Improve your woodworking capabilities with a CNC wood cutting solution tailored to your specific needs.

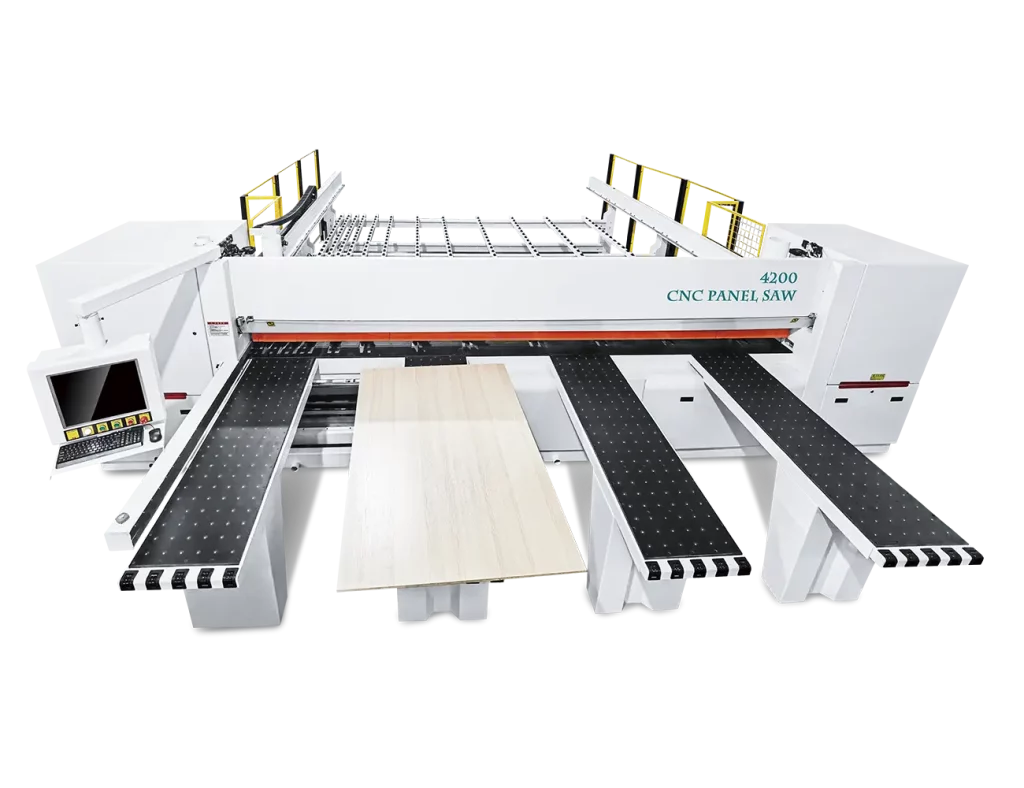

The 4200mm CNC Wood Cutting Machine addresses a common challenge faced by many woodworking businesses: the need for a machine that can handle oversized wood panels.

4200mm CNC Wood Cutting Machine Specifications: Designed for Large Panel Processing

While a 4200mm cutting width is not a standard size, it’s a highly sought-after feature for businesses working with large-scale projects. This customized CNC wood cutter offers a perfect solution for those who require exceptional cutting capacity:

- Unmatched Cutting Size: With a maximum cutting width of 4200mm, this machine eliminates the need for panel splitting in most cases, optimizing material utilization and production efficiency.

- Customized Design: We understand that every woodworking operation has unique requirements. This machine can be customized to your specific needs, ensuring a solution that seamlessly integrates into your workflow.

4200mm CNC Wood Cutting Machine Features: Power Meets Precision

The 4200mm CNC Wood Cutting Machine is packed with advanced features designed to deliver exceptional performance and user-friendliness:

- Advanced Technology: Built with cutting-edge technology, this machine is engineered for long-term reliability and smooth operation, even under demanding workloads.

- German-type Saw Shaft: Experience clean and precise cuts with a high-quality German-type saw shaft.

- Large and Small Saws with Separate Structures: This configuration ensures optimal cutting performance for various material thicknesses.

- Overall Trolley Design: This design enhances stability and cutting accuracy.

- Extended Floating Table: The extended table simplifies material handling, reducing operator workload and saving manpower.

- High-pressure Fan: An efficient dust collection system maintains a clean working environment.

- Independent High-precision Linear Guide Rail: This feature guarantees consistent cutting precision during saw lifting.

- Quick Disassembly of Saw Blades: This design allows for swift and easy blade changes, minimizing downtime.

- Trolley Servo Motor Drive: This advanced drive system provides smooth and precise movement of the cutting carriage.

- Dust-proof Guide Rail Design: The guide rails are installed parallel to the outside, preventing dust accumulation and ensuring smooth operation.

- Double-claw Manipulator: This feature provides enhanced stability when handling smaller workpieces.

- Double-bearing Feeding Wheel: This heavy-duty feeding system ensures smooth material handling for even the most challenging workloads.

Applications

CNC Wood Cutting Applications: A Versatile Solution for Diverse Projects

CNC wood cutting machines offer a wide range of applications in the woodworking industry. The 4200mm model, with its exceptional cutting capacity, is particularly suited for projects that involve large wood panels, such as:

- Furniture production: Efficient cutting of oversized panels for cabinets, tables, and other large furniture components.

- Architectural woodworking: Fabrication of wooden elements for walls, ceilings, and other large-scale architectural projects.

- Exhibition and stage design: Precise cutting of wood panels for building sets, displays, and other stage elements.

- … and many more!

Manufacturing a Customized CNC Wood Cutting Machine

A Commitment to Quality

The 4200mm CNC Wood Cutting Machine undergoes a meticulous manufacturing process that prioritizes quality and durability. Here’s a glimpse into the key steps involved:

- Custom Designing: Due to the large size of the panel saw, the CNC cutting machinery need to be custom designed. With the rich experience, our factory has mature experience and tailor-designs.

- High-Strength Steel Selection: The framework is constructed using premium-grade steel, ensuring exceptional strength and dimensional stability.

- Precision Manufacturing: State-of-the-art equipment and techniques guarantee precise component creation and assembly.

- Advanced Features Integration: Cutting-edge technology and high-quality components are incorporated to deliver optimal performance.

- Rigorous Testing and Commissioning: The machine undergoes thorough testing to ensure it meets all performance and safety standards before delivery.

By investing in a customized 4200mm CNC Wood Cutting Machine, you’re not just acquiring a machine; you’re gaining a reliable partner that empowers you to tackle large-scale woodworking projects with confidence and efficiency. Contact us today to discuss your specific requirements and learn more about how this innovative machine can transform your woodworking capabilities.

CNC wood cutting machine Manufacturer Information

As a professional manufacturer for the wood cutting machinery, we can provide the one-stop solution for our customer regarding their wood sizing needs.

To make our customer satisfied with us, we have prepared enough talents such as machine design technician with over 20 years experiences in woodworking industry, as well as assembly workers with over 10 years experiences, to produce high-quality CNC wood cutter, we not only provide the standard machine like 2800/3300 CNC wood cutting machine, 3800 cutting machinery, but also provide custom machines like 4600mm beam saws.

For the sake of our customers, we also have trained lots of experienced workers to assemble the machines, and finish the manual working. Here is what we can offer as below:

- Fast delivery lead time. We have a SOP (Standard Operation Procedure) regarding assembling standard CNC wood cutting machines, therefore we can manufacture standard CNC wood cutters fastest within 15 days.

- RTS CNC wood cutting machines. We also have certain amount of ReadyToShip cutting machinery in our factory. For urgent demand, we can deliver RTS to global customers.

- Free technical design services. Our technician can make CAD drawing for your production cell, or for your customized CNC wood cutting machine machines. Which will also make you very professional when facing your end customers.

- Customization CNC wood cutting machine. We can do OEM/ODM service, this is one of our big advantages that make us different from our competitors. Tell us your special sizing demands, or needs, and we can provide the professional service for you.

- Competitive price. As original saw machine manufacturer, we are the best choice for global dealers, you would get the first-hand agent price from us, which will make you competitive upon the market.

- Strict quality control, we will check all the raw material when we got them from our vendors, and all the finished products once the production is completed.

- Best customer service, our sales will provide their help when customer send us the requests, and our technician will also involve in once you have any technical or customization requirement.