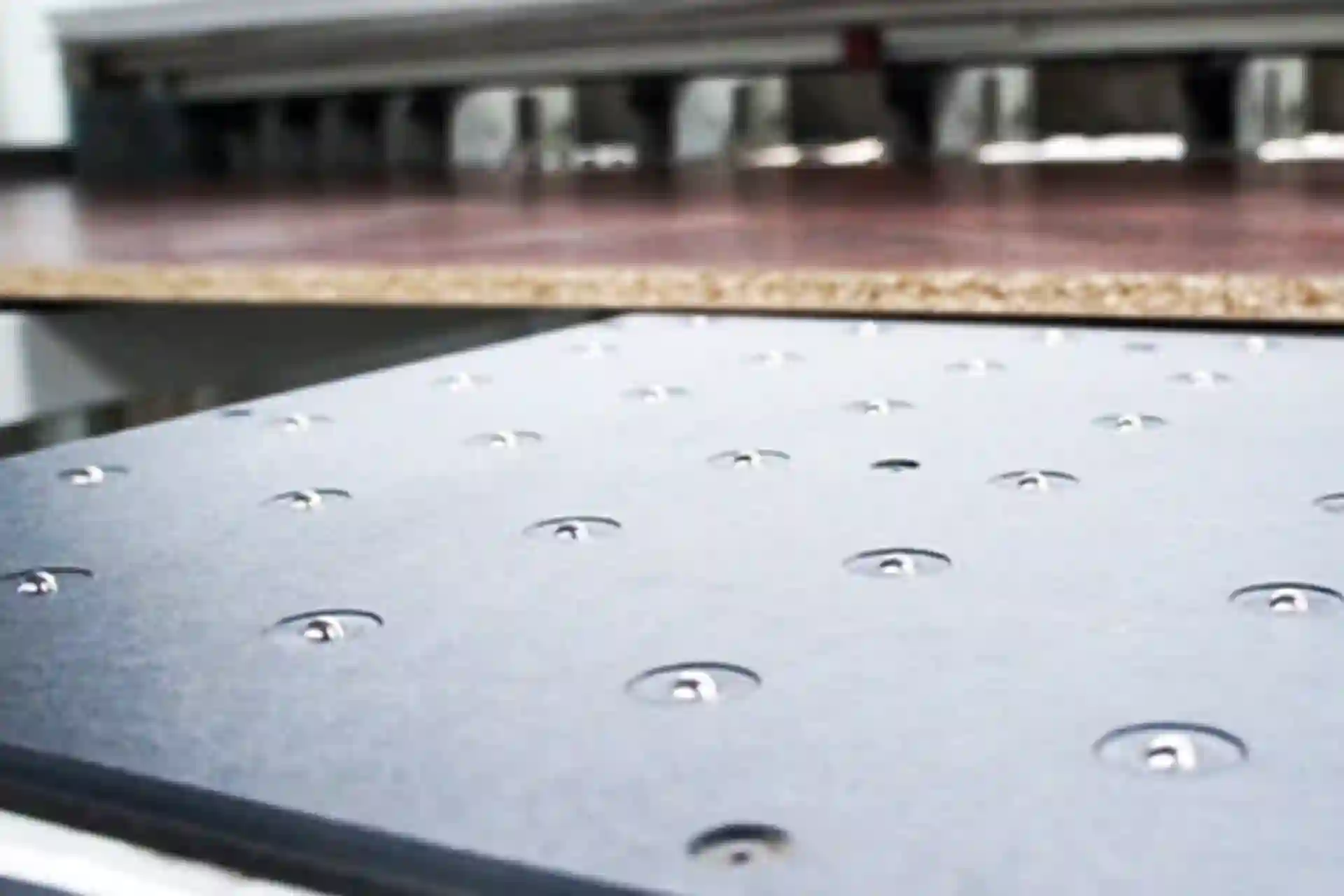

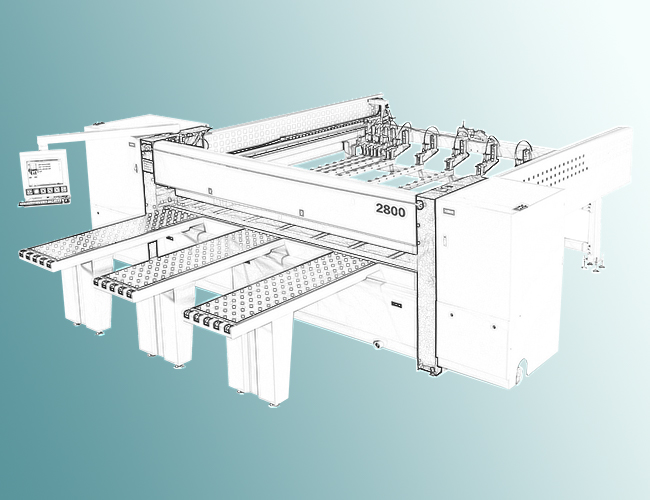

Front loading beam saws have revolutionized the way materials are processed in woodworking and manufacturing industries. These advanced machines allow for easy and efficient loading of large panels directly from the front, making the cutting process smoother and faster. By streamlining material handling, front loading beam saws improve workflow, reduce downtime, and increase overall productivity in manufacturing environments that require precise and high-volume cutting of wood-based panels and other large materials.

One of the key advantages of front loading beam saws is their ability to simplify material loading and unloading. Traditional saws often require more manual handling, which can slow down the production process and introduce potential errors. With a front loading system, operators can easily position large panels onto the machine, reducing the need for additional handling equipment and ensuring faster setup times. This improvement translates into a more efficient cutting process, allowing manufacturers to increase their output without sacrificing quality.

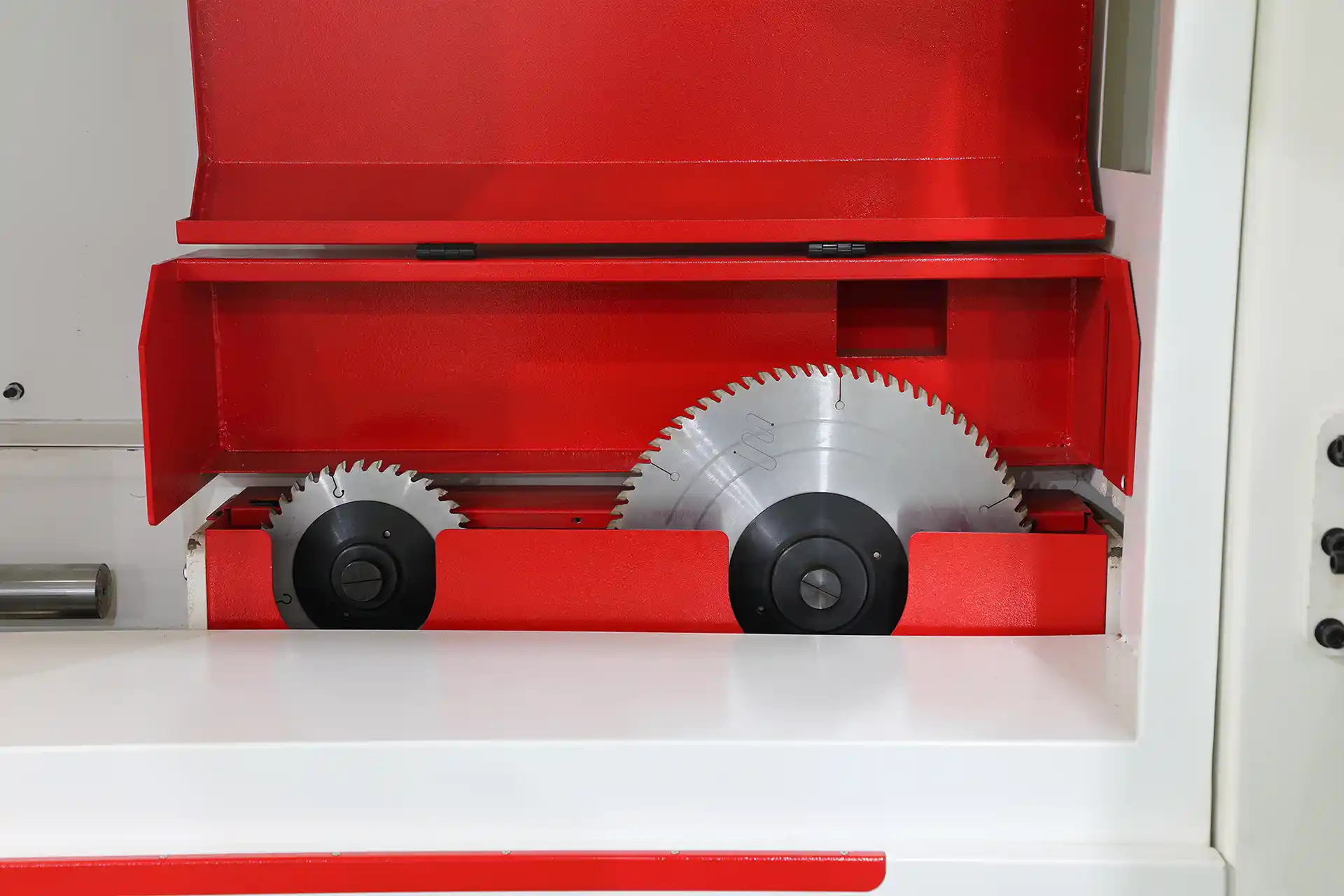

Front loading beam saws are equipped with advanced CNC (Computer Numerical Control) technology, ensuring high levels of precision and consistency in every cut. Whether cutting wood panels, laminates, or composite materials, these machines provide clean, accurate cuts with minimal waste. The integration of CNC technology allows operators to program complex cutting patterns and dimensions, ensuring that each panel is cut to exact specifications. This level of accuracy is critical in industries like furniture production, where even minor inconsistencies can impact the quality of the final product.

Front loading beam saws are particularly well-suited for high-volume production environments, where speed and precision are essential. Their ability to handle large panels quickly and efficiently makes them ideal for manufacturers who need to process significant amounts of material in a short time frame. The front loading feature reduces bottlenecks in the production line, ensuring a continuous flow of materials and maximizing productivity. This makes front loading beam saws a valuable asset for businesses looking to optimize their production capabilities.

Customized beam machines for cutting large panel sizes

All categories and models of panel saws that fit your production needs

The 2800 Woodsaw offers precise, high-performance wood cutting with customizable features.

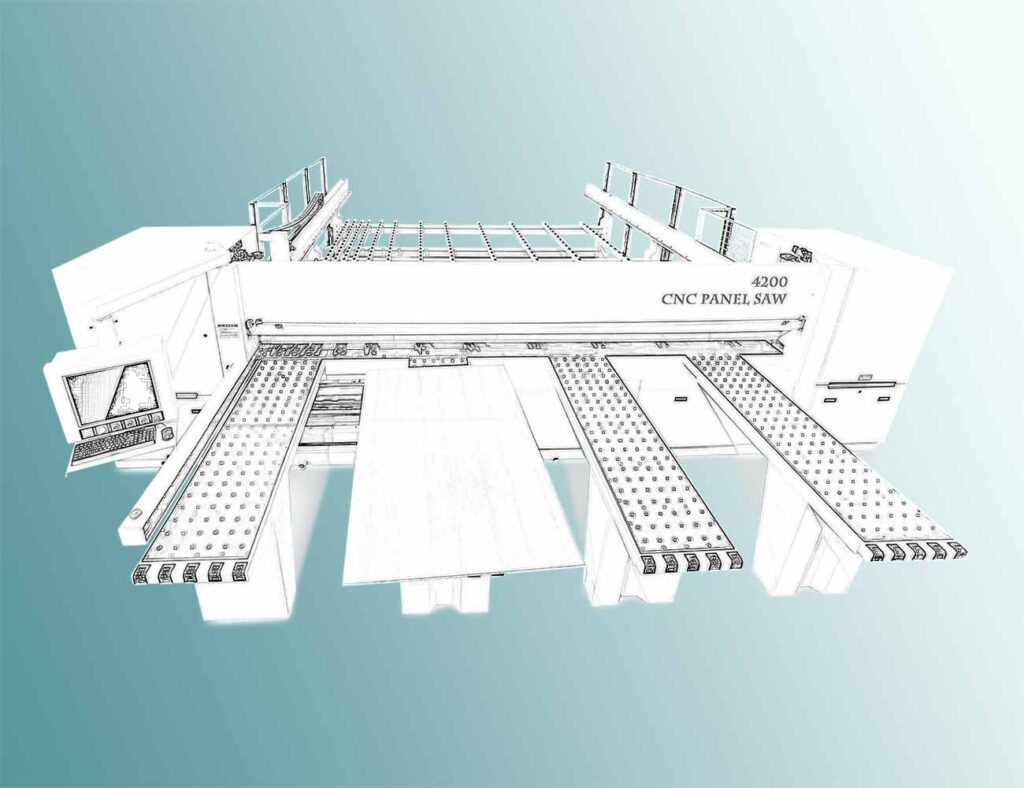

Origial manufactuer of 4200 CNC Wood Cutter, our 4200 Series of woodworking cutting machinery can elevate your furniture plant production cefficiency and capacity.

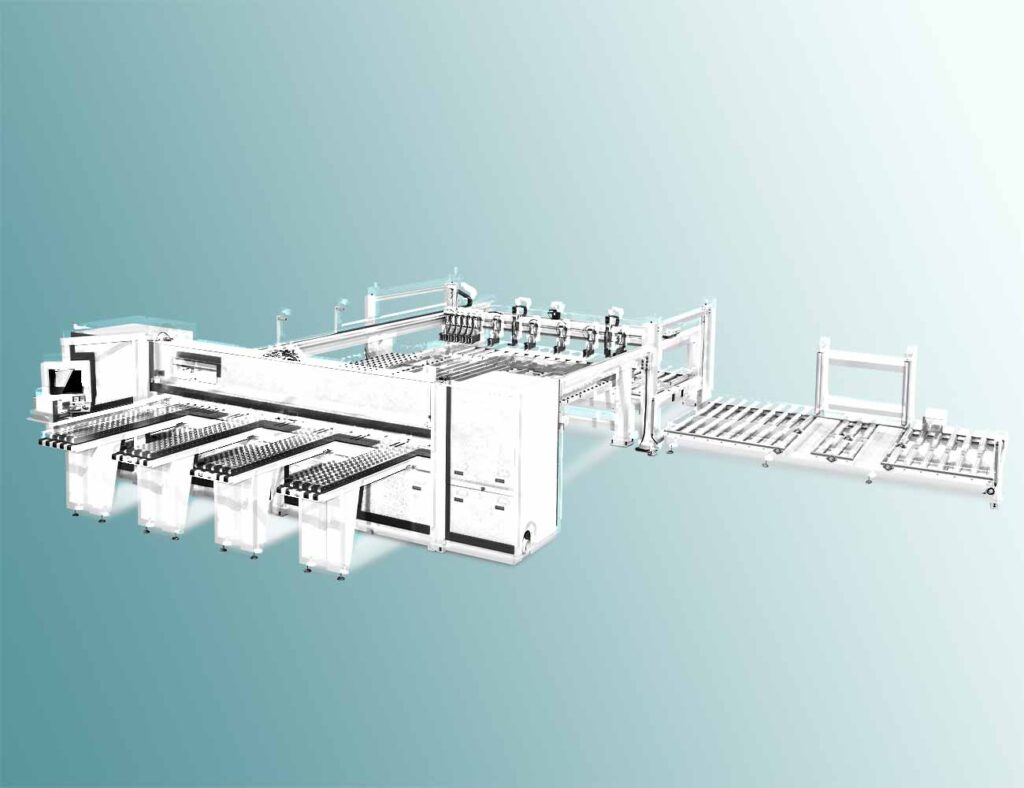

A fully customizable CNC panel saw offering precise, automated cutting for efficient, high-volume production for your plant

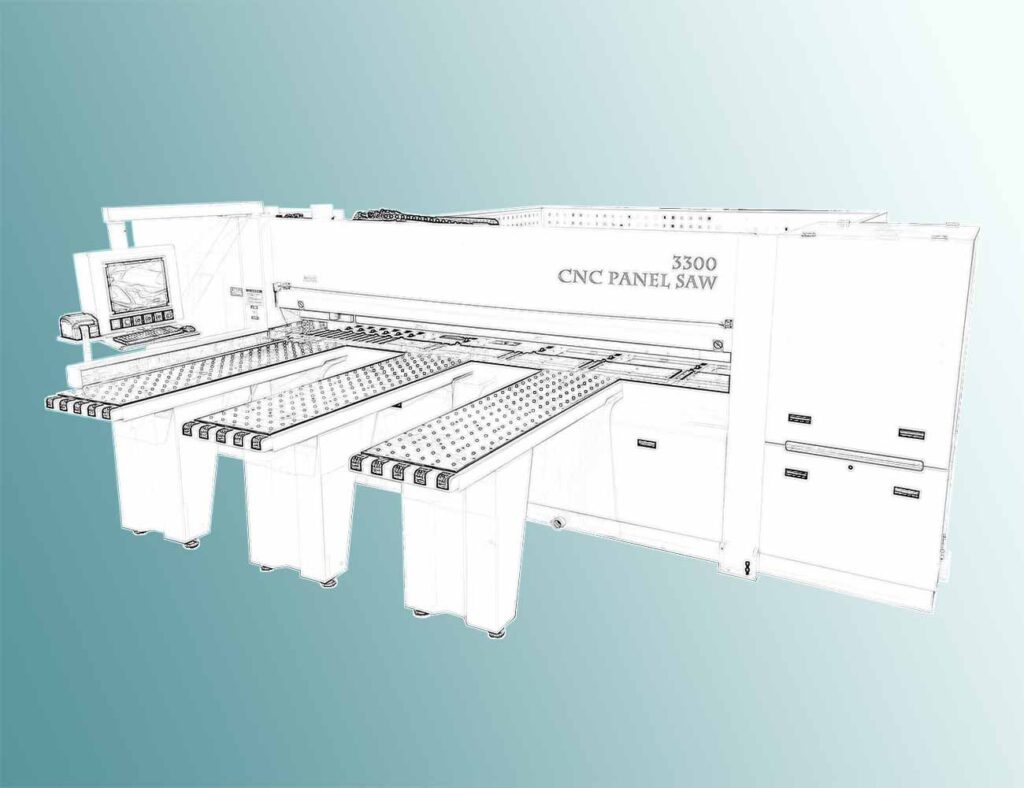

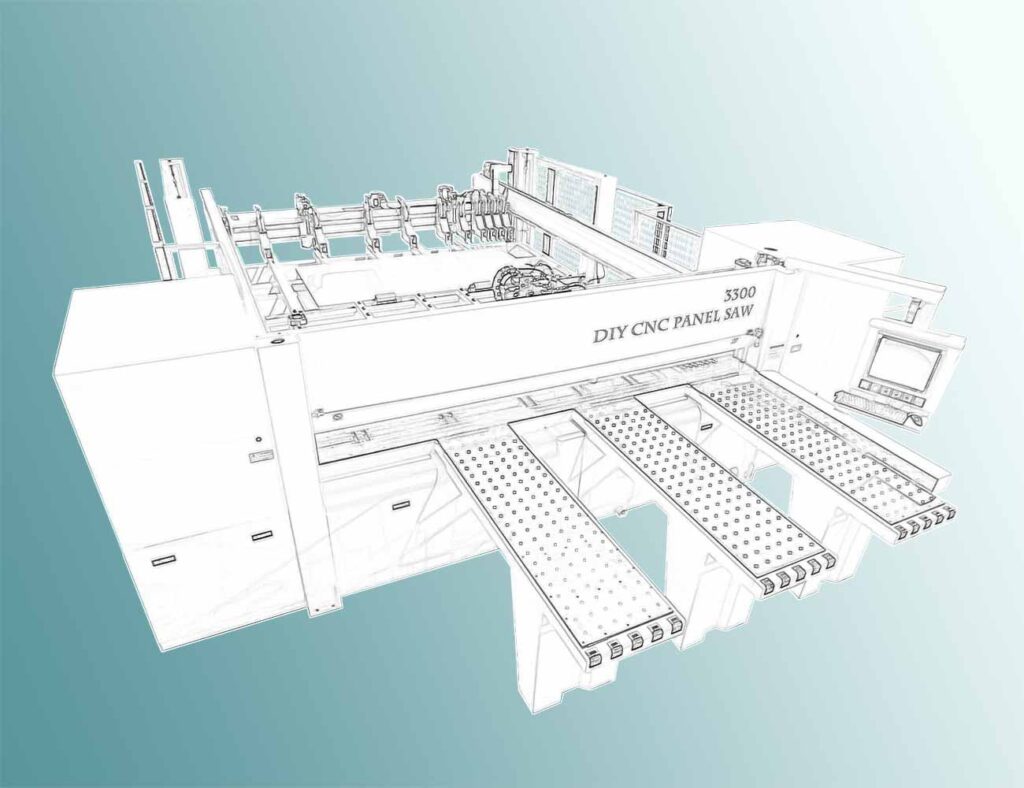

Enhance your woodworking precision with our high-performance 3300 Series of Saw Cutting Machine

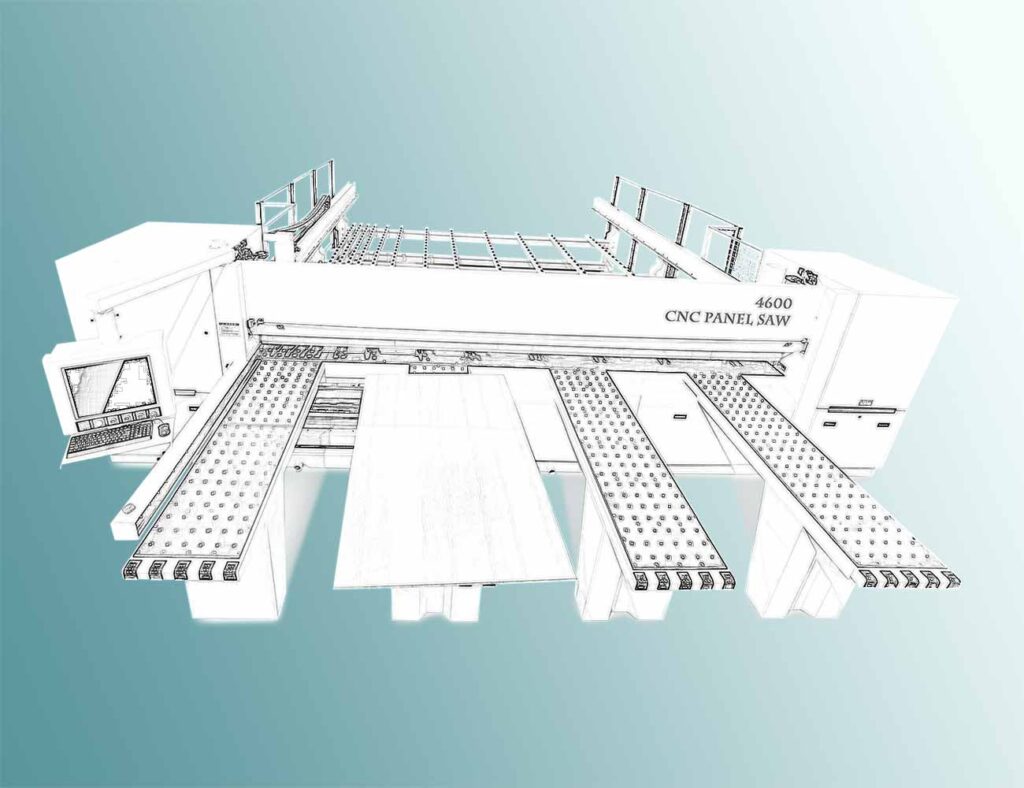

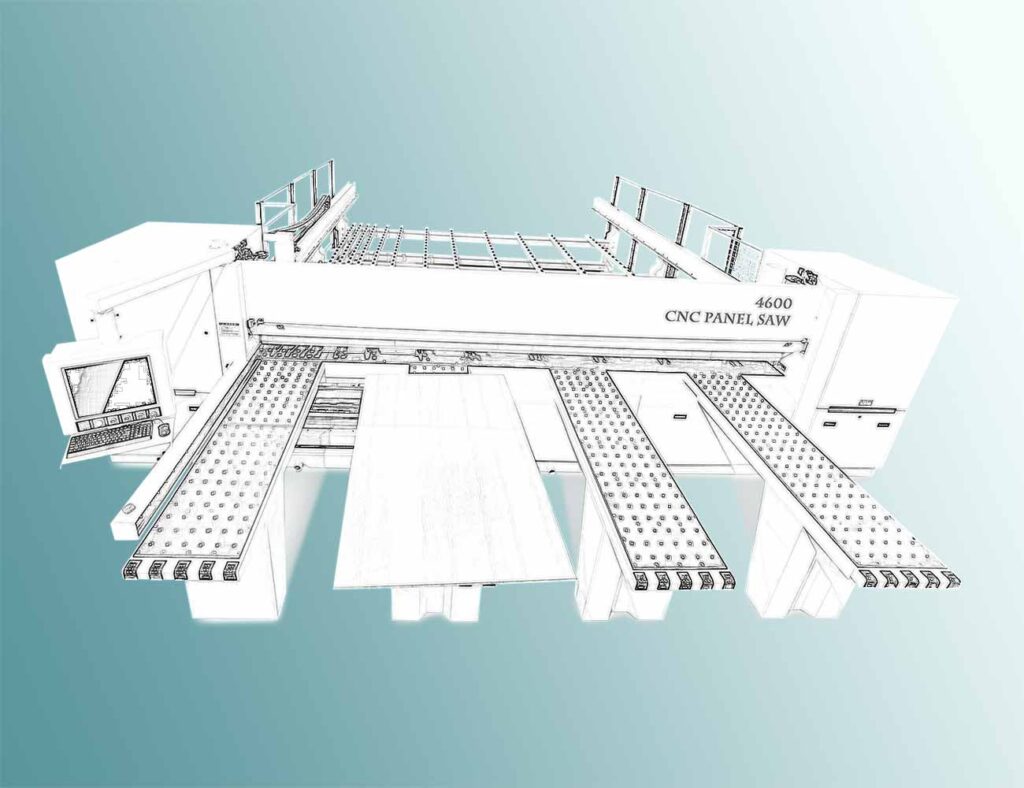

We are one of few manufacturers who provide 4600 Panel Saw Machine for your furniture produciton. Enable your furniture production for large-sized panels and furnitures.

Efficient beam saws designed for fast, precise cutting with easy front-loading capabilities. We provide all sizes from 2800 to 4600.

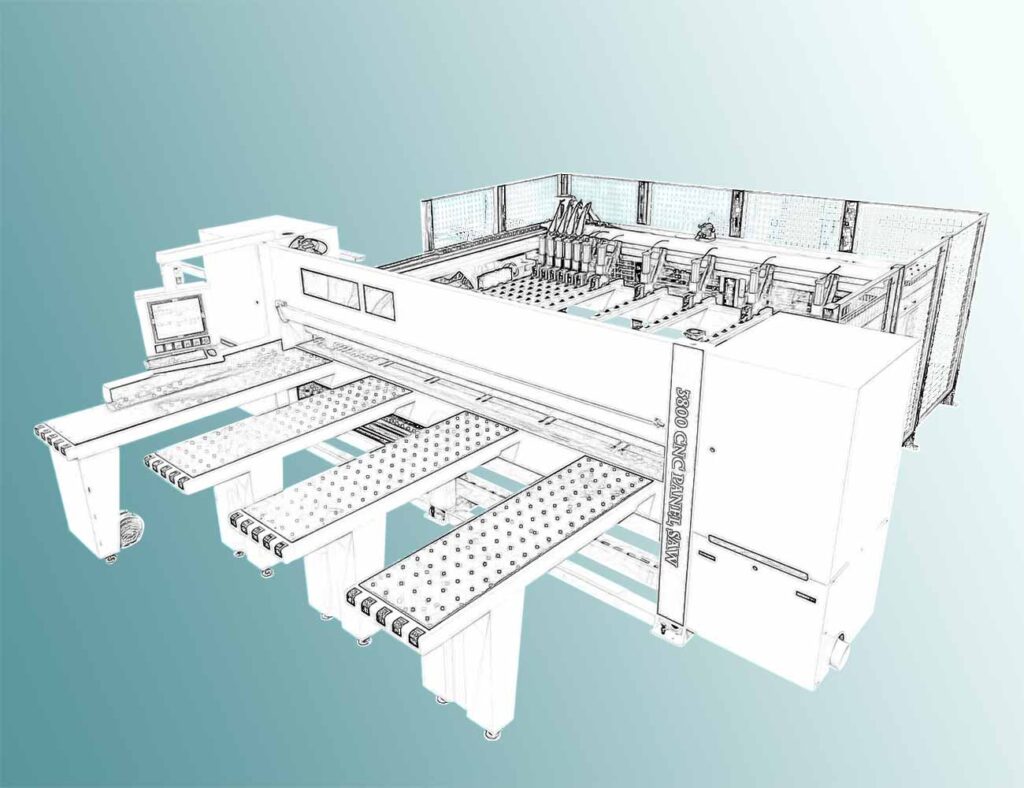

Experience superior woodworking capabilities with our advanced 3800 Wood Cutting Machines

If you are looking for DIY CNC Panel Saw factories, we are original manufacturer with technical capability, we can design and manufacture customize beam saws .

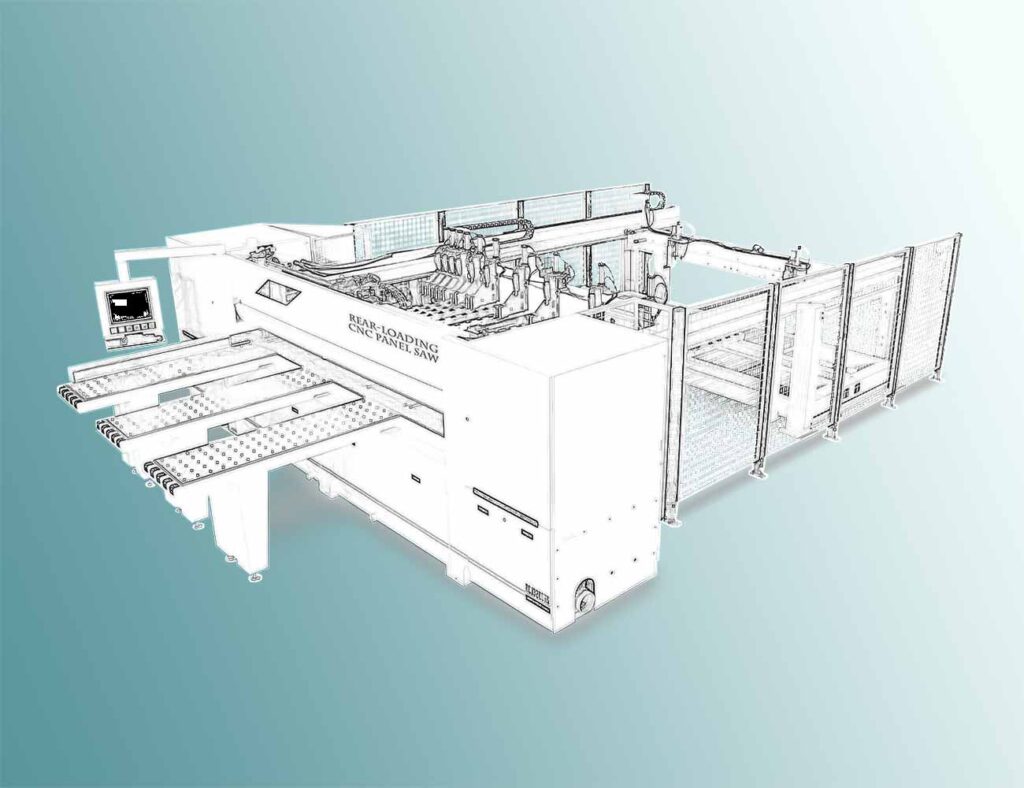

Efficient CNC saw with rear-loading design for streamlined, high-precision, automated cutting.

Capabiliteis and knowhow of smart factory design and solutions. A value-added service for our customers.