Realize Efficiency: Automated Wood Cutting Machines for Efficient Laminated Wood Processing

Improve your woodworking projects with the power of Automated Wood Cutting Machine

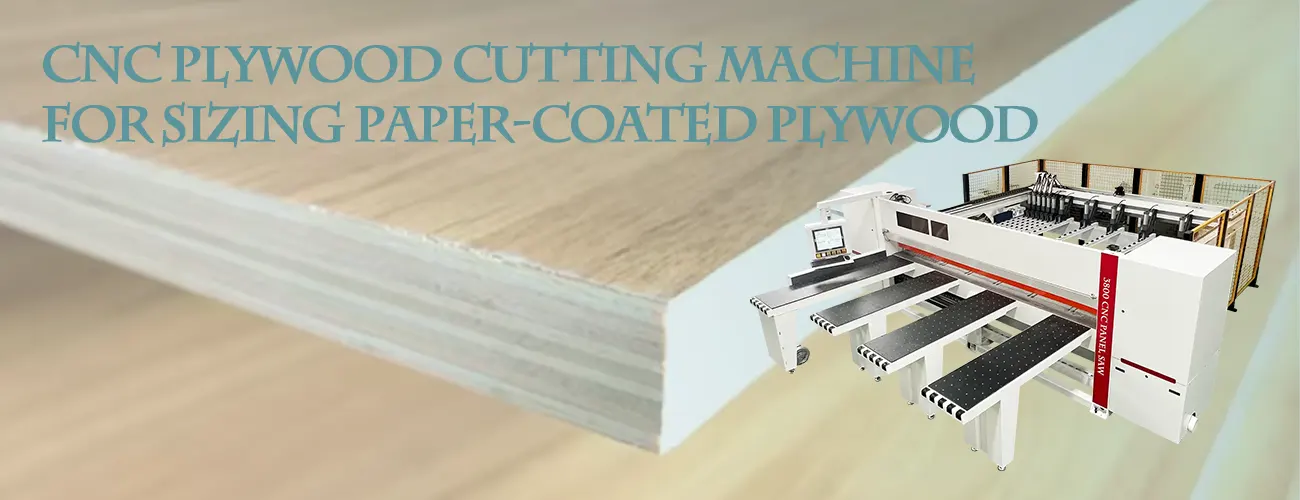

Laminated wood, a versatile and high-performance material, is increasingly used in furniture construction, cabinetry, and various architectural applications. However, achieving the desired shapes and sizes for laminated wood components requires precise cutting techniques. Here’s where automated wood cutting machines, also known as CNC woodcutters or saws for wood, come into play. These advanced machines offer unparalleled accuracy, efficiency, and control for cutting laminated wood, ensuring a flawless finish for your projects.

What is Laminated Wood?

Laminated wood is an engineered wood product composed of multiple wood layers bonded together with adhesive. The individual layers, typically made from veneers or solid wood pieces, can be arranged in various configurations to achieve desired strength, aesthetics, and dimensional stability. This versatility makes laminated wood a popular choice for a wide range of applications.

Features of Laminated Wood:

- Strength and Stability: The layered structure of laminated wood offers superior strength and dimensional stability compared to solid wood. This makes it ideal for applications requiring high load-bearing capacity and minimal warping or shrinkage, such as beams, countertops, and shelving.

- Versatility: Laminated wood allows for customization in terms of size, thickness, and appearance. By using different wood species or veneer finishes for each layer, designers and woodworkers can achieve unique visual effects and cater to specific project requirements.

- Sustainability: Laminated wood allows for efficient utilization of smaller wood pieces, minimizing waste and promoting sustainable forestry practices. This becomes particularly relevant as responsible resource management gains importance.

- Moisture Resistance: The adhesive used in laminated wood construction enhances its moisture resistance compared to solid wood. This improved resistance makes it suitable for applications with moderate humidity exposure, such as kitchens and bathrooms.

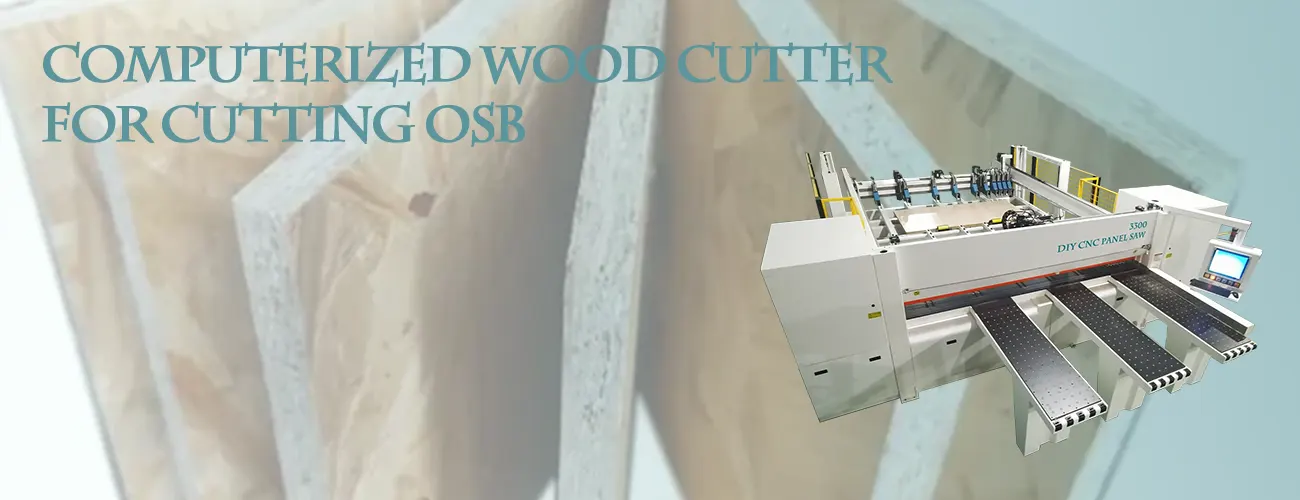

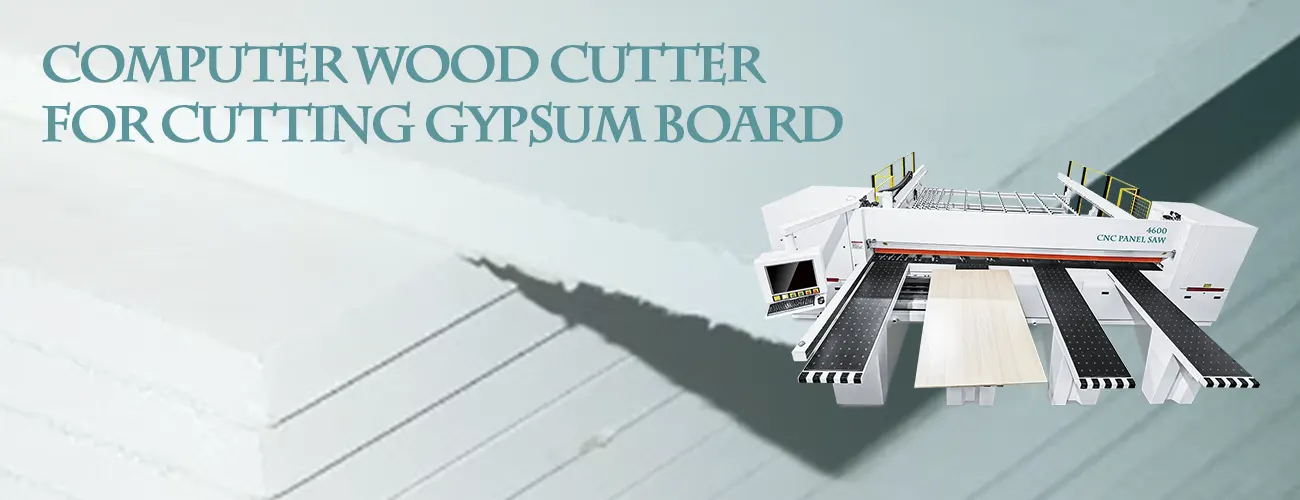

How Automated Wood Cutting Machines (CNC Woodcutters) are Utilized in Cutting Laminated Wood

Automated wood cutting machines, also known as CNC woodcutters, are revolutionizing the process of cutting laminated wood. Here’s how these advanced machines empower precise and efficient laminated wood processing:

- Computerized Control (CNC): CNC woodcutters utilize computer-aided design (CAD) software to program cutting paths. This allows for precise programming of cut shapes, sizes, and angles, ensuring consistent and repeatable cuts for all laminated wood components.

- High-Precision Cutting Systems: These machines integrate high-quality cutting tools, such as router bits or saw blades, along with advanced cutting systems for optimal control. This translates to clean and chip-free cuts that minimize damage to the laminated layers, preserving the aesthetic appeal and structural integrity of the material.

- Dust Extraction Systems: Integrated dust extraction systems effectively capture dust particles generated during the cutting process. This maintains a clean working environment for operators, minimizes the risk of respiratory irritation, and allows for better visibility during cutting operations.

- Nesting Capabilities: Advanced CNC woodcutters boast nesting capabilities. This software feature optimizes material usage by arranging multiple cuts within the laminated wood sheet, minimizing scrap and maximizing material utilization.

Advantages of Our Automated Wood Cutting Machines (CNC Woodcutters) in Sizing Laminated Wood

Investing in a dedicated automated wood cutting machine (CNC woodcutter) from our company offers several advantages for efficient and precise laminated wood processing:

- Superior Cutting Performance: Our industrial-grade CNC woodcutters ensure clean and accurate cuts, minimizing waste and preserving the integrity of your laminated wood. This translates to a professional-looking finished product with minimal rework required, saving you time and resources.

- Enhanced Workflow Efficiency: The automation, precision, and nesting capabilities of our CNC woodcutters significantly reduce cutting times compared to manual methods. This translates to faster project completion, improved production throughput, and increased productivity for your woodworking operation.

- Reduced Material Waste: Precision cutting systems and nesting features minimize scrap material, allowing you to optimize the use of your laminated wood sheets. This not only reduces material costs but also aligns with responsible resource management practices.

- Versatility for Diverse Projects: Our CNC woodcutters can handle various laminated wood sizes and thicknesses, as well as complex shapes and intricate designs. This versatility makes them suitable for a wide range of woodworking and fabrication projects, from furniture parts to architectural elements.

- Scalability for Growing Businesses: CNC woodcutters offer scalability for businesses of all sizes. As your production demands increase, these machines can adapt to handle larger workloads and more complex projects, supporting your business growth.

Beyond Efficiency: The Creative Potential of CNC Woodcutters

While the efficiency gains are undeniable, the benefits of CNC woodcutters extend beyond simply cutting laminated wood faster and with less waste. These machines unlock a whole new realm of creative possibilities for woodworkers and designers:

- Intricate Designs: The precise control and repeatability of CNC woodcutters allow for the creation of intricate and detailed designs on laminated wood. This opens doors for incorporating intricate patterns, lettering, or logos into furniture pieces, wall panels, or architectural elements, adding a unique touch to your projects.

- Complex Joinery: CNC woodcutters excel at creating complex joinery for laminated wood components. This allows for the creation of strong and visually appealing joints, such as box joints, finger joints, or dovetails, with perfect precision. This elevates the structural integrity and aesthetic appeal of your laminated wood projects.

- Curved Designs: Advanced CNC woodcutters can be equipped with specialized tooling for curved cuts. This allows for the creation of curved laminated wood components, perfect for furniture with rounded edges, architectural elements like arches or columns, or decorative pieces with flowing curves.

- Inlay and Marquetry Techniques: CNC woodcutters can be used for precise cutting of inlay and marquetry components. These traditional techniques involve embedding contrasting wood pieces into a laminated wood base to create intricate patterns or artwork. The precision cutting capabilities of CNC woodcutters streamline this process and allow for the creation of stunning decorative elements.

- Prototyping and Design Exploration: The ability to quickly and accurately cut laminated wood prototypes makes CNC woodcutters ideal for design exploration and product development. This allows woodworkers and designers to experiment with different shapes, sizes, and joinery methods before committing to final production runs, saving time and material during the design process.

Investing in the Future of Laminated Woodworking

By incorporating automated wood cutting machines (CNC woodcutters) into your woodworking operation, you gain a powerful tool for efficient and precise laminated wood processing. Our industrial-grade CNC woodcutters not only streamline your workflow and minimize waste but also unlock a world of creative possibilities. Contact us today to learn more about how our advanced CNC technology can revolutionize your approach to laminated wood cutting and empower you to bring your woodworking visions to life.