Pioneering Precision: Original Factory Horizontal Beam Saws for Lightweight Furniture Production

Improve your woodworking projects with the power of Horizontal Beam Saws

Lightweight furniture panels, increasingly popular for their versatility and affordability, are revolutionizing furniture design and manufacturing. However, achieving clean and precise cuts in these panels requires specialized equipment. This is where horizontal beam saws, also known as wood beam saws or big saw machines, come into play. As the original factory of these saws, we offer unparalleled expertise and cutting-edge technology to ensure efficient and accurate processing of lightweight furniture panels, taking your furniture production to the next level.

What are Lightweight Furniture Panels?

Lightweight furniture panels encompass a variety of composite materials engineered for furniture construction. These panels offer a combination of affordability, workability, and aesthetics, making them ideal for a wide range of furniture applications. Here are some of the most common types:

- Particleboard: Composed of wood particles bonded with resin, particleboard offers a cost-effective option for furniture components. It’s suitable for applications where structural integrity is not the primary concern, such as cabinet backs or drawer bottoms.

- MDF (Medium-Density Fiberboard): Made from finely ground wood fibers compressed with resin, MDF offers a smooth, uniform surface ideal for painting or laminating. Its increased density compared to particleboard provides improved strength and screw-holding capabilities, making it suitable for a wider range of furniture applications.

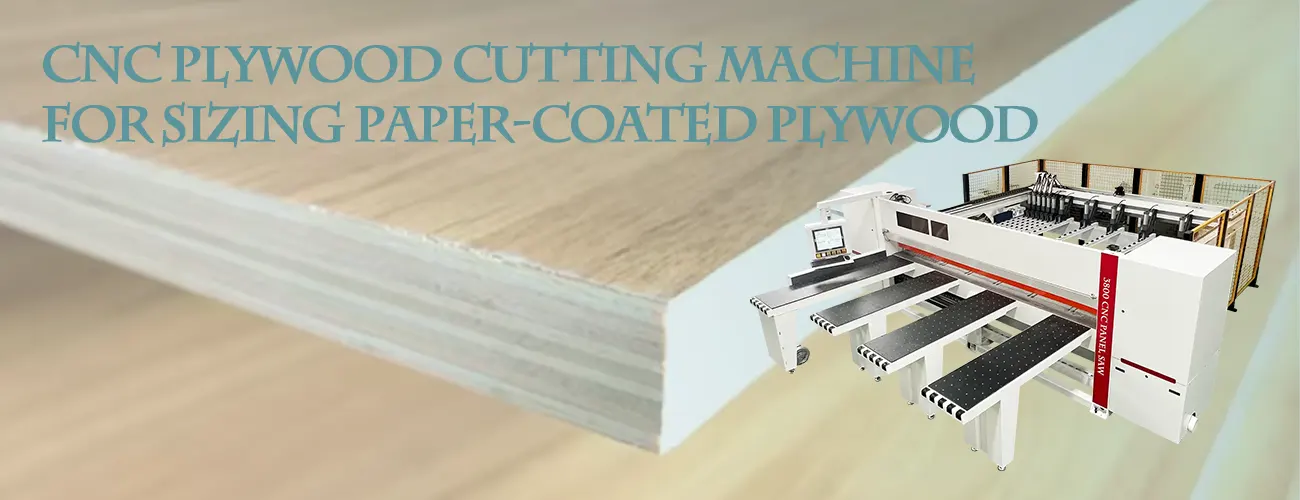

- Plywood: Composed of thin wood veneers bonded together with adhesive, plywood offers superior strength and dimensional stability compared to particleboard or MDF. Its layered construction makes it resistant to warping and provides good screw-holding capabilities.

Features of Lightweight Furniture Panels:

- Versatility: Lightweight furniture panels are available in various thicknesses, sizes, and finishes, catering to diverse furniture design needs. They can be veneered, laminated, or painted to achieve a variety of aesthetic finishes.

- Workability: These panels are relatively easy to cut, drill, and shape using woodworking tools. This makes them ideal for a variety of furniture production techniques, from traditional joinery to CNC machining.

- Affordability: Compared to solid wood, lightweight furniture panels offer a more cost-effective option for furniture construction. This allows manufacturers to create high-quality furniture at competitive prices.

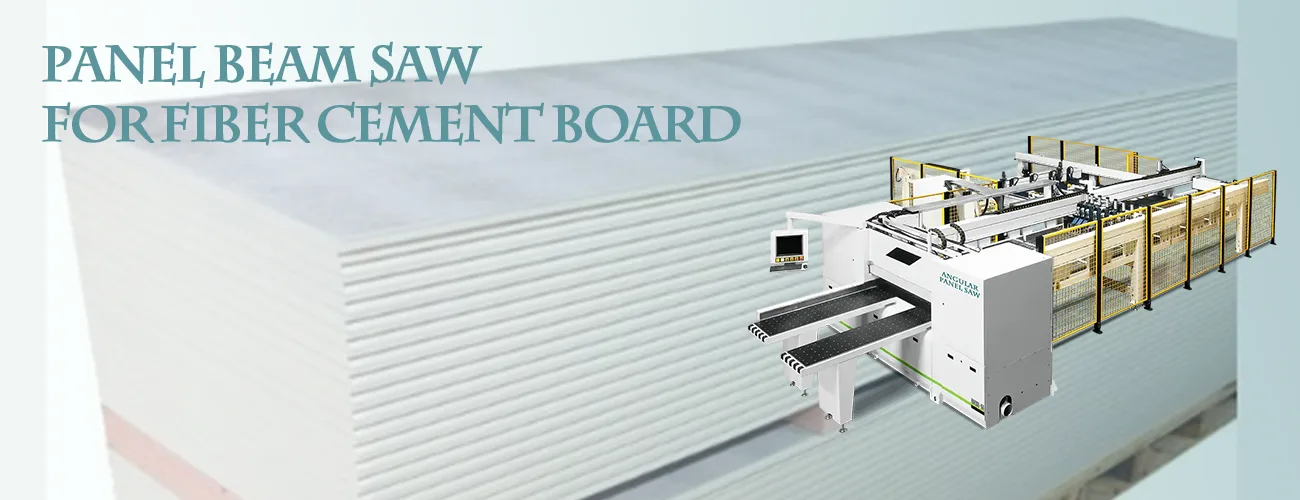

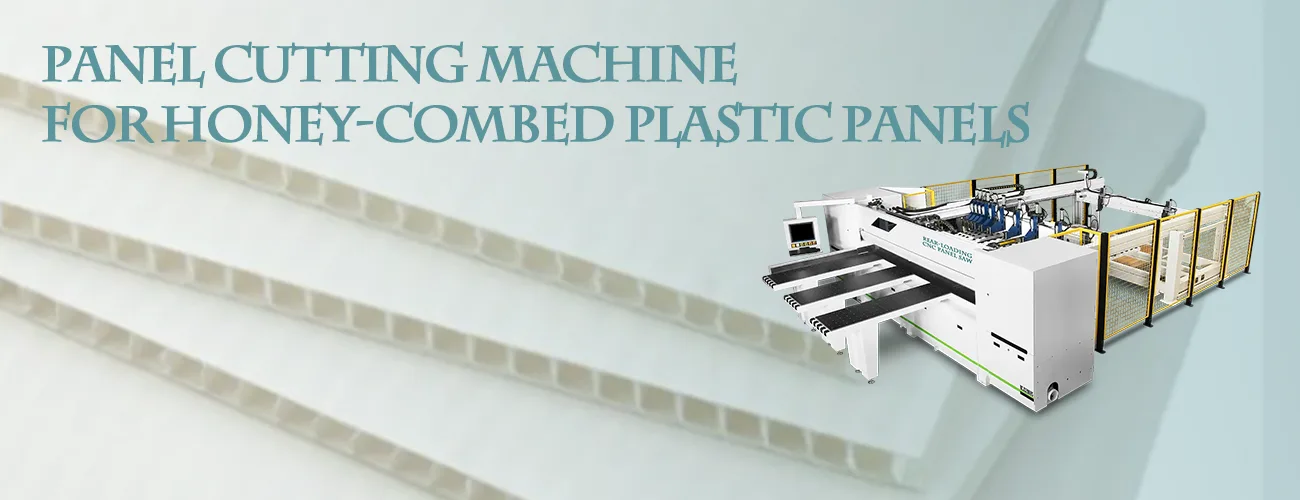

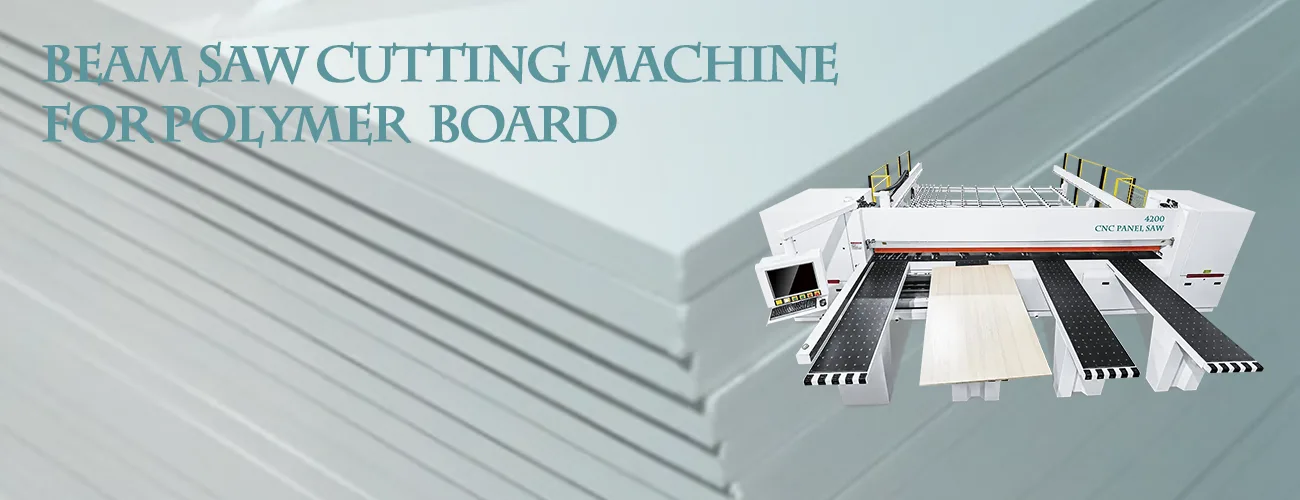

How Horizontal Beam Saws (Wood Beam Saws or Big Saw Machines) are Utilized in Cutting Lightweight Furniture Panels

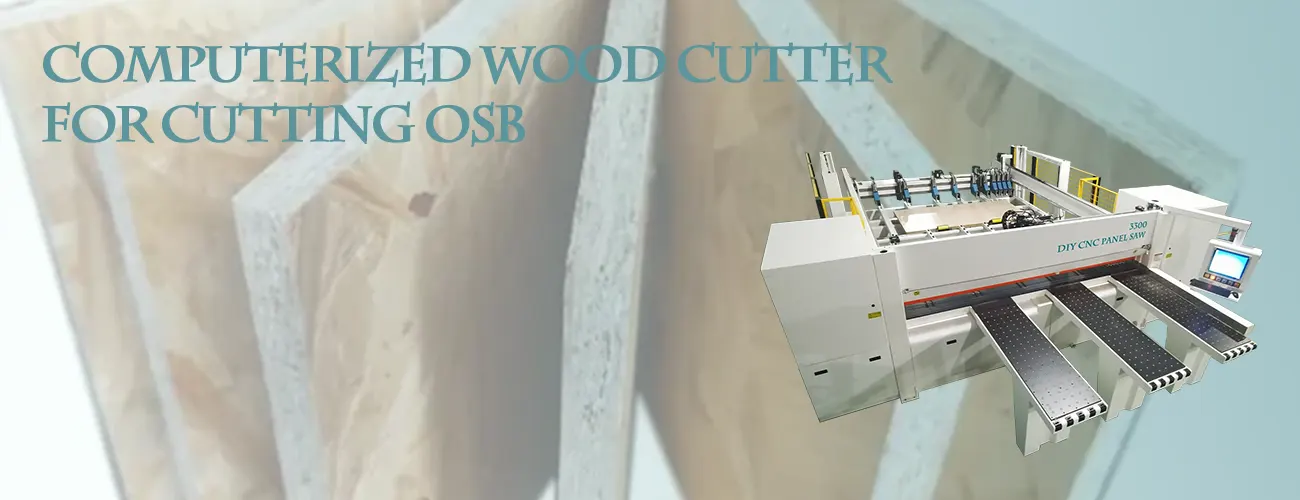

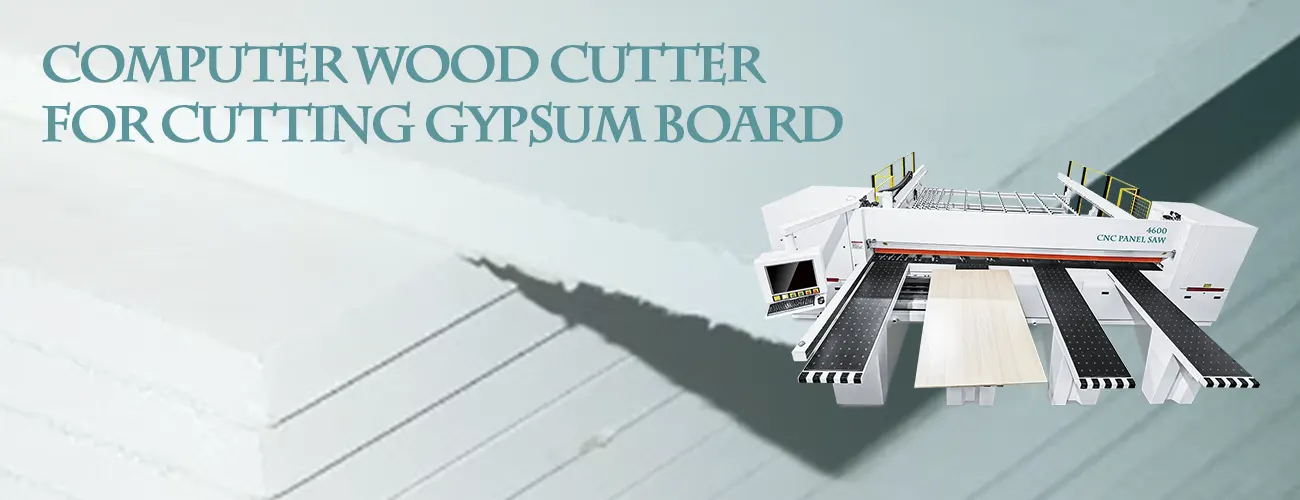

Horizontal beam saws, also known as wood beam saws or big saw machines, are specifically designed for efficient and precise cutting of panel materials, including lightweight furniture panels. Here’s how these advanced machines empower furniture production:

- Automated Cutting Processes: Horizontal beam saws are computer-controlled, allowing for precise programming of cutting parameters like length, width, and angle. This automation eliminates human error and ensures consistent, repeatable cuts for all furniture panel components.

- High-Precision Cutting Systems: These saws utilize high-quality blades and sophisticated cutting systems to achieve clean and chip-free cuts. This precision cutting minimizes damage to the panel surface, preserving the aesthetic appeal of the furniture and preventing premature wear.

- Dust Extraction Systems: Integrated dust extraction systems effectively capture dust particles generated during the cutting process. This promotes a clean working environment for operators, minimizes the risk of respiratory irritation, and allows for better visibility during cutting operations.

- Batch Cutting Capabilities: Horizontal beam saws excel at handling large quantities of lightweight furniture panels. Operators can program multiple cuts simultaneously, allowing for efficient batch processing of panels for large furniture production runs.

Advantages of Our Original Factory Horizontal Beam Saws (Wood Beam Saws) in Sizing Lightweight Furniture Panels

As the original factory of horizontal beam saws, we offer a legacy of expertise and innovation in panel cutting technology. Investing in one of our saws for your furniture production line provides several advantages:

- Superior Cutting Performance: Our industrial-grade saws ensure clean and accurate cuts, minimizing waste and preserving the integrity of your lightweight furniture panels. This translates to a professional-looking finished product with minimal rework required, saving you time and resources.

- Enhanced Production Efficiency: The automated cutting processes and batch processing capabilities of our horizontal beam saws significantly reduce cutting times compared to manual methods. This translates to faster furniture production cycles, improved throughput, and increased productivity for your operation.

- Reduced Material Waste: Precision cutting systems minimize scrap material, allowing you to optimize the use of your lightweight furniture panels. This not only reduces material costs but also aligns with responsible resource management practices.

- Versatility for Diverse Panel Types: Our horizontal beam saws can handle various lightweight furniture panel sizes, thicknesses, and materials, including particleboard, MDF, and plywood. This versatility makes them suitable for a wide range of furniture production needs.

- Proven Reliability – Built on Decades of Expertise: As the original factory of horizontal beam saws, we have a long history of innovation and refinement in this technology. Our saws are renowned for their durability, reliability, and minimal maintenance requirements. This translates to long-lasting performance and minimal downtime for your furniture production line.

Beyond Efficiency: the Creative Potential of Horizontal Beam Saws

While efficiency remains a critical aspect, horizontal beam saws (wood beam saws or big saw machines) offer more than just fast and precise cutting for furniture makers. These machines unlock a world of creative possibilities:

- Complex Furniture Designs: The precise control and repeatability of horizontal beam saws allow for the creation of intricate cuts and angles on lightweight furniture panels. This opens doors for designing and producing furniture with unique shapes, geometric patterns, or integrated features.

- Nesting Software Optimization: Advanced horizontal beam saws often integrate with nesting software. This software optimizes the layout of multiple cuts on a single panel, minimizing material waste and maximizing the utilization of lightweight furniture panels for efficient material usage.

- Precise Grooves and Dados: The high precision of these saws allows for the creation of clean and accurate grooves and dados in lightweight furniture panels. This is crucial for strong and aesthetically pleasing joinery techniques used in furniture construction.

- Integration with CNC Machining: Horizontal beam saws can be integrated into a production line alongside CNC machining centers. This combination allows for efficient cutting of large panels followed by detailed CNC machining for intricate furniture components, streamlining the overall furniture production process.

Investing in the Future of Furniture Manufacturing

By incorporating a horizontal beam saw (wood beam saw or big saw machine) from our company, the original factory of these machines, you gain a powerful tool for efficient and precise processing of lightweight furniture panels. Our advanced saws not only improve your production workflow and minimize waste but also unlock a world of creative possibilities for your furniture designs. Contact us today to learn more about how our cutting-edge technology can revolutionize your furniture production and empower you to bring your furniture design visions to life.