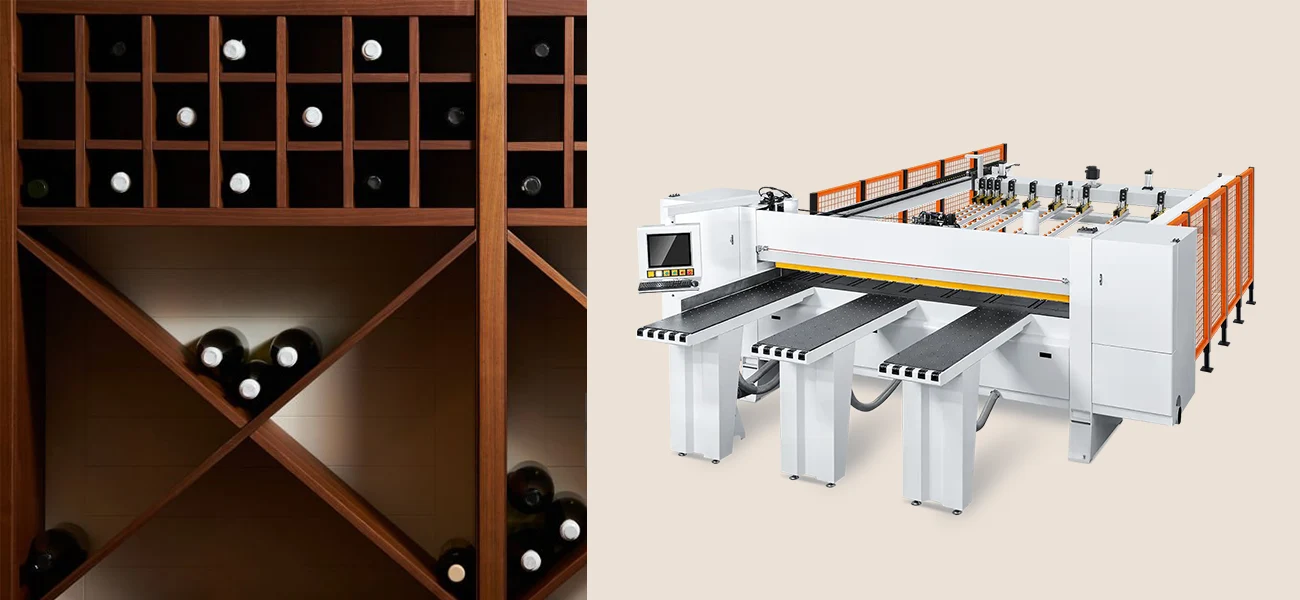

China Original Supplier for Kitchen Cabinet Saw, Computerized Cabinet Saw for Sale

Looking to optimize your kitchen cabinet production? Look no further than our factory, a leading original supplier of CNC cabinet saws in China. We understand the importance of precision, efficiency, and quality in every stage of furniture making, particularly during material preparation, the first and critical step.

From Raw Wood to Culinary Canvas: The Kitchen Cabinet Creation Process

The transformation of raw materials into the organized haven of your dream kitchen is a remarkable journey. Here’s a behind-the-scenes look at the key stages involved in kitchen cabinet creation:

- Designing Your Dream Kitchen: The process begins with capturing your vision. Skilled designers translate your ideas and preferences into detailed blueprints, ensuring both aesthetics and functionality. They consider factors like storage needs, ergonomic flow, and efficient use of materials to create a kitchen layout that perfectly complements your culinary endeavors.

- Engineering for Functionality: Skilled engineers meticulously plan the construction process, focusing on the structural integrity and stability of each cabinet unit. This stage optimizes material usage to minimize waste and ensures the cabinets can withstand everyday wear and tear.

- Prototyping: A Test Run Before Full Production: Before large-scale production commences, a prototype cabinet may be created. This physical model allows for design refinement, testing functionality like drawer movement and door alignment, and identifying any potential issues before full production begins.

- The Production Hub: Transforming Materials into Cabinets: Production is the bustling center of cabinet creation, involving several crucial steps:

- Material Preparation: The journey starts with raw materials like wood. Skilled workers or automated machinery meticulously cut, shape, and sand the wood according to pre-defined specifications. This stage sets the foundation for every cabinet component.

- Assembly Expertise: The prepped components are then meticulously assembled based on the technical drawings. Skilled workers or automated machinery carefully bring the individual cabinet pieces together to form functional units.

- Finishing Touches: Beauty Meets Protection: Here, the cabinets are adorned with a protective and aesthetically pleasing finish, such as paint, varnish, or stain. This step enhances the visual appeal of your cabinets while ensuring their durability.

- Quality Control: Ensuring Flawless Functionality: Trained inspectors conduct a rigorous quality control process. This includes visual inspections, functionality tests like drawer movement and door closure, and even load-bearing tests to guarantee the cabinets meet stringent standards for safety, functionality, and longevity.

- Packaging and Shipping: Once deemed flawless, the cabinets are carefully packaged to prevent damage during transportation. They then embark on their journey to distributors, retailers, or directly to you.

Beyond Delivery: Ensuring Customer Satisfaction

The commitment often extends beyond delivery. Some manufacturers offer after-sales services like installation, repair, or replacement of defective parts. This ensures your complete satisfaction and fosters a strong reputation for the manufacturer.

This glimpse into the intriguing process showcases the transformation of raw materials into the beautiful and functional kitchen cabinets that will house your culinary creations and enhance the heart of your home.

The Function of Cabinet Saws During the Process of Kitchen Cabinet Production

From the outlined process, it is clear that production is a pivotal step in kitchen cabinet manufacturing, with cutting during material preparation being the primary step that matters most. During this phase, our industrial cabinet saws play a significant role. These cabinet saws ensure precise cutting of materials, which is essential for the accurate assembly and high-quality finish of the final product.

The Features of Cabinet Saws

Our cabinet saws are designed with the following features to enhance the kitchen cabinet production process:

- Automated: Fully automated systems to increase efficiency and reduce manual labor.

- Computer Controlled: Precision control for accurate and consistent cuts.

- Intelligent: Smart features that optimize cutting processes and improve productivity.

- Proven Performance: Reliable and durable performance backed by extensive industry experience.

Complete models of Cabinet Saws

CNC panel saws used in kitchen cabinet production come in various models and sizes to meet different production needs. Available sizes include 2800mm, 3300mm, 3800mm, 4200mm, and 4600mm computer panel saws. Different regions or countries may have specific demands based on their unique needs.

By loading type, panel saws are categorized into front-loading and back-loading models. The back-loading panel saws also come in a wide range of sizes.

The most efficient cutting machine in this category is the angular panel saw, which performs horizontal and vertical cutting in one step. This enhances production efficiency, speeds up the process, and saves space. Our angular panel saws boast proven performance and share similar structures with renowned brands like Holzma panel saws and Schelling beam saws.

Discover our range of cabinet saws for sale and find the perfect solution to elevate your kitchen cabinet production process. Contact us to learn more about our products and services.