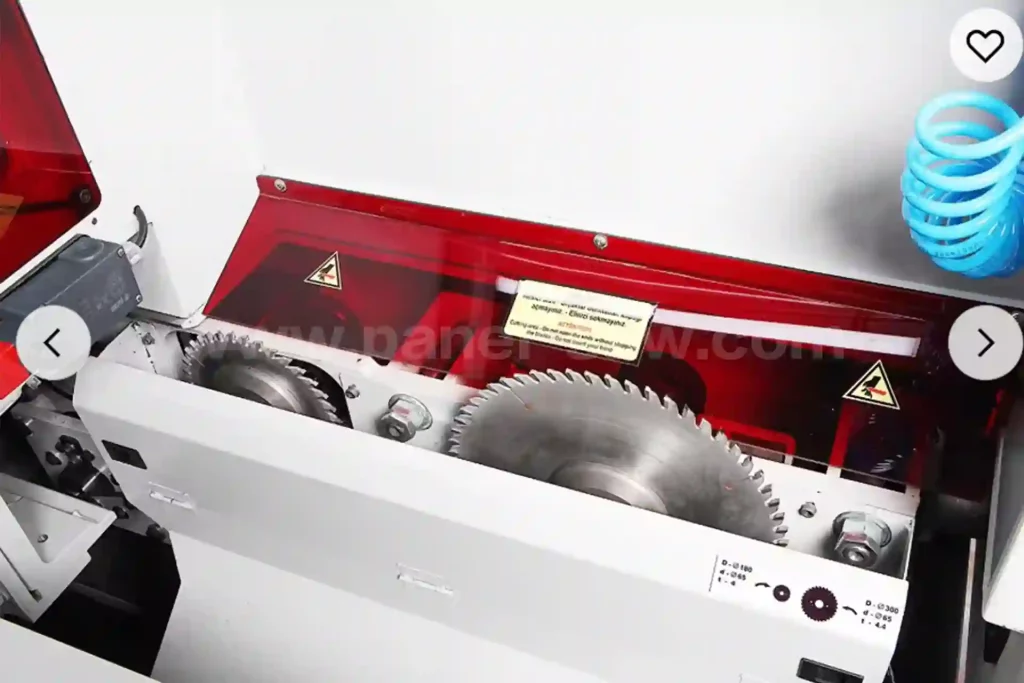

Revolutionize your cutting process

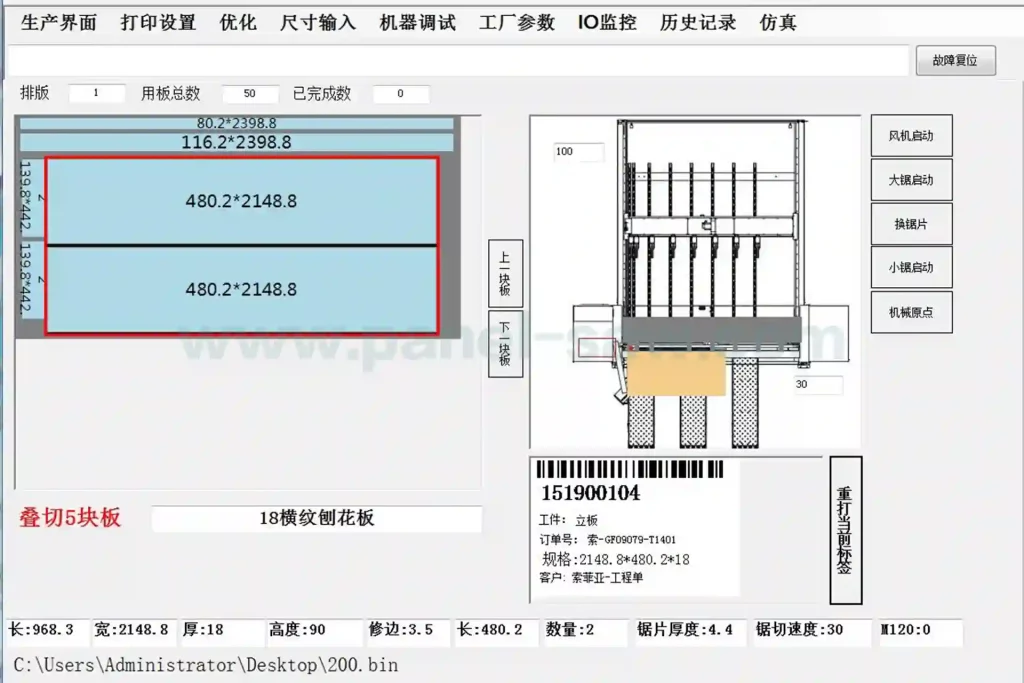

The latest computerized beam saw boasts intelligent data import, wireless remote control, and remote monitoring capabilities.

High efficiency of 2800mm Panel Saw

This computer beam saw goes beyond cutting. It offers a suite of practical functions like order design & optimization, remnant management, layout optimization, and barcode printing.

Experience Cutting-Edge Efficiency

The high-efficiency horizontal panel saw machine doesn’t just cut panels; it optimizes cutting plans and layouts with powerful programming functions, including real-world scenario simulation.