Professional Board Cutting Machines from original manufacturer for Fibreboard) Processing

Improve your woodworking projects with the power of professional board cutting machines

Fibreboard, a ubiquitous material in woodworking and construction, comes in various densities and thicknesses. While traditional saws might handle some Fibreboard varieties, tackling thicker or denser boards often requires a more robust solution. Here’s where a heavy-duty board cutting machine comes in, offering the power and precision needed for efficient and reliable Fibreboard processing.

What is Wood Fibreboard?

Wood Fibreboard is an engineered wood product composed of wood fibers compressed and bonded with resin or glue. Available in various densities, thicknesses, and grades, it offers a versatile and cost-effective alternative to solid wood for a wide range of applications.

Features of Fibreboard:

- Versatility: Fibreboard comes in various densities, including MDF (Medium-Density Fibreboard, HDF (High-Density Fibreboard), and LDF (Low-Density Fibreboard). This variety caters to different project needs, from furniture construction (MDF) to cabinet doors (HDF) and shelving (LDF).

- Machinability: Fibreboard’s uniform density allows for clean and precise cutting, shaping, and drilling with woodworking tools. This characteristic makes it a popular choice for creating intricate design elements and custom furniture pieces.

- Stability: Compared to solid wood, Fibreboard exhibits minimal shrinkage and warping, making it ideal for applications requiring dimensional stability, such as cabinet carcasses and interior doors.

- Cost-Effectiveness: Fibreboard offers a cost-effective alternative to solid wood for various applications. This affordability makes it a popular choice for budget-conscious projects while still delivering a smooth, high-quality finish.

Power Up Your Projects: Heavy-Duty Board Cutting Machines for Effortless Fiberboard Processing

Benefits of wood fiberboard:

- Versatility: Fiberboard comes in various densities, including MDF (Medium-Density Fiberboard), HDF (High-Density Fiberboard), and LDF (Low-Density Fiberboard). This variety caters to different project needs, from furniture construction (MDF) to cabinet doors (HDF) and shelving (LDF).

- Machinability: Fiberboard’s uniform density allows for clean and precise cutting, shaping, and drilling with woodworking tools. This characteristic makes it a popular choice for creating intricate design elements and custom furniture pieces.

- Stability: Compared to solid wood, fiberboard exhibits minimal shrinkage and warping, making it ideal for applications requiring dimensional stability, such as cabinet carcasses and interior doors.

- Cost-Effectiveness: Fiberboard offers a cost-effective alternative to solid wood for various applications. This affordability makes it a popular choice for budget-conscious projects while still delivering a smooth, high-quality finish.

- Smooth Surface: Fiberboard has a smooth and uniform surface, ideal for painting, laminating, or veneering to achieve a variety of finishes. This allows for greater design flexibility and customization in your projects.

- Lightweight: Compared to solid wood, fiberboard is lighter in weight. This can be an advantage for certain applications, such as furniture construction or wall panels, where weight reduction is desirable.

- Environmentally Friendly (with considerations): Fiberboard can be a more environmentally friendly option than solid wood, especially if made from recycled wood fibers. However, the environmental impact depends on the specific manufacturing process and resin used. Look for fiberboard made with recycled content and low-emission adhesives for the most sustainable option.

Overall, wood fiberboard offers a versatile, cost-effective, and stable material for a wide range of woodworking and construction applications.

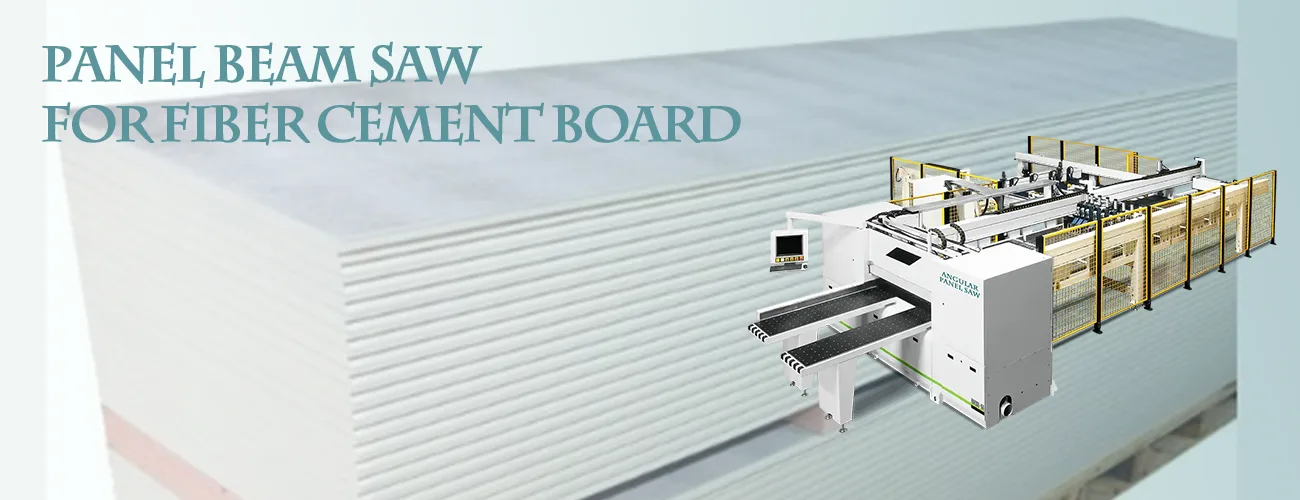

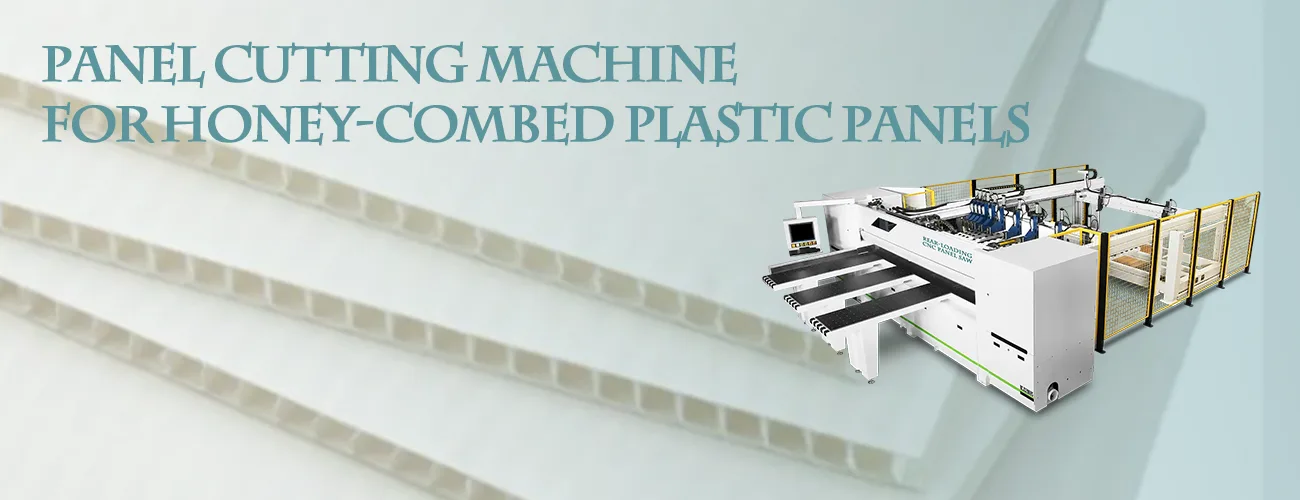

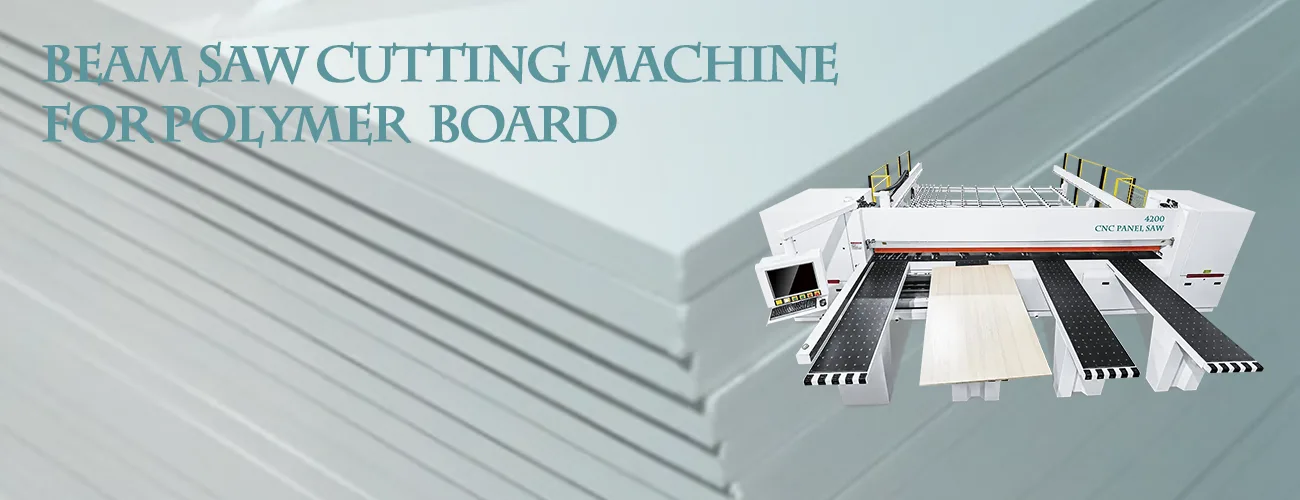

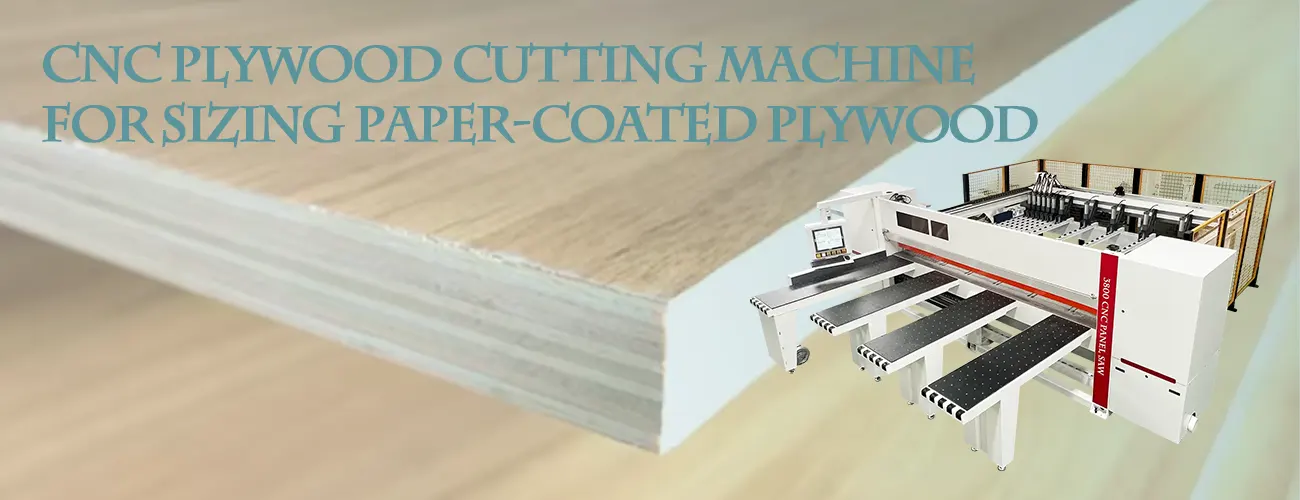

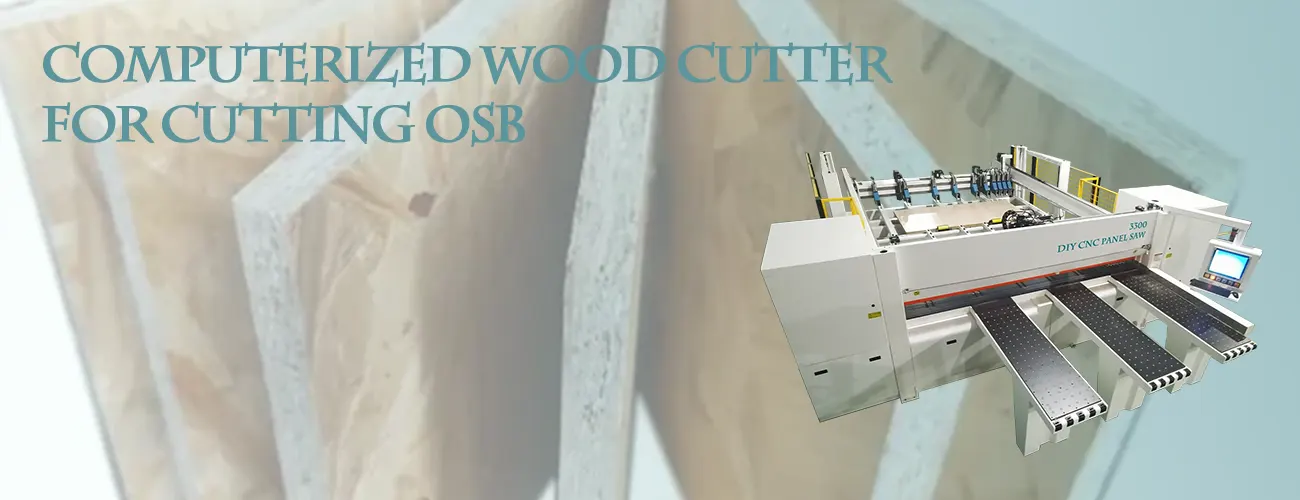

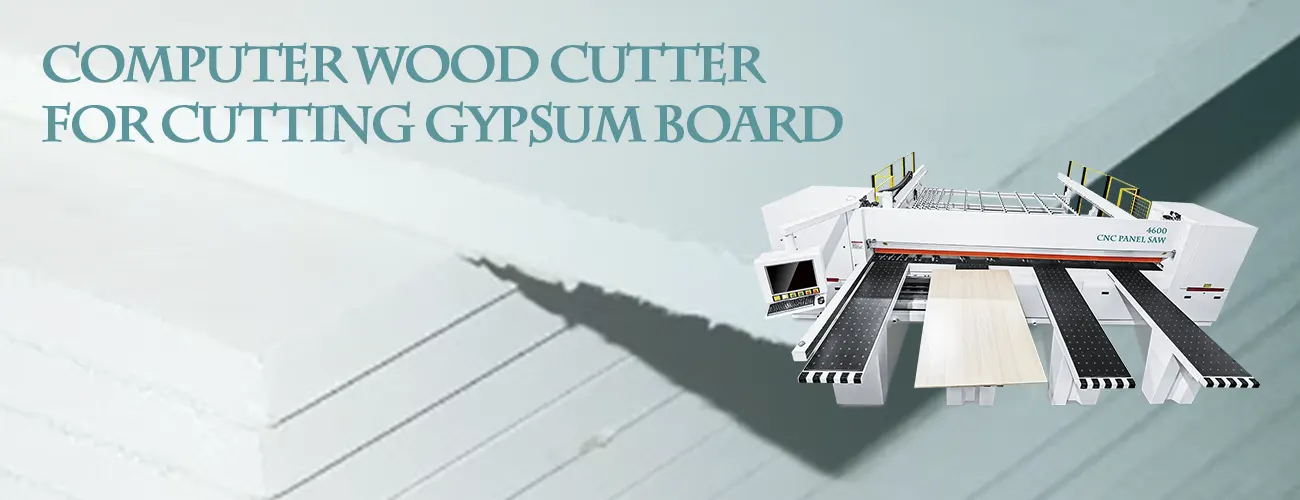

How Heavy-Duty Board Cutting Machines are Utilized in Fibreboard Processing

Heavy-duty board cutting machines are specifically designed to tackle the challenges of processing thicker and denser Fibreboards. Here’s how this advanced saw technology empowers efficient Fibreboard cutting:

- Industrial-Grade Power: Equipped with powerful motors and robust cutting blades, these machines effortlessly cut through even the densest Fibreboards, ensuring clean and precise results in a single pass. This eliminates the need for multiple passes or struggling with underpowered saws, saving time and effort.

- Precision Cutting Systems: Advanced cutting systems with features like laser guides and adjustable feed rates ensure accurate cuts. This precision minimizes chipping and delamination, crucial for preserving the integrity of the Fibreboard for structural applications or high-quality finishes.

- High Cutting Capacity: Heavy-duty board cutting machines boast impressive cutting capacities, allowing them to handle large and thick Fibreboard sheets. This translates to greater versatility in your projects, accommodating a wider range of Fibreboard sizes and eliminating the need for pre-cutting thicker sheets with less powerful saws.

- Automation Capabilities (Optional): Some advanced machines offer optional automation features, such as automatic feed systems and CNC (Computer Numerical Control) programming. These features streamline repetitive cutting processes, boosting productivity and minimizing human error for complex cuts.

Advantages of Our Heavy-Duty Board Cutting Machines for Fibreboard Sizing

Investing in a heavy-duty board cutting machine from our company offers several advantages for efficient and reliable Fibreboard processing:

- Effortless Cutting Performance: Our industrial-grade machines handle even the toughest Fibreboard materials with ease, ensuring clean and precise cuts every time. This translates to less rework, reduced waste, and a professional-looking finished product.

- Enhanced Workflow Efficiency: The power and high cutting capacity of our machines significantly reduce cutting times compared to traditional saws. This translates to increased productivity, allowing you to complete projects faster and meet deadlines more effectively.

- Reduced Material Waste: Precision cutting systems minimize waste and allow for optimized cutting layouts, getting the most out of your Fibreboard sheets. This saves you money on materials and promotes sustainable resource utilization practices.

- Versatility for Diverse Projects: Our high cutting capacity allows you to handle a wide range of Fibreboard sizes and thicknesses, making these machines suitable for various woodworking and construction projects.

- Advanced Safety Features: Our saws prioritize safety with features like blade guards, dust extraction systems, and emergency shut-off switches. These features create a safe working environment for your operators, minimizing the risk of accidents and injuries.

Invest in Power and Precision for Your Fibreboard Projects

Upgrade your Fibreboard processing capabilities with a heavy-duty board cutting machine from our company. Our machines empower you to achieve superior cutting performance, optimize your workflow, and elevate the quality of your Fibreboard projects. Contact us today to learn more about how our advanced saw technology can revolutionize your approach to Fibreboard cutting and unlock the full potential of this versatile and cost-effective material!