China Horizontal Beam Saws for Laminate Flooring Installation

Improve your woodworking projects with the power of horizontal beam saws

Laminate flooring, a popular choice for homeowners and businesses alike, offers a beautiful and durable alternative to traditional hardwood floors. However, achieving seamless installation requires precise cutting of laminate planks. Here’s where a horizontal beam saw, also known as a CNC beam saw, comes in. These specialized saws offer superior cutting performance and efficiency, ensuring clean and accurate cuts for a flawless laminate flooring installation.

What is Laminate Flooring Material?

Laminate flooring is a multi-layered composite material designed to mimic the appearance of wood, stone, or tile. The typical structure of a laminate plank includes:

- Wear layer: A transparent, wear-resistant top layer protects the plank from scratches, stains, and fading.

- Decorative layer: A high-resolution image layer replicates the appearance of wood grain, stone patterns, or other desired finishes.

- HDF (High-Density Fiberboard) core: This core layer provides stability, strength, and dimensional stability to the plank.

- Backing layer: A moisture-resistant backing layer balances the plank and prevents warping.

Features of Laminate Flooring Material

- Durability: Laminate flooring offers good resistance to scratches, stains, and fading, making it suitable for high-traffic areas.

- Affordability: Compared to solid hardwood flooring, laminate offers a more cost-effective option while still providing a realistic aesthetic.

- Easy Installation: Laminate flooring planks utilize a click-lock system for easy and fast installation, making it a DIY-friendly option for homeowners.

- Variety: Laminate flooring comes in a vast array of colors, patterns, and textures, allowing for design flexibility to match various aesthetic preferences.

How Horizontal Beam Saws (CNC Beam Saws) are Utilized in Cutting Laminate Flooring Material

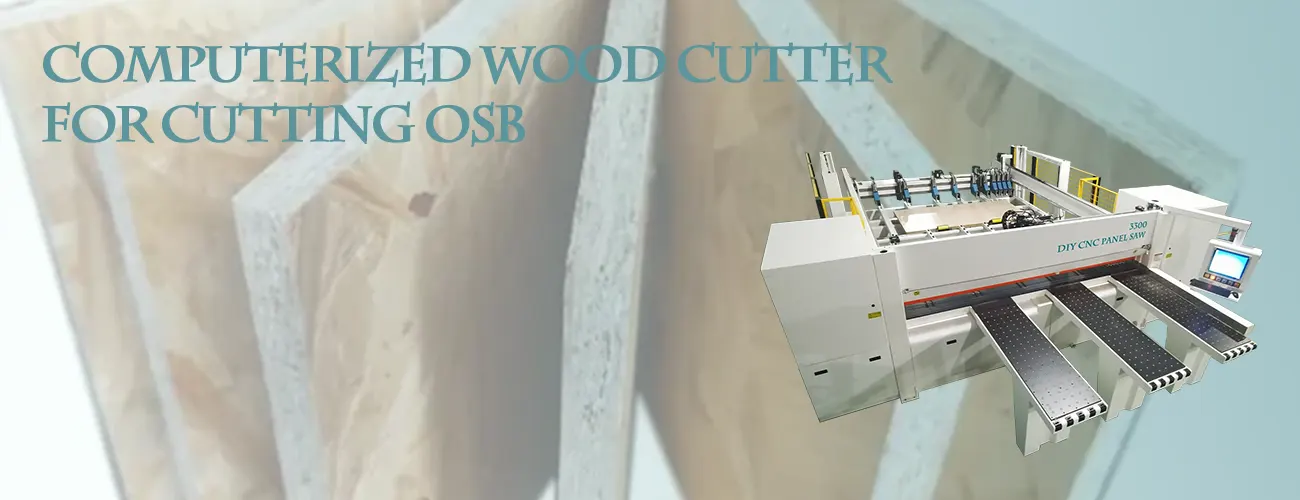

Horizontal beam saws, also known as CNC beam saws, are specifically designed for efficient and precise cutting of panel materials, including laminate flooring planks. Here’s how these advanced saws empower seamless laminate flooring installation:

- Automated Cutting Processes: CNC beam saws are computer-controlled, allowing for precise programming of cutting parameters like length, width, and angle. This automation eliminates human error and ensures consistent, repeatable cuts for a perfect fit.

- High-Precision Cutting Systems: The saws utilize high-quality blades and sophisticated cutting systems to achieve clean and chip-free cuts. This precision cutting minimizes damage to the laminate surface, preserving the aesthetic appeal and preventing premature wear of the planks.

- Dust Extraction Systems: Integrated dust extraction systems effectively capture dust particles generated during the cutting process. This promotes a clean working environment and minimizes the risk of airborne allergens, particularly important for those with respiratory sensitivities.

- Batch Cutting Capabilities: Horizontal beam saws excel at handling large quantities of laminate flooring material. Operators can program multiple cuts simultaneously, allowing for efficient batch processing of planks for large installation projects.

The Advantages of Our Horizontal Beam Saws (CNC Beam Saws) in Sizing Laminate Flooring Material

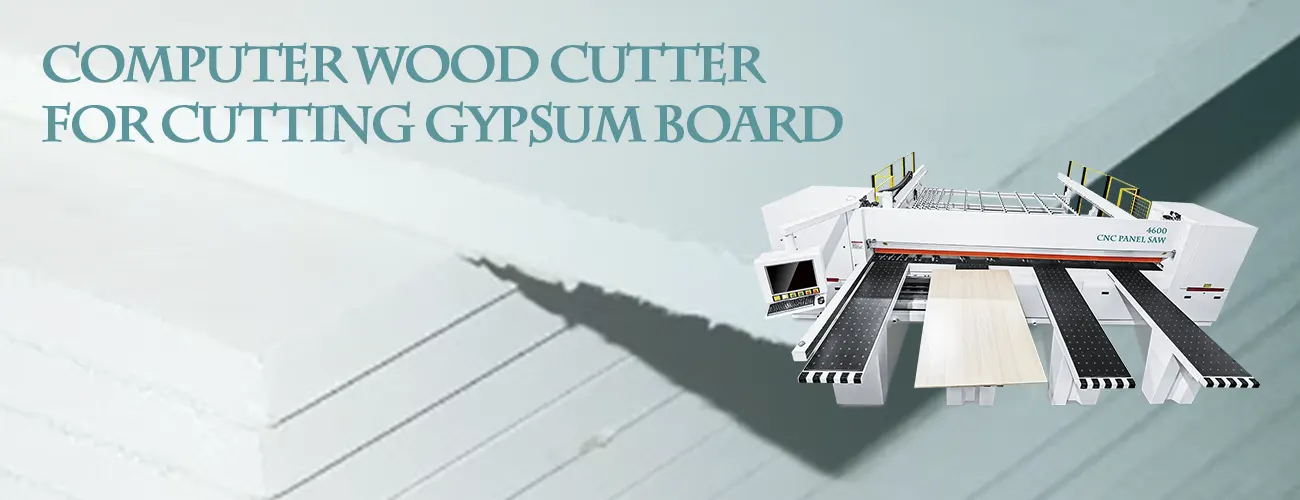

Investing in a dedicated horizontal beam saw (CNC beam saw) from our company offers several advantages for efficient and professional laminate flooring installation:

- Superior Cutting Performance: Our industrial-grade saws ensure clean and accurate cuts, minimizing waste and preserving the integrity of your laminate flooring planks. This translates to a professional-looking installation with minimal rework required.

- Enhanced Installation Efficiency: The automated cutting processes and batch processing capabilities of our horizontal beam saws significantly reduce cutting times compared to manual methods. This translates to faster project completion and increased productivity for professional installers.

- Reduced Material Waste: Precision cutting systems minimize scrap material, allowing you to optimize the use of your laminate flooring planks. This not only saves you money on materials but also promotes sustainable resource utilization practices.

- Versatility for Different Projects: Our horizontal beam saws can handle various laminate flooring plank sizes and thicknesses, making them suitable for diverse installation projects, from small bathrooms to expansive living areas.

- User-Friendly Operation: Our saws are designed with user-friendly interfaces and intuitive controls. This makes them easy to operate, even for workers with limited experience operating CNC machinery.

Elevate Your Laminate Flooring Installation with Precision Cutting

Investing in a reliable horizontal beam saw (CNC beam saw) can significantly improve the quality and efficiency of your laminate flooring installation projects. Our advanced saws empower you to achieve superior cutting performance, streamline your workflow, and minimize material waste. Contact us today to learn more about how our CNC beam saws can revolutionize your approach to laminate flooring installation and ensure a flawless, professional finish for your projects.