2800mm front feeding beam saw for sale

Standard 3300mm front-loading beam machine

Large size 3800mm front-loading beam saws for sale

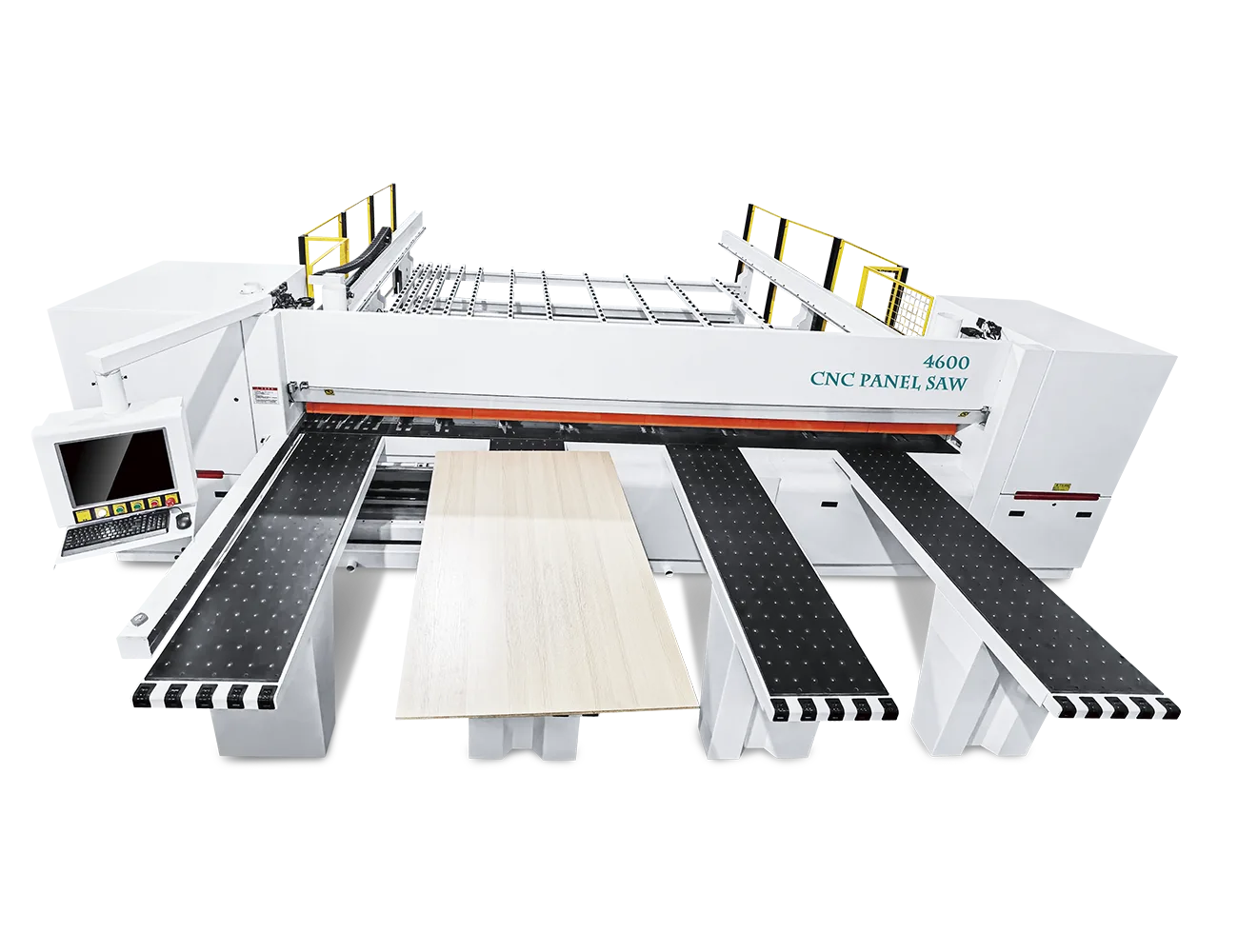

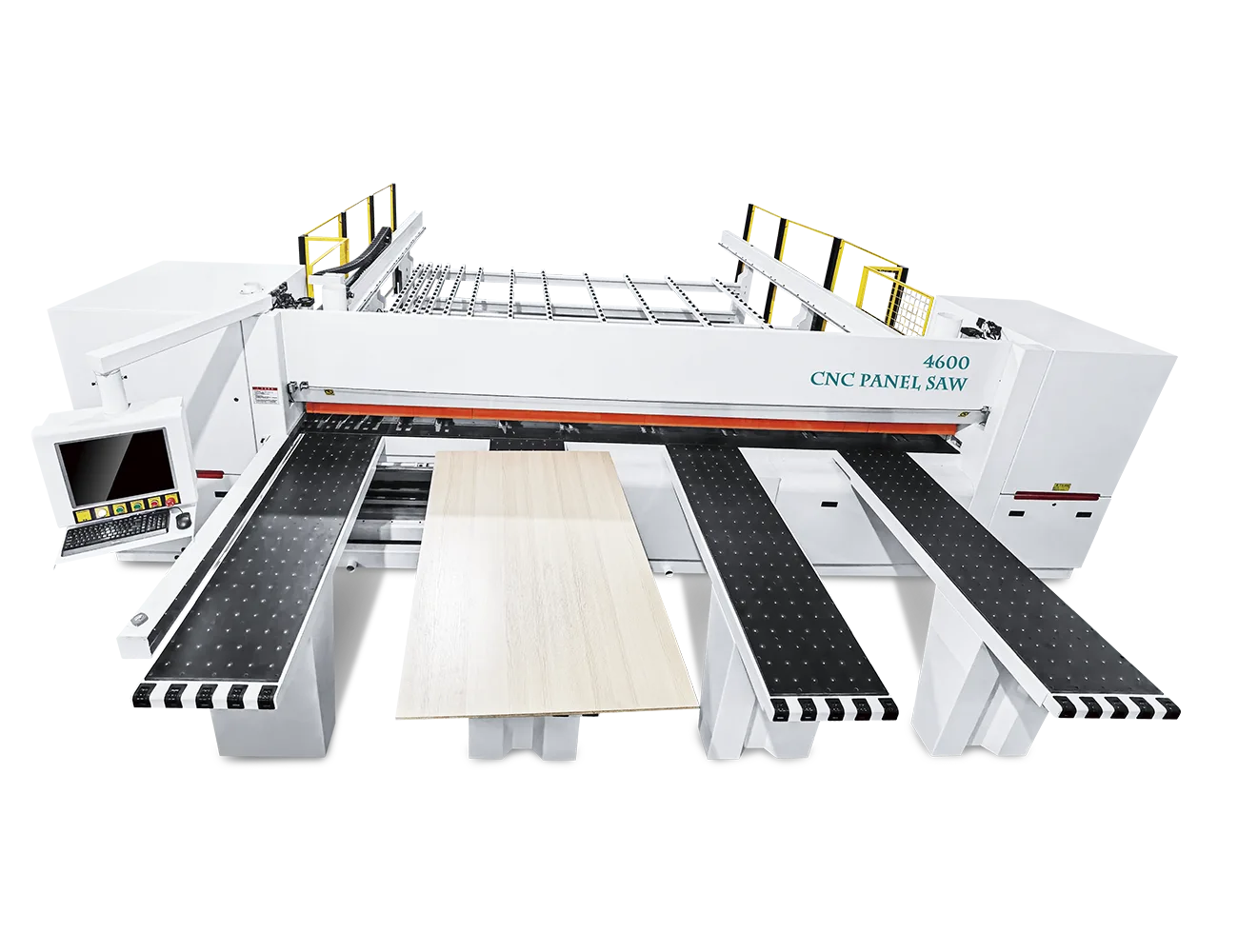

4200mm/4600mm computer beam saws with front-loading.

Looking for a powerful and reliable beam saw to elevate your woodworking operation? Look no further! Here at our factory, we’re a leading supplier of high-quality beam saws for sale, featuring a wide range of front-loading models to meet your specific production needs.

Front-loading beam saws offer efficient cutting solutions for various panel materials. Our models boast impressive cutting capacities, with options including:

2800mm front feeding beam saw for sale

Standard 3300mm front-loading beam machine

Large size 3800mm front-loading beam saws for sale

4200mm/4600mm computer beam saws with front-loading.

Our beam saws incorporate cutting-edge technology to deliver exceptional results. These advanced features include:

Built with cutting-edge technology, this machine is built to withstand demanding workloads and deliver long-term performance.

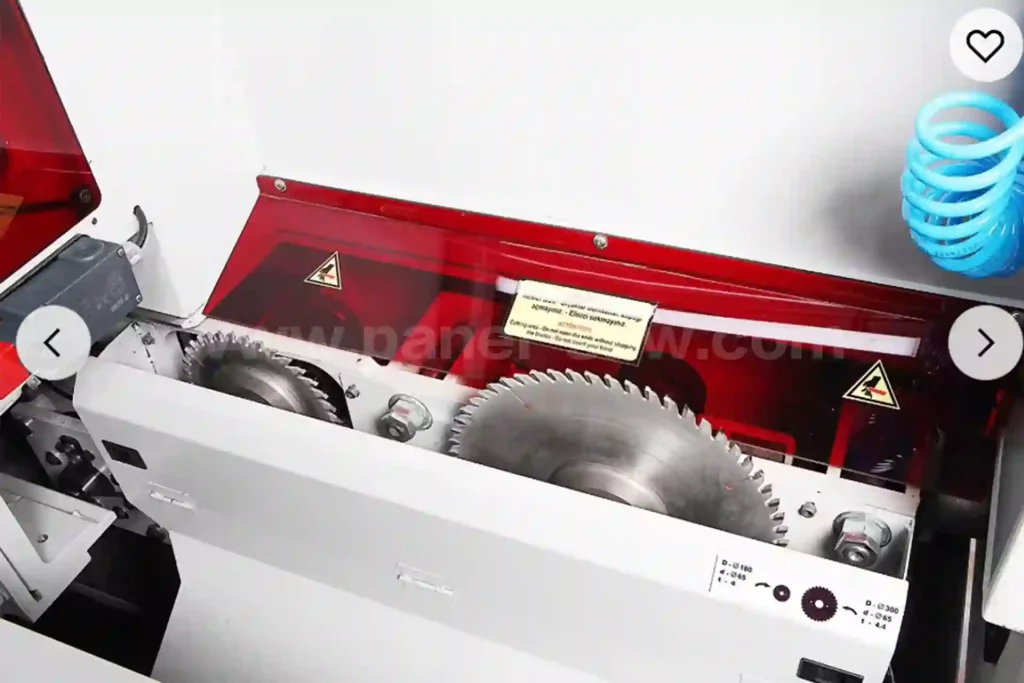

This high-quality saw shaft ensures clean and precise cuts.

This configuration offers optimal cutting performance for various material thicknesses.

This design enhances stability and cutting accuracy.

When it comes to panel cutting in woodworking, there are two primary solutions: CNC nesting machines and computer beam saws.

Our computer beam saws embody these advantages perfectly. With over 12 years of experience, we design and manufacture top-of-the-line panel saws trusted by woodworking businesses worldwide. Our computer beam saws are a popular choice for furniture production in countless woodworking plants and factories.

Our factory prioritizes quality and durability in every machine we produce. The 2800mm High-Speed Intelligent Computer Woodsaw is no exception. Here’s a detailed look at the meticulous production process that goes into crafting the machine saw framework, the heart of this powerful tool:

This meticulous approach is extended to all sheet metal parts, including the panel pressing beam and manipulator beams. These components are precisely shaped according to detailed engineering specifications. They then undergo surface treatment through phosphating, powder coating, or painting to enhance corrosion resistance and aesthetics.

In the final stages, all electrical components and accessories are meticulously prepared and integrated with the framework. Skilled technicians then perform the final assembly, ensuring all parts function flawlessly together. Finally, our software experts install and commission the operating system, guaranteeing the saw is ready to operate at peak performance upon arrival at your workshop.

As a professional manufacturer for the CNC wood cutting machine, we can provide the one-stop solution for our customer regarding their wood sizing needs.

To make our customer satisfied with us, we have prepared enough talents such as machine design technician with over 20 years experiences in woodworking industry, as well as assembly workers with over 10 years experiences, to produce high-quality Computer Beam Saws, we not only provide the standard machine like 2800/3300 CNC Panel Saw, 3800 CNC wood cutting machine, but also provide custom machines like 4600mm beam saws.

For the sake of our customers, we also have trained lots of experienced workers to assemble the machines, and finish the whole process of manufacturing qualified beam saws. Here is what we can offer as below: