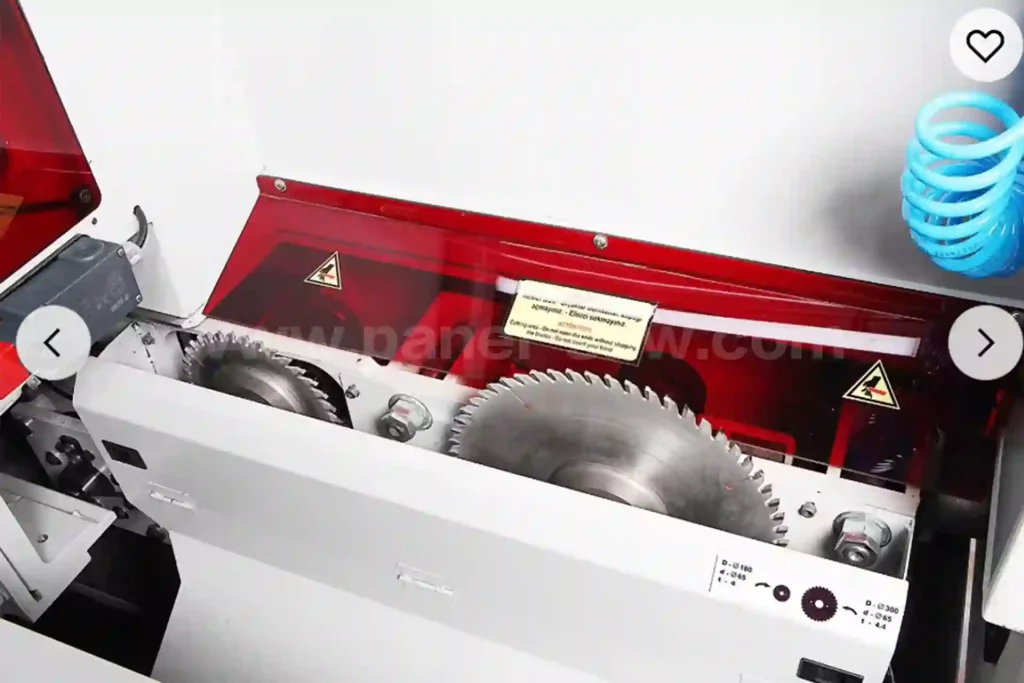

The 3800mm beam saw, a powerhouse among wood cutting machines, plays a vital role in high-volume woodworking operations. This cutting saw machine tackles large wood panels with exceptional precision, but have you ever wondered what goes into crafting such a machine? Let’s delve into the meticulous manufacturing process behind the 3800mm beam saw, showcasing the dedication to quality and durability that goes into every machine we produce.

The Heart of the Machine: Building the Beam Saw Framework

The beam saw framework serves as the foundation of the entire machine. Here’s a closer look at the steps involved in its creation:

- High-Strength Steel Selection: The process begins with the meticulous selection of premium-grade steel, chosen specifically for its exceptional strength and dimensional stability.

- Precise Steel Cutting: State-of-the-art cutting equipment ensures clean and accurate cuts in the steel components.

- Welding Expertise: Highly skilled welders meticulously join the steel components using advanced welding techniques to create a robust and stable foundation.

- Stress Relief Through Annealing: The welded framework undergoes a controlled annealing process to relieve stress and prevent warping, ensuring long-term stability.

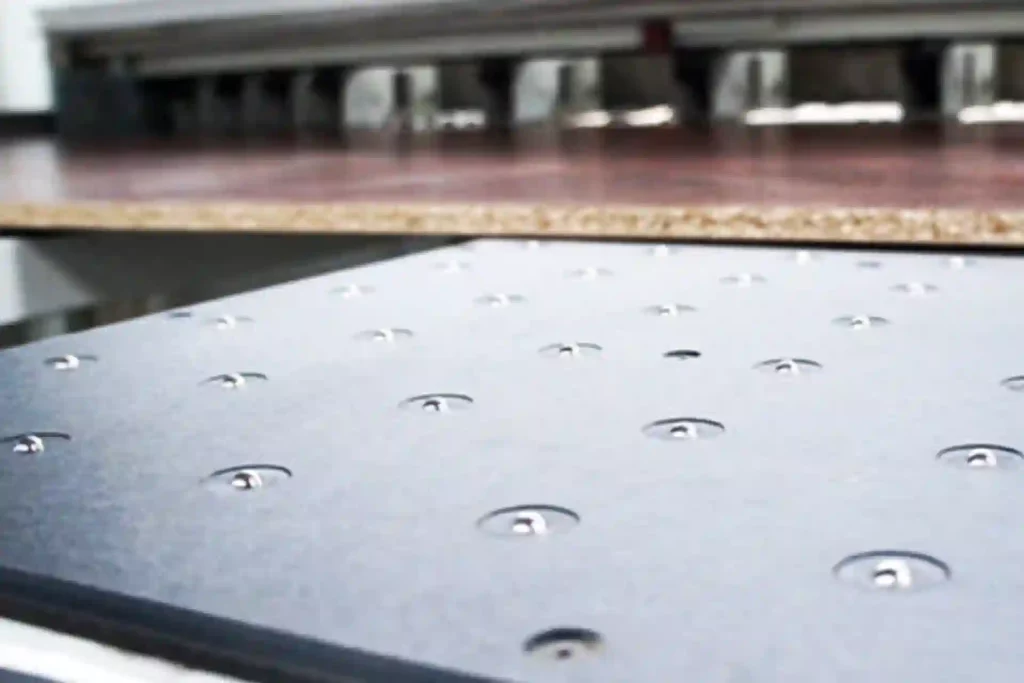

- Precision Machining: CNC machining centers precisely machine the framework components to achieve exact tolerances and smooth surfaces for optimal performance.

- Final Welding and Quality Control: After machining, any additional welding is performed, followed by rigorous quality control inspections to guarantee the structural integrity of the framework.

- Durable Painting: A multi-stage painting process coats the framework with a high-quality, industrial-grade paint that protects against corrosion and ensures a lasting finish.

Beyond the Framework: Crafting Additional Components

The meticulous approach extends to all sheet metal parts, including the panel pressing beam and manipulator beams. These components are precisely shaped according to detailed engineering specifications. They then undergo surface treatment through phosphating, powder coating, or painting to enhance corrosion resistance and aesthetics.

Bringing it All Together: Final Assembly and Software Integration

In the final stages, all electrical parts and accessories are meticulously prepared and integrated with the framework. Skilled technicians then perform the final assembly, ensuring all parts function flawlessly together. Finally, our software experts install and commission the operating system, guaranteeing the saw is ready to operate at peak performance upon arrival at your workshop.

A Commitment to Quality and Performance

By following this rigorous manufacturing process, we ensure that every 3800mm beam saw delivered to our customers is built to the highest standards. This commitment to quality translates into a machine that is not only powerful and precise but also built to last.

Considering a 3800mm Beam Saw for Your Woodworking Operation?

If you’re looking for a wood cutting machine that can handle large-scale panel cutting with exceptional efficiency and precision, the 3800mm beam saw might be the perfect solution for you. Contact us today to learn more about this innovative machine and how it can revolutionize your woodworking production.