Achieve Precision Cuts: Woodcutting Machines Optimized for Glulam Beam Processing

Improve your woodworking projects with the power of CNC technology.

Glulam (Glued Laminated Timber) is a high-strength, engineered wood product experiencing a surge in popularity within the construction industry. While traditional woodcutting machines might seem like a viable option, they often lack the power, precision, and durability needed to effectively handle the robust nature of glulam beams. Here’s where a dedicated glulam beam saw comes in, offering a superior solution for glulam cutting. These specialized machines ensure clean, accurate cuts for optimal structural performance, contributing to the strength, stability, and overall quality of your construction projects.

What is Glulam?

Glulam is an engineered wood product composed of multiple layers of solid wood boards bonded together with structural adhesive. This unique layering process creates a remarkably strong and dimensionally stable material that offers distinct advantages over traditional solid wood beams:

- Superior Strength: The layered structure and high-quality adhesives used in glulam construction provide exceptional strength and load-bearing capacity. This makes glulam ideal for beams, headers, and other structural applications where superior strength is paramount. Compared to solid wood beams, glulam offers a more predictable and consistent level of strength, allowing engineers to optimize designs for maximum efficiency.

- Dimensional Stability: Glulam exhibits minimal shrinkage and warping compared to solid wood. This exceptional dimensional stability makes it ideal for applications requiring precise dimensions, such as columns and long-span beams. Reduced movement and warping in glulam beams translates to a more reliable and predictable performance in the final structure.

- Versatility: Available in various lengths, depths, and grades, glulam can be used for a wide range of structural applications. From beams and columns to arches and trusses, glulam’s versatility empowers architects and engineers to explore creative design possibilities while maintaining structural integrity.

- Aesthetic Appeal: Glulam offers a natural wood aesthetic that can be left exposed or stained to complement various architectural styles. The exposed wood grain adds warmth and character to interior spaces, while stained finishes can be used to achieve a specific design aesthetic.

Beyond Strength: Unveiling the Additional Benefits of Glulam

The benefits of glulam extend far beyond its core functionalities of strength and stability. Here are some additional advantages that make glulam a compelling choice for modern construction projects:

- Engineered Strength: Glulam beams are specifically designed to meet demanding structural requirements, offering a superior strength-to-weight ratio compared to solid wood. This allows for lighter yet stronger beam structures, contributing to overall building efficiency.

- Customizable Sizes: Glulam can be manufactured in various lengths and cross-sections to meet specific project requirements. This level of customization provides design flexibility for architects and engineers, allowing them to optimize beam sizes for specific loads and spans.

- Sustainability: Glulam utilizes smaller wood pieces, promoting efficient wood resource utilization and environmental sustainability in construction projects. By utilizing smaller, more readily available wood sections, glulam production minimizes waste and promotes responsible forestry practices.

- Fire Resistance: Modern adhesives enhance the fire resistance of glulam compared to traditional solid wood, offering an additional safety benefit. This improved fire resistance can be crucial for meeting building codes and safety regulations in certain construction projects.

How Woodcutting Machines Designed for Glulam Beams are Utilized

Glulam beam saws are specialized woodcutting machines specifically designed to handle the unique properties of glulam:

- Industrial-grade Power: These saws are equipped with powerful motors and robust cutting blades designed to efficiently cut through the layered structure of glulam beams. The increased power ensures clean cuts in a single pass, minimizing recuts and optimizing cutting efficiency.

- High-Precision Cutting Systems: Advanced cutting systems ensure accurate and clean cuts, minimizing chipping and delamination of the glued layers. This precision cutting is crucial for maintaining the structural integrity of the glulam beam, as any damage to the glued layers can compromise the overall strength of the beam.

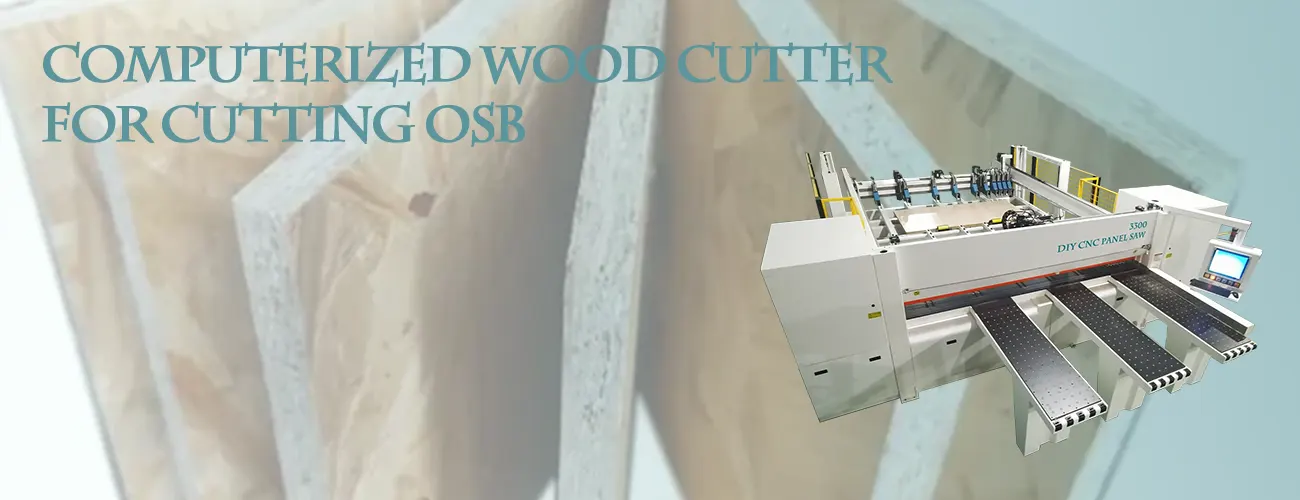

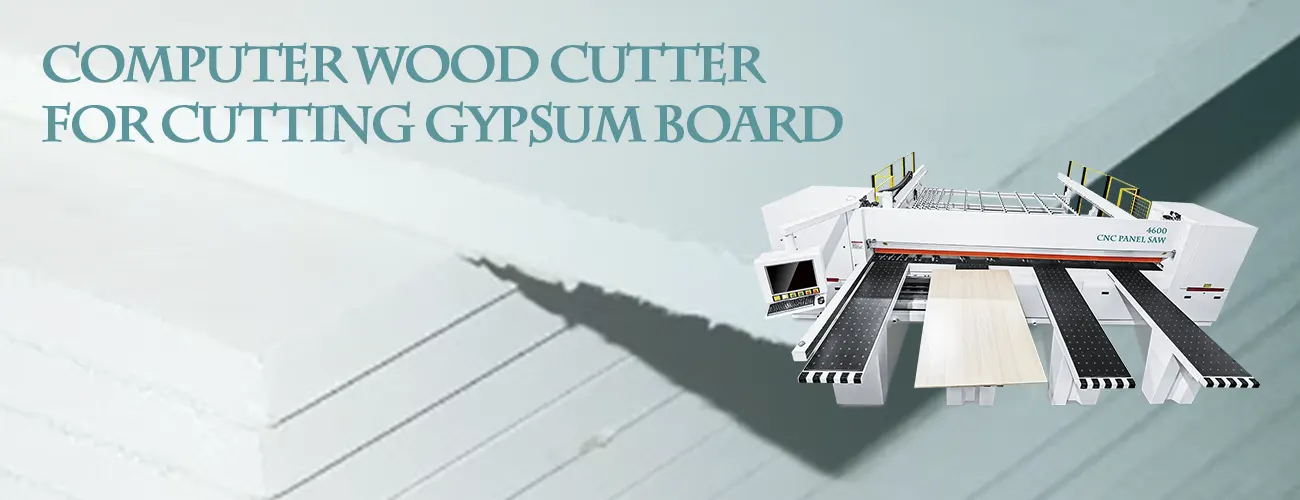

- Computerized Control Systems (Optional): Some glulam beam saws offer optional computerized control systems. These systems allow for precise programming of cutting parameters, such as blade depth and feed rate. Additionally, they can automate cutting processes for enhanced efficiency, particularly beneficial for repetitive cuts or complex beam geometries.

Advantages of Our Woodcutting Machines for Glulam Beam Sizing

Investing in a dedicated glulam beam saw from our company offers several advantages for efficient and precise glulam processing:

- Superior Cutting Performance: Our industrial-grade saws ensure clean and accurate cuts, minimizing waste and preserving the structural integrity of your glulam beams. This translates to a high-quality finished product that meets stringent construction standards. Clean cuts also minimize the need for additional finishing work, saving you time and resources.

- Enhanced Efficiency: The power and precision of our glulam beam saws significantly reduce cutting times compared to traditional woodworking machines. This translates to increased productivity and faster project completion times, allowing you to meet deadlines and keep your construction projects on track.

- Reduced Material Waste: Accurate cutting processes minimize scrap material, saving you money on glulam and promoting sustainable resource utilization practices. By optimizing cutting layouts and minimizing waste, you get the most out of your glulam materials, reducing costs and environmental impact.

- Versatility: Our glulam beam saws can handle a wide range of glulam beam sizes and thicknesses, making them suitable for diverse construction projects. Whether you’re working with standard-sized beams or require custom cuts for unique designs, our saws offer the power and adjustability to handle the job effectively.

- Safety Features: Our machines prioritize safety with features like blade guards, dust extraction systems, and emergency shut-off switches. These features create a safe working environment for your operators, minimizing the risk of accidents and injuries during the cutting process.

- User-Friendly Operation: Our glulam beam saws are designed with user-friendly controls and intuitive interfaces. This allows for easy operation, even for workers with limited experience operating specialized machinery. Reduced training time translates to faster deployment of the saws in your workshop, maximizing their impact on your workflow.

Invest in a Reliable Solution for Your Glulam Cutting Needs

As a leading supplier of woodworking machinery, we understand the importance of precision and efficiency in glulam beam processing. Our dedicated glulam beam saws empower you to achieve superior cutting performance, optimize your workflow, and elevate the quality of your construction projects. Contact us today to learn more about how our glulam beam saws can revolutionize your approach to glulam cutting and unlock the full potential of this versatile and high-performance building material! Whether you’re a large-scale construction company or a specialized woodworking workshop, our glulam beam saws offer a reliable and efficient solution for all your glulam cutting needs.