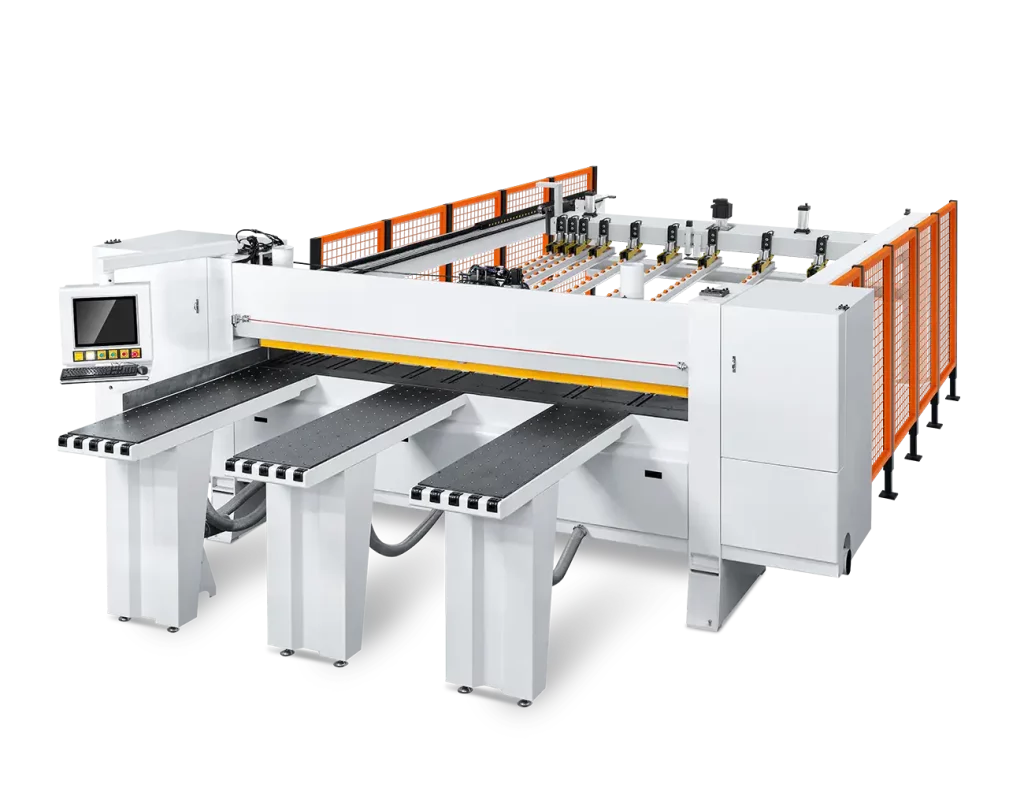

Elevate Your Brand with OEM CNC Panel Saws

As a premier OEM CNC Panel Saw manufacturer, we offer comprehensive OEM services for global customers. We’ll work closely with you to manufacture high-quality CNC panel saws that proudly bears your brand name. This allows you to:

- Strengthen Brand Recognition: Establish a strong presence in your local market with a machine that reflects your brand identity.

- Differentiate Yourself from Competitors: Offer a unique solution that caters to the specific needs of your customers.

- Boost Customer Loyalty: Provide a superior user experience with a machine designed for optimal performance and efficiency.

Uncompromising Performance with Advanced Features:

Our OEM CNC panel saws are built to deliver exceptional performance and reliability, even in demanding production environments. These machines incorporate a range of advanced features, including:

- High-Quality Components: German-type saw shafts, separate structures for large and small saws, and overall trolley designs ensure clean cuts, optimal performance, and long-lasting durability.

- Enhanced User Experience: Extended floating tables, high-pressure dust collection systems, and independent high-precision linear guide rails create a user-friendly and efficient workflow.

- Advanced Functionality: Quick disassembly of saw blades, trolley servo motor drives, and dust-proof guide rail designs offer increased productivity and operator comfort.

- Double-Claw Manipulator and Double-Bearing Feeding Wheel: These features ensure stability and smooth material handling for small workpieces and heavy loads.

OEM CNC Panel Saw Factory with proven performance

Now we have provided OEM for many woodworking machinery dealers, they had traded our OEM CNC Panel Saws to global market, covering the Indonesia, Malaysia, United States, Germany, Russia, Vietnam, Kazakhstan, Lebanon, Brazil, Australia, Belarus, South Korea, Thailand, Slovakia, the Philippines, Africa, Hungary, and other countries. we’ve been a trusted partner for our local and global dealers.

Unleash Your Design Vision: The Power of OEM Customization

OEM CNC Panel Saw customization goes beyond branding. We work with you to design a machine that perfectly integrates into your existing workflow and addresses your specific production needs. This may involve:

Beyond customization, we offer comprehensive after-sales support, including installation, training, and ongoing maintenance services. Our dedicated team is here to ensure you get the most out of your OEM CNC panel saw for years to come.

Ready to Take Your woodworking machinery Business to the Next Level?

Request an OEM CNC Panel Saw Quote today! Our experienced team will guide you through the customization process and help you design a machine that empowers you to achieve your business goals. With a customized OEM CNC panel saw from our factory, you can streamline production, enhance efficiency, and establish a strong brand identity in your local market. Contact us today and let’s create the perfect solution for your furniture business.

Applications

OEM CNC Panel Saw Applications: Choosing the Right Tool for the Job

When it comes to panel cutting in woodworking, there are two primary solutions: CNC nesting machines and computer beam saws.

- CNC Nesting Machines: These machines excel at intricate cuts and complex shapes. They utilize industrial computer control systems for enhanced precision and automation.

- Computer Beam Saws: These saws specialize in straight and batch cuts on wood panels and sheets. They are renowned for their exceptional cutting accuracy and smooth finishes.

Our computer beam saws embody these advantages perfectly. With over 12 years of experience, we design and manufacture top-of-the-line CNC panel saws trusted by woodworking businesses worldwide. Our computer beam saws are a popular choice for furniture production in countless woodworking plants and factories.

Manufacturing Procedures of OEM CNC Panel Saw Machine

The Craftsmanship Behind the OEM CNC Panel Saw

Our factory prioritizes quality and durability in every machine we produce. The High-Speed Intelligent OEM CNC Panel Saw is no exception. Here’s a detailed look at the meticulous production process that goes into crafting the OEM CNC Panel Saw framework, the heart of this powerful tool:

- High Strength Steel Selection: The process begins with the meticulous selection of high-grade steel specifically chosen for its strength and dimensional stability.

- Precise Steel Cutting: State-of-the-art cutting equipment ensures clean and accurate cuts in the steel components.

- Welding Expertise: Highly skilled welders meticulously join the steel components using advanced welding techniques to create a robust and stable foundation.

- Annealing for Stress Relief: The welded framework undergoes a controlled annealing process to relieve stress and prevent warping, ensuring long-term stability.

- Precision Machining: CNC machining centers precisely machine the framework components to achieve exact tolerances and smooth surfaces for optimal performance.

- Final Welding and Quality Control: After machining, any additional welding is performed, followed by rigorous quality control inspections to guarantee the structural integrity of the framework.

- Durable Painting: A multi-stage painting process coats the framework with a high-quality, industrial-grade paint that protects against corrosion and ensures a lasting finish.

This meticulous approach is extended to all sheet metal parts, including the panel pressing beam and manipulator beams. These components are precisely shaped according to detailed engineering specifications. They then undergo surface treatment through phosphating, powder coating, or painting to enhance corrosion resistance and aesthetics.

In the final stages, all electrical components and accessories are meticulously prepared and integrated with the framework. Skilled technicians then perform the final assembly, ensuring all parts function flawlessly together. Finally, our software experts install and commission the operating system, guaranteeing the saw is ready to operate at peak performance upon arrival at your workshop.

CNC Panel Saw Manufacturer Information

As a professional manufacturer for the CNC wood cutting machine, we can provide the one-stop solution for our customer regarding their wood sizing needs.

To make our customer satisfied with us, we have prepared enough talents such as machine design technician with over 20 years experiences in woodworking industry, as well as assembly workers with over 10 years experiences, to produce high-quality Computer Beam Saws, we not only provide the standard machine like 2800/3300 CNC Panel Saw, 3800 CNC wood cutting machine, but also provide custom machines like 4600mm beam saws.

For the sake of our customers, we also have trained lots of experienced workers to assemble the machines, and finish the whole process of manufacturing qualified beam saws. Here is what we can offer as below:

- Fast delivery lead time. We have a SOP (Standard Operation Procedure) regarding assembling standard CNC Panel Saws, therefore we can manufacture standard Computer Beam Saws fastest within 15 days.

- RTS CNC Panel Saws. We also have certain amount of ReadyToShip CNC wood cutting machines in our factory. For urgent demand, we can deliver RTS to global customers.

- Free technical design services. Our technician can make CAD drawing for your production cell, or for your customized CNC Panel Saw machines. Which will also make you very professional when facing your end customers.

- Customization CNC Panel Saw. We can do OEM/ODM service, this is one of our big advantages that make us different from our competitors. Tell us your special sizing demands, or needs, and we can provide the professional service for you.

- Competitive price. As original saw machine manufacturer, we are the best choice for global dealers, you would get the first-hand agent price from us, which will make you competitive upon the market.

- Strict quality control, we will check all the raw material when we got them from our vendors, and all the finished products once the production is completed.

- Best customer service, our sales will provide their help when customer send us the requests, and our technician will also involve in once you have any technical or customization requirement.